Table of Contents

Introduction

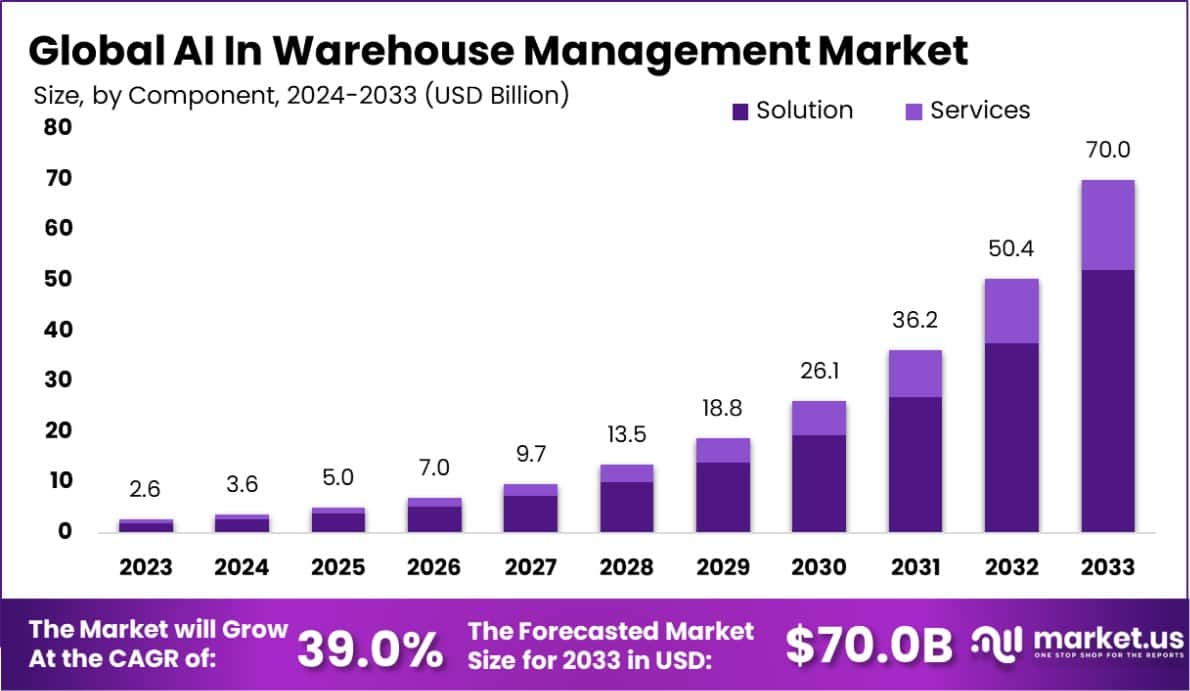

According to Market.us, The global AI in Warehouse Management Market is projected to reach approximately USD 70 billion by 2033, up from USD 2.6 billion in 2023, with a robust compound annual growth rate (CAGR) of 39.0% expected from 2024 to 2033.

AI in warehouse management refers to the use of artificial intelligence technologies to optimize and automate various warehouse operations. These technologies include machine learning, computer vision, robotics, and data analytics, which collectively enhance functions such as inventory management, order processing, sorting, and transportation scheduling. By integrating AI, warehouses can achieve higher efficiency, accuracy, and speed, reducing human error and operational costs while improving overall productivity.

The AI in Warehouse Management Market encompasses the sale and integration of AI technologies within logistics and storage facilities. This market is defined by the development, distribution, and implementation of AI solutions that cater to the specific needs of warehousing such as predictive analytics for inventory management, autonomous robots for material handling, and AI-driven systems for enhanced supply chain visibility. The market’s growth is closely tied to technological advancements and the increasing automation of the logistics sector.

The demand for AI in warehouse management is driven primarily by the growing need for efficient logistics operations, especially in industries where time and accuracy are critical factors, such as e-commerce, manufacturing, and retail. As these sectors expand, they require advanced solutions that can keep pace with increasing order volumes and customer expectations for fast delivery. AI provides the tools to manage complex warehouse operations more effectively, ensuring faster processing times and fewer errors, which in turn drives the demand for AI integrations in warehouses.

