Table of Contents

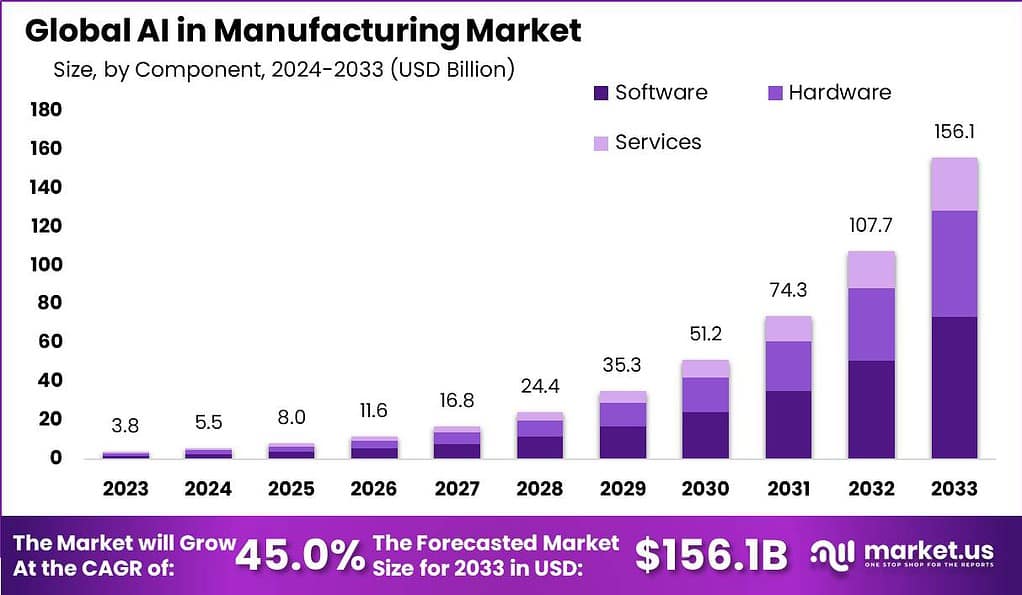

The global AI in Manufacturing market is poised for unprecedented growth, projected to boost from USD 3.8 billion in 2023 to around USD 156.1 billion by 2033, growing at a compound annual growth rate (CAGR) of 45% during the forecast period from 2024 to 2033. This surge is primarily fueled by the transformative impact of artificial intelligence (AI) technologies across the manufacturing sector, aimed at enhancing efficiency, reducing costs, and elevating quality control standards.

The adoption of AI in manufacturing is driven by meny factors, including the increasing demand for automation, predictive maintenance, and advanced quality control measures. AI technologies are particularly instrumental in streamlining complex processes through data-driven insights, making them invaluable for both large-scale and small to medium-sized manufacturers seeking to optimize product quality and manufacturing operations.

The transition towards Industry 4.0 plays a significant role in this growth, with smart manufacturing becoming increasingly reliant on connected components, smart sensors, and robotics automation. These technologies, alongside AI, IoT, and machine learning, are vital for enabling cognitive and autonomous solutions that enhance production processes, making industries more efficient and adaptive to customized demands.

One of the key applications of AI in manufacturing is predictive maintenance, which utilizes AI algorithms to predict equipment failures before they occur, thus preventing downtime and saving costs. Moreover, sectors such as metals & heavy machinery are anticipated to witness the highest growth rates, benefiting from AI’s capability to predict machine conditions and prevent unplanned downtime.

Regionally, the Asia Pacific market, led by industrial powerhouses such as China, Japan, and South Korea, is expected to grow at the highest CAGR. The region’s rapid industrialization, coupled with a high adoption rate of industrial robots that generate substantial data for AI algorithms, underpins this growth. Consequently, the AI in the manufacturing market in Asia Pacific is set to expand significantly, driven by smart robotics and increased productivity.

Key Takeaways

- The global AI in manufacturing market is projected to reach a substantial value of USD 156.1 billion by the year 2033, showing a robust CAGR of 45% during the forecast period from 2024 to 2033.

- AI in manufacturing involves using artificial intelligence technologies like machine learning, computer vision, and natural language processing to automate processes and improve efficiency in the manufacturing industry.

- By integrating AI technologies, manufacturers can enhance decision-making processes, reduce downtime, improve product quality, streamline supply chain operations, and ultimately achieve cost savings.

- A significant milestone has already been reached, with 35% of companies leveraging AI in their manufacturing processes.

