Table of Contents

Introduction

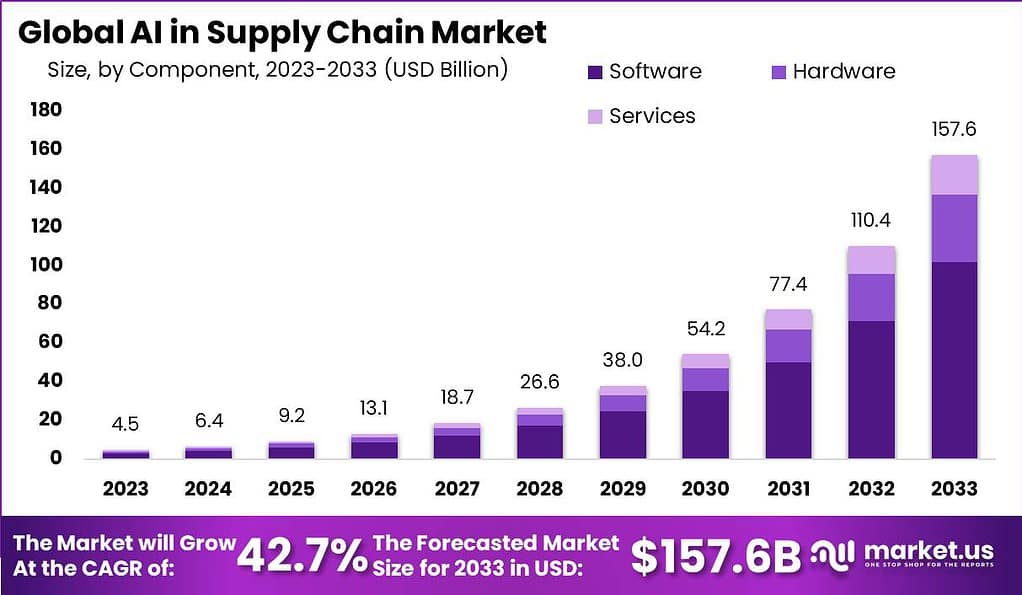

The AI in Supply Chain Market is projected to experience substantial growth, reaching a value of USD 157.6 billion by 2033, with an impressive Compound Annual Growth Rate (CAGR) of 42.7% from 2024 to 2033. This growth is fueled by the increasing integration of artificial intelligence (AI) technologies, such as machine learning, computer vision, and natural language processing, into various aspects of the supply chain.

AI in the supply chain is transforming how companies manage their operations, from procurement to delivery. Integrating AI helps optimize routes, predict demand, manage inventory, and enhance logistics efficiency. This adoption is fueled by AI’s ability to analyze vast amounts of data quickly and accurately, leading to better decision-making and reduced operational costs. The market for AI in supply chain is experiencing rapid growth, driven by the increasing need for automation and enhanced data analytics in logistics and supply chain management.

To learn more about this report – request a sample report PDF

However, the implementation of AI in the supply chain is not without challenges. Key issues include the high initial investment required for advanced AI tools and infrastructure, and the complexity of integrating AI systems with existing supply chain operations. Additionally, there is a significant skill gap, as employees must be trained to operate and maintain these sophisticated systems.

Data privacy and security concerns also pose major hurdles, as the use of AI involves handling sensitive information. Despite these challenges, the potential efficiencies and cost savings continue to drive the AI in supply chain market forward, with businesses increasingly recognizing the strategic value of AI technologies in gaining competitive advantages.

Key Takeaways

- The global AI in Supply Chain Market is expected to reach USD 157.6 billion by the end of 2033, with a remarkable Compound Annual Growth Rate (CAGR) of 42.7% over the forecast period from 2024 to 2033.

- In 2023, the software component held a dominant market position, capturing over 64.8% share. AI-driven software solutions are pivotal in integrating artificial intelligence into supply chain operations, automating processes, and enhancing data analytics.

- Machine learning technology dominated the market in 2023, with over 44% share. Its versatility and efficiency significantly improve precision and speed in supply chain management, particularly in areas like demand forecasting and inventory management.

- Demand Forecasting Segment Led the market in 2023, capturing more than 35.3% share. AI-driven demand forecasting enhances prediction accuracy, optimizing inventory levels, reducing costs, and improving responsiveness to market changes.

- The retail segment held a dominant market position in 2023, with over 24.1% share. Retailers extensively adopt AI technologies to streamline operations, optimize stock levels, and enhance customer experiences through personalized marketing.

- In 2023, North America held a dominant market position in the AI in supply chain market, capturing more than a 37.9% share

AI in Supply Chain Statistics

- Reduction in Prediction Errors: Implementing AI can decrease errors in future predictions by 20-50%. This improvement in forecasting accuracy can significantly reduce risks and optimize resource allocation.

- Decrease in Sales Losses: AI tools help in minimizing sales losses by up to 65%. This reduction is typically due to improved accuracy in demand forecasting and inventory management, leading to better availability of products.

