Table of Contents

Introduction

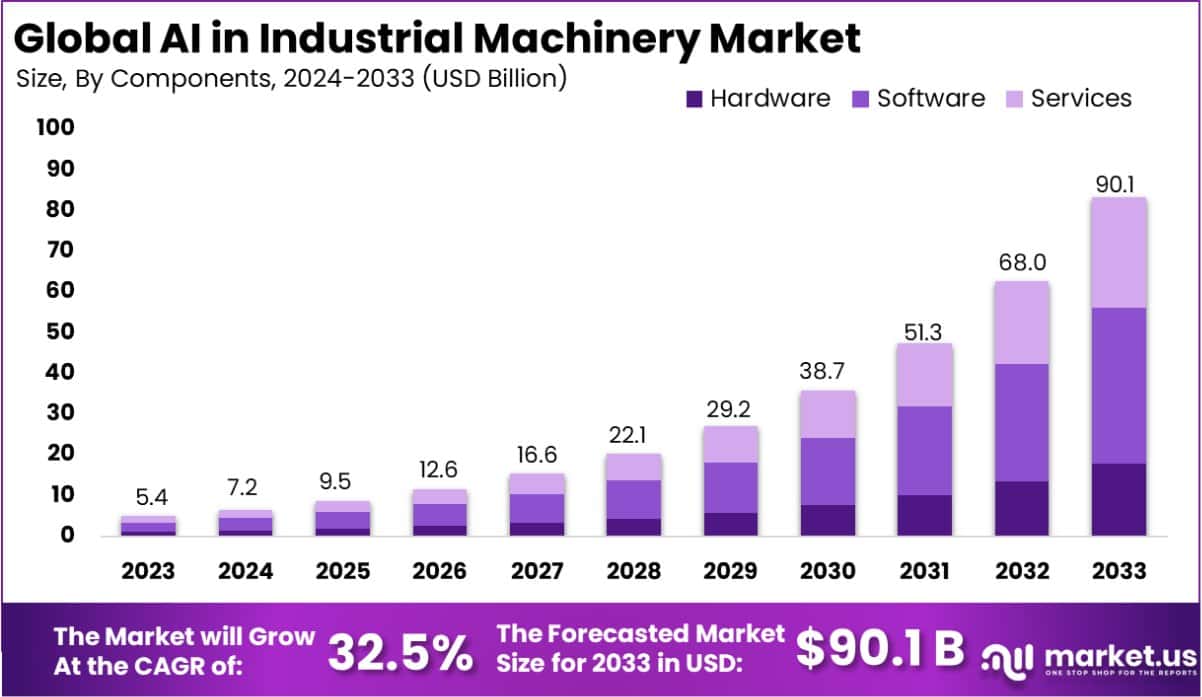

According to the Market.us, the global market for AI in Industrial Machinery is projected to increase from USD 5.4 billion in 2023 to around USD 90.1 billion by 2033, achieving a compound annual growth rate (CAGR) of 32.5% from 2024 to 2033.

Artificial Intelligence technologies are being integrated into various machinery and equipment to enable predictive maintenance, optimize manufacturing processes, and improve supply chain management. This integration involves the use of sensors, machine learning models, and advanced analytics to monitor equipment health, predict potential failures, and automate complex tasks.

The demand for AI in industrial machinery is driven by the need for automation and efficient operations across manufacturing sectors. Industries such as automotive, aerospace, and electronics are rapidly adopting AI technologies to stay competitive. The increasing emphasis on predictive maintenance and energy efficiency further fuels this demand, as companies seek to minimize unexpected machine downtimes and optimize energy usage in production processes.

The market for AI in industrial machinery is experiencing robust growth, propelled by technological advancements and the rising adoption of Industry 4.0 principles. As more businesses recognize the value of data-driven decision-making, investments in AI technologies continue to rise. This growth is also supported by governmental initiatives aimed at promoting smart manufacturing practices, which include substantial funding and incentives for technology upgrades.

There are substantial opportunities in developing AI solutions that are more adaptable and can be easily integrated with existing machinery. The ongoing trend towards customization and flexible manufacturing systems presents a lucrative avenue for AI applications. Moreover, there is a growing need for AI solutions that cater to smaller, mid-sized manufacturers who may not have the capital for large-scale AI implementations but are keen on optimizing their production lines for better efficiency and product quality. These factors highlight the expanding scope and potential for AI in the industrial machinery sector.