- AI-driven decision-support systems have the potential to enhance manufacturing efficiency by up to 20%.

- AI is primarily implemented in maintenance and quality control functions within manufacturing processes.

- Approximately 29% of manufacturers use AI for maintenance purposes, resulting in potential cost reductions of up to 25% and 70% fewer breakdowns.

- AI-driven quality testing can lead to a 50% increase in factory productivity and achieve up to 90% accuracy in detecting defects.

- In 2023, the software segment held the largest market share in AI in manufacturing, capturing over 47.3%.

- North America led the AI in manufacturing market in 2023, with a dominant market share exceeding 35.1%, attributed to technological advancements and early adoption of AI technologies.

- The machine learning segment held a dominant market position in 2023, capturing more than a 42.9% share.

- The production planning segment held a dominant market position in 2023, capturing more than a 21.8% share.

- The automotive segment dominated the AI in manufacturing market in 2023, securing a substantial market share exceeding 22.5%.

- One of the primary drivers for the adoption of AI in manufacturing is the rising need to handle increasingly large and complex datasets.

- Reluctance among manufacturers to adopt AI-based technologies due to perceived high costs is a significant restraint.

- An opportunity lies in the application of AI-driven machine learning and NLP technologies for intelligent enterprise processes within the automotive industry.

- A key challenge is the shortage of skilled workforce, especially in developing countries.

- Siemens AG, IBM Corporation, Microsoft Corporation, Oracle Corporation, and Google LLC are among the top market leaders in AI in manufacturing.

AI in Manufacturing Statistics

- By 2035, AI could increase productivity in the manufacturing industry by 40% or more, as stated in a report by Accenture.

- Gartner predicts that by 2021, 20% of all manufacturers will deploy AI-based automation for large-scale standardization.

- Capgemini’s research reveals that currently, 44% of organizations in the manufacturing sector are implementing AI prototypes.

- IDC predicts that by 2021, 60% of manufacturing supply chains will use AI to detect 200% more disruptions.

- Tata Consultancy Services found that 28.5% of major manufacturers have invested in AI, with nearly 50% planning to do so by 2020.

- Statista reports that in 2021, 24% of manufacturing companies globally plan to test AI.

- Deloitte suggests that AI could lead to a productivity increase of as much as 40% by 2035 in the manufacturing industry.

- Gartner predicts that by 2022, 90% of corporate strategies will explicitly mention information and analytics as critical enterprise assets.

- Forbes notes that 29.7% of AI implementations in manufacturing are focused on maintaining machinery and production assets.

Use Cases Of AI in Manufacturing

Collaborative Robots (Cobots)

Cobots exemplify the synergy between human workers and robots, operating alongside humans to enhance productivity and safety without the need for extensive segregation or safety barriers. These AI-powered robots are instrumental in executing precision tasks such as assembly, quality control, and machine operation, thereby reducing operational costs and improving workplace safety.

- Cost Efficiency: Cobots are notably less expensive to deploy than traditional industrial robots, primarily because they do not require specialized infrastructure or safety installations.

- Adoption Rate: Leading automotive manufacturers like BMW and Ford have integrated cobots into their production lines for tasks including welding and quality inspections, showcasing a significant adoption trend.

- Productivity Enhancement: In sectors like consumer goods manufacturing, companies such as Procter & Gamble utilize cobots for product assembly and packaging, evidencing a direct impact on productivity and operational hygiene standards.

AI in Additive Manufacturing (3D Printing)

AI’s integration into additive manufacturing processes revolutionizes product design and quality control by optimizing material layering and detecting printing errors in real time.

- Innovation in Design: AI facilitates the creation of complex product designs, enhancing the performance and cost-effectiveness of manufactured goods. Footwear giants Adidas and Reebok, for instance, leverage AI in 3D printing to develop advanced shoe designs, signaling a broad potential for industry application.

- Process Optimization: AI-powered tools like Markforged’s Blacksmith enable real-time adjustments in the 3D printing process, ensuring that the final products closely match the original designs, thereby increasing the efficiency and reliability of additive manufacturing technologies.

Generative Design

Generative design algorithms represent a significant leap in product development, enabling designers to input specific parameters such as materials, cost constraints, and manufacturing methods, which the AI then uses to generate optimal designs.

- Acceleration of Product Development: This AI application drastically reduces the time and resources required for product design, by generating numerous design alternatives based on predefined criteria, thereby streamlining the innovation process.