Several factors contribute to the growth of the AI in warehouse management market. The surge in e-commerce has been a significant driver, as online retailers require advanced warehousing solutions to handle large volumes of orders. Additionally, the push towards digital transformation across industries encourages companies to adopt AI to enhance efficiency and remain competitive. Technological advancements in AI and robotics also fuel market growth by continuously improving the capabilities and cost-effectiveness of AI solutions for warehouse management.

The market opportunities in AI for warehouse management are expansive. As AI technology advances, it opens up possibilities for even greater automation and efficiency. There is a particular opportunity in developing solutions that can be easily integrated with existing warehouse management systems, reducing the barrier to entry for many companies. Furthermore, as global markets increasingly shift towards just-in-time manufacturing and delivery models, there is a growing demand for AI systems that can predictively manage inventories and optimize logistics, providing ample growth avenues for this market.

Key Takeaways

- The global AI in Warehouse Management Market is projected to reach approximately USD 70 billion by 2033, up from USD 2.6 billion in 2023, with a robust CAGR of 39.0% during the forecast period from 2024 to 2033.

- In 2023, the Solution segment led the market in the Component category, accounting for over 74.5% of the market share.

- The Inventory Management segment dominated the market in the Application category in 2023, capturing more than 32.1% of the market share.

- The Retail & E-commerce segment was the leading end-use industry in 2023, holding over 34.0% of the market share.

- North America led the market in 2023, with a 38.8% share, generating USD 1.0 billion in revenue for the AI in Warehouse Management Market.

AI in Warehouse Management Statistics

- The Global Warehouse Automation Market is anticipated to expand significantly, with projections suggesting a growth from USD 20.8 Billion in 2023 to USD 91.0 Billion by 2033. This translates to a Compound Annual Growth Rate (CAGR) of 15.9% during the forecast period from 2024 to 2033.

- Currently, 87% of industry decision-makers are either in the process of or planning to expand their warehouses by 2024.

- It is observed that 80% of warehouse activities are outsourced, with the remaining 20% retained in-house as companies diversify geographically.

- There are over 18,736 private warehousing establishments. The average size of these facilities stands at 181,370 sq ft, with a trend toward larger warehouses increasing annually.

- About 70% of supply chain professionals view automation as having a positive impact on warehousing as of 2024.

- 79% of high-performing supply chain companies report revenue growth superior to the industry average.

- Up to 12% of companies are not cost-effective in their distribution strategies.

- By 2025, an estimated 4 million commercial warehouse robots are expected to be installed across more than 50,000 warehouses globally.

- In the U.S., 38% of companies plan to enhance inventory accuracy by adding more SKUs (scannable barcodes) and barcode scanners.

- Over 2.3 billion square feet of new warehousing space will be required by 2035 to meet expanding needs.

- 77% of organizations are actively considering automated warehouse systems and are planning to maximize data-driven performance.

- According to the MHI Annual Industry Report 2022, only 14% of respondents currently utilize AI technology. This figure is expected to grow by 73% over the next five years. Despite the low initial adoption rate, more than half believe AI will disrupt the industry and offer a competitive edge.

- Approximately 38% of logistics companies currently use AI technologies, potentially reducing operating costs by up to 50%.

- 74% of supply chain leaders are increasing their technology investments, with 90% planning to incorporate AI into their operations within the next few years, underscoring a robust commitment to using AI for a competitive advantage.

Emerging Trends

- Enhanced Safety and Efficiency with Cobots: Collaborative robots (cobots) equipped with AI and advanced sensors are increasingly being integrated into warehouse operations to work alongside human employees, enhancing safety and operational efficiency.

- Advanced Inventory Management with Drones: Drones are revolutionizing inventory management by providing faster and more accurate stock checks, accessing hard-to-reach areas, and offering comprehensive inventory data.

- Real-Time Data Utilization: The Internet of Things (IoT) is enabling real-time monitoring of warehouse operations, including tracking inventory levels, equipment performance, and environmental conditions to optimize operations.

- Sustainable Practices: As environmental concerns increase, more warehouses are adopting sustainable practices like using energy-efficient lighting, solar power, and sustainable packaging materials to reduce their carbon footprint.

- AI-Powered Predictive Analytics: Machine learning algorithms are being used for predictive maintenance and demand forecasting, significantly enhancing the ability to predict equipment failures and adjust inventory levels based on real-time demand forecasts.

Top Use Cases

- Automated Picking Systems: AI enhances the