Key Takeaways

- The global AI in Industrial Machinery market is projected to grow from USD 5.4 billion in 2023 to USD 90.1 billion by 2033, with a compound annual growth rate (CAGR) of 32.5% from 2024 to 2033.

- In 2023, the Software component held a leading position in the AI in Industrial Machinery market, accounting for over 42.5% of the market share.

- Predictive Maintenance was the leading application in the AI in Industrial Machinery market in 2023, capturing more than 23.4% of the market share.

- The Commercial sector was the predominant end-user in the AI in Industrial Machinery market in 2023, holding more than 24.2% of the market share.

- In 2023, North America held the largest share of the AI in Industrial Machinery market, with 37.5% market share and revenues amounting to USD 2.02 billion.

AI in Industrial Machinery Statistics

- The Global Artificial Intelligence Market is poised for substantial growth, projected to expand from USD 177 billion in 2023 to approximately USD 2,745 billion by 2032, achieving a robust compound annual growth rate (CAGR) of 36.8% during the forecast period from 2024 to 2033.

- Within various sectors, the electronics and technology equipment industry emerges as the frontrunner in AI integration, with an adoption rate of 83%. This is notably higher than the energy sector at 72% and the process industry at 68%. AI’s proliferation across these sectors underscores its integral role in modern industrial applications.

- A significant majority of executives, 89%, acknowledge the critical importance of AI to their business operations, with plans to integrate AI technologies into their production processes. This strategic integration is primarily aimed at enhancing operational efficiency, sustainability, and workforce productivity.

- In the realm of manufacturing, executives have recognized AI’s transformative potential, with 64% identifying its capacity to significantly boost production efficiency. Additionally, AI is viewed as a key driver for advancing sustainability (53%), enhancing production flexibility (52%), and supporting the workforce (47%).

- A substantial proportion of executives, 68%, report the full implementation of at least one AI application within their operations. Among the various AI applications, quality control, especially those utilizing computer vision, is identified as the most advanced and relevant use case presently.

- Despite high adoption rates in sectors like electronics and technology equipment (83%), energy (72%), and process industry (68%), challenges in scaling AI applications persist. Only 16% of respondents have met their AI-related objectives, with a significant 98% indicating difficulties in scaling AI technologies across their operations.

- Geographically, AI implementation varies, with over half of European manufacturers (51%) actively deploying AI solutions, followed by Japan (30%) and the United States (28%). In manufacturing, the leading AI applications focus on enhancing maintenance (29% of cases) and improving quality control (27%), showcasing the technology’s broad impact on the industry.

Emerging Trends

- AI-Driven Automation in Manufacturing: The integration of AI in robots is transforming manufacturing by automating precision tasks, leading to increased safety, reduced costs, and improved efficiency. Companies like Siemens and Fanuc are leveraging AI to enhance automation and continuously monitor production environments.

- Enhanced Quality Control with AI: AI technologies are being increasingly used for quality assurance in manufacturing. Techniques like automatic image recognition help detect defects and irregularities in products, ensuring higher quality and consistency. AI’s role extends to monitoring production processes for optimization and continuous improvement.

- Predictive Maintenance: AI is being used to predict equipment failures before they occur, significantly reducing downtime. By analyzing data from IoT devices, AI can identify potential issues and schedule maintenance proactively. Companies like Danone and Thales SA use machine learning to optimize their operations and maintenance schedules.

- AI in R&D and Design Optimization: AI aids significantly in the research and development process by simulating and testing product designs virtually through digital twins. This accelerates innovation by allowing for rapid iteration and customization of product designs, thus reducing time-to-market and enhancing product performance.

- Condition Monitoring and Reliability: The use of AI for condition monitoring is proving crucial in detecting faults in machinery, especially in rotating equipment. New AI models are being developed that maintain high accuracy even under varying operational conditions, ensuring reliable operation and reducing unexpected failures.

Key Applications

- Automated Material Handling: AI improves the automation of material handling in manufacturing environments through the use of autonomous robots. These robots can navigate through warehouses and factories, picking and transporting materials as needed, which enhances logistics and reduces labor costs.

- Predictive Maintenance: AI leverages machine learning algorithms to predict machinery failures before they occur, thereby reducing downtime and maintenance costs. This is achieved by analyzing data from sensors and using it to forecast equipment malfunctions, allowing preemptive maintenance actions to be scheduled at convenient times without disrupting production.

- Quality Control: Computer vision AI applications are extensively used to automate and enhance quality control processes in manufacturing. These systems can identify defects and inconsistencies in products at a much higher accuracy and speed than human inspectors.