- Reduction in Overstocking: Overstocking of inventories can be reduced by 20-50% through the use of AI. This is achieved by enhancing inventory management practices, which helps in maintaining optimal stock levels without overfilling warehouses.

- Lower Logistics Costs: Early adopters of AI in supply chain management have seen logistics costs reduce by 15%. This decrease is a result of more efficient route planning and automated logistics operations.

- Improved Inventory and Service Levels: Companies using AI report 35% higher inventory levels and 65% higher service levels. This indicates better stock management and an improved ability to meet customer demand promptly.

- Investment and Productivity Gains: Approximately $8.5 billion was invested in 2023 in AI-enabled automation and robotics within supply chains, leading to a 22% increase in warehouse productivity. This significant investment underscores the potential for AI to transform traditional warehousing operations.

- Enhanced Customer Service with AI Chatbots: According to a Capgemini report, 75% of supply chain leaders now use AI-powered chatbots for automating customer service and order management. This advancement has led to a 25% improvement in response times, showcasing AI’s role in enhancing customer interaction efficiency and satisfaction.

Emerging Trends

- Enhanced Visibility Beyond Tier 1: Supply chains are increasingly adopting technologies like control towers and digital twins to enhance visibility into deeper tiers of their supply network. This allows for greater transparency, risk management, and support for ESG (Environmental, Social, and Governance) goals.

- Low-code Development: There is a growing trend toward using low-code platforms which help in integrating disparate systems and speeding up digital transformation. This approach allows businesses to quickly adapt to new challenges and market conditions by enabling non-technical users to develop applications and automate processes.

- Sustainability and Scope 3 Emissions: Companies are placing a stronger focus on sustainability, especially in tracking and reducing Scope 3 emissions, which cover indirect emissions in the supply chain. The increasing legal mandates for emissions reporting in various countries are driving this trend.

- Advanced Digital Twins and Simulation: The use of digital twins to simulate supply chain operations for better planning and decision-making is becoming more common. These advanced models help in optimizing operations and enhancing predictive maintenance strategies.

- Multimodal AI Integration: AI technologies are being integrated in more complex and interactive ways. For instance, virtual agents are not just for customer service anymore but are also capable of performing tasks across various media, like interpreting visual data to interact with the environment.

Top 5 Use Cases for AI in Supply Chains

- Demand Forecasting and Inventory Optimization: AI-driven forecasting models are significantly improving demand planning and inventory management, minimizing costs associated with overstocking or understocking.

- Real-time Tracking and Monitoring: IoT devices and AI are being used for real-time tracking of goods throughout the supply chain, enhancing transparency and operational efficiency.

- Automated Warehouse Operations: Robotics and computer vision are playing key roles in automating warehouse tasks such as picking, packing, and sorting, thus improving efficiency and reducing manual labor.

- Transportation and Route Optimization: AI is being employed to optimize delivery routes and manage transportation networks more efficiently, reducing costs and environmental impact.

- Supply Chain Risk Management: AI tools are increasingly used to identify and manage risks in the supply chain, from predicting potential disruptions to suggesting mitigation strategies.

Major Challenges

- Complex Integration: Implementing AI across various functions of supply chain management remains complex. The challenge lies not just in deploying technology but ensuring it works harmoniously across different segments like procurement, logistics, and customer service.

- Data Quality and Management: Accurate and high-quality data are crucial for AI systems to function effectively. However, many companies struggle with collecting, cleaning, and organizing data which hampers the performance of AI-driven solutions.

- High Implementation Costs: The financial investment required to integrate AI into supply chains is substantial. Along with the initial setup, ongoing expenses in technology updates and training can be significant.

- Regulatory and Compliance Issues: With increasing regulations such as those addressing forced labor and sustainability, companies must ensure their AI systems comply with new and evolving laws.

- Resistance to Change: There is often a hesitance to adopt new technologies among staff. Trusting AI’s decision-making power and overcoming the cultural shift required for its acceptance pose significant challenges.

Market Opportunities

- Enhanced Decision Making: AI can process vast amounts of data to provide insights and foresight, enabling better decision-making and more precise predictions.

- Increased Efficiency and Reduced Costs: By automating routine tasks and optimizing logistics and inventory management, AI can significantly enhance operational efficiencies and reduce costs.

- Improved Customer Service: AI enables real-time tracking and predictive analytics for better demand forecasting and customer service, leading to increased customer satisfaction.

- Supply Chain Resilience: AI enhances the agility and resilience of supply chains, making them better equipped to handle disruptions and adapt to changes quickly.

- Sustainability and Compliance: AI can help companies monitor and ensure compliance with environmental and regulatory standards, which is increasingly important for corporate governance and sustainability initiatives.

Conclusion

The integration of AI into supply chain management offers promising opportunities to enhance operational efficiencies, improve decision-making, and ensure compliance with regulatory standards. However, the path is fraught with challenges, including the complexity of implementation, high costs, and the need for quality data. Overcoming these hurdles requires a strategic approach that aligns AI initiatives with business goals and involves stakeholders across the organization. As AI continues to evolve, its potential to transform supply chains grows, promising significant benefits for those who can navigate its challenges successfully.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)