- Cost and Resource Efficiency: AI’s capacity to conceptualize designs that are lighter, more durable, and less costly to produce promises substantial benefits across various industries, including automotive and aerospace, where efficiency and performance are paramount.

Predictive Maintenance

AI-driven predictive maintenance uses data analytics to foresee machinery failures before they occur, significantly reducing downtime and maintenance costs.

- Operational Continuity: By analyzing data from sensors and machine operations, AI algorithms predict maintenance needs, allowing for timely interventions that prevent costly breakdowns.

- Cost Reduction: Companies like Pepsi and Colgate employ AI technologies from startups such as Augury to anticipate and mitigate machinery issues, demonstrating AI’s role in reducing operational expenses through improved maintenance strategies.

The Lights-Out Factory

The concept of a “Lights-Out Factory” refers to a manufacturing facility that operates autonomously, without the need for human presence on-site. This AI-driven model signifies a leap towards fully automated production processes.

- Operational Efficiency: Japanese robotics manufacturer FANUC has been operating a lights-out factory since 2001, showcasing the ability to run uninterrupted for up to 30 days. This highlights a significant reduction in operational downtime and human resource dependency.

- Cost Reduction: Philips’ factory in the Netherlands, manufacturing electric razors with minimal human intervention, exemplifies cost efficiency, reducing labor costs by streamlining operations through AI.

- Sustainability: Automated factories are able to optimize energy usage more effectively than traditional factories, contributing to lower carbon footprints and enhanced sustainability.

AI in Additive Manufacturing Error Detection and Optimization

AI’s role in additive manufacturing (or 3D printing) has transcended beyond design, venturing into the realms of error detection and process optimization.

- Quality Assurance: AI-powered tools like Markforged’s Blacksmith software compare the 3D printed product against its digital twin to detect errors, automating quality assurance processes.

- Material Efficiency: By optimizing the 3D printing process, AI ensures material is used efficiently, reducing waste and costs associated with excess material use.

- Innovation Speed: Adidas and Reebok, leveraging AI in additive manufacturing, have accelerated the development of performance-enhancing footwear, demonstrating how AI can significantly shorten product development cycles.

Recent Developments

- Zeominds has developed ZeoAnalyzer, an AI-based software for predictive maintenance of industrial equipment. By analyzing data from IoT sensors, it identifies early signs of equipment failure, enabling timely repairs and reducing maintenance costs.

- Deevio, a German startup, offers AI-Box, a computer vision-based quality control solution. It uses AI-driven inspection workflows to automate visual inspection tasks on the production line, enhancing quality control efficiency.

- The Industrial Internet of Things (IIoT) continues to revolutionize manufacturing by providing real-time data and connectivity. Chilean startup Viga Lab develops IIoT platforms that connect companies to their machines, enabling remote monitoring and control of factory operations.

- Immersive Technology is gaining traction in manufacturing, with Keon Digital offering AR-based solutions for industrial training. This technology overlays digital content onto real-world equipment, improving training efficiency and safety.

- Big Data & Analytics play a crucial role in enhancing manufacturing processes. DatenBerg, for instance, utilizes big data and analytics to simplify decision-making in complex production processes, leading to improvements in efficiency and productivity.

Conclusion

Recent innovations highlight the diverse applications of AI in manufacturing, from Elementum’s advanced real-time supply chain monitoring to AI’s substantial contributions to overall equipment effectiveness (OEE) and quality control. These advancements not only optimize operations but also pave the way for more intelligent, flexible, and sustainable manufacturing practices. Furthermore, companies like Intel, Bridgestone, Danone, General Motors, and L’Oreal are leading examples of AI application in manufacturing, demonstrating significant improvements in product design, demand forecasting, and operational efficiency.

AI’s impact extends beyond conventional manufacturing processes, revolutionizing product research, design, and prototyping through AI-empowered product design and generative AI technologies. This fosters rapid innovation cycles and enables manufacturers to meet the increasing demands for customization and quality. Moreover, the integration of AI in robotics and automation is poised to redefine the manufacturing landscape, enhancing safety and productivity while reducing reliance on human labor for repetitive and hazardous tasks.

As the AI in Manufacturing market continues to evolve, it holds the promise of unlocking unprecedented levels of productivity, innovation, and competitiveness. The adoption of AI technologies is not just a trend but a strategic imperative for manufacturers aiming to thrive in the digital era.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)