- Generative AI for Process Automation: This application involves using AI to generate program code from text inputs, which helps in automating and streamlining manufacturing processes. Generative AI can significantly accelerate the creation of process automation scripts, reducing the time and cost associated with manual programming.

- Enhanced Robotics: AI is being integrated into robotics to enable more autonomous operations. Robots equipped with AI can understand voice commands and perform tasks without the need for constant human supervision or frequent retraining. This technology is particularly useful in automating material handling and other repetitive tasks, leading to increased production efficiency.

Major Challenges

- Data Complexity and Poor Insights: Many companies are data-rich but struggle to extract meaningful insights due to the vast amount of unstructured data they collect. This makes it difficult to utilize AI effectively for decision-making processes.

- Talent Shortage: There is a notable gap in skilled professionals capable of managing and implementing AI technologies. This shortage is expected to affect about 90% of organizations by 2025, posing significant challenges to scaling AI applications in industrial settings.

- Integration and Scalability Issues: Despite the potential benefits of AI, many firms find it challenging to integrate and scale AI solutions across their operations. The transition from pilot projects to full-scale deployment often encounters significant hurdles.

- Economic and Geopolitical Pressures: Volatile resource prices, supply chain disruptions, and geopolitical instability further complicate the deployment of AI technologies. These factors can impede the consistent application and development of AI across global operations.

- Technological Fragmentation: AI implementations often suffer from fragmentation due to different standards, technologies, and the absence of a cohesive strategy. This can lead to inefficiencies and increased costs as companies struggle to unify their AI initiatives.

Market Opportunities

- Enhanced Predictive Maintenance: AI enables advanced predictive maintenance by analyzing data from machinery sensors in real-time, identifying potential issues before they cause significant downtime. This not only reduces maintenance costs but also increases equipment lifespan and efficiency.

- Increased Automation and Efficiency: AI is driving automation in industrial machinery by optimizing production processes and reducing human error. This leads to more efficient operations, lower costs, and the ability to scale production more effectively.

- Smart Robotics Integration: AI-powered robotics are increasingly being integrated into industrial processes, enabling more flexible and adaptive manufacturing environments. These smart robots can work alongside human workers or operate autonomously, increasing productivity and safety.

- Customizable AI Solutions for Specific Industrial Needs: AI allows for the development of tailored solutions that meet specific industrial requirements. Companies can use AI to optimize specific processes, such as energy consumption or material usage, leading to more sustainable and cost-effective operations.

- AI-Driven Decision Making: AI tools are improving decision-making processes in industrial settings by providing insights derived from large datasets. These insights help in optimizing supply chains, improving quality control, and enhancing overall operational efficiency.

Recent Developments

- Siemens: In June 2023, Siemens partnered with Intrinsic, a robotics software company under Alphabet, to enhance AI-based robotics and automation technology. This collaboration aims to make industrial robotics more accessible, especially for small and medium-sized enterprises (SMEs). They are working on solutions to improve interoperability between automation and robotics systems, which could speed up the development of flexible AI-enabled work cells.

- Siemens & Microsoft: Siemens and Microsoft deepened their collaboration in 2023 to introduce the Siemens Industrial Copilot, a generative AI-powered assistant designed to improve human-machine collaboration in manufacturing. The integration of Siemens Teamcenter software with Microsoft Teams is expected to be generally available in December 2023, enabling better virtual collaboration across the product lifecycle.

- Honeywell: In July 2024, Honeywell released its Industrial AI Insights research, highlighting that AI adoption in industrial sectors is uncovering new use cases, with 94% of AI leaders planning to expand their AI utilization. The study also noted significant benefits such as improved efficiency, productivity, and enhanced cybersecurity.

- Siemens & AWS: Siemens also partnered with AWS to make generative AI more accessible by integrating AWS Bedrock with Siemens’ Mendix low-code platform. This move aims to support businesses in building and scaling AI applications across various industries.

Conclusion

In conclusion, the AI in Industrial Machinery market is at a transformative stage. As industries strive to enhance productivity and reduce operational costs, AI technologies are being integrated into various machinery and equipment to offer predictive maintenance, quality control, and optimized energy management. Also the advancements in machine learning and deep learning, which enable machines to perform complex tasks with greater accuracy and speed, further drives the market.

Despite challenges such as high initial investments and the need for skilled personnel, the potential for cost savings and improved productivity presents substantial opportunities. The convergence of IoT and AI further amplifies this potential, making AI integration an essential strategic move for industrial machinery companies aiming to remain competitive in a rapidly evolving technological landscape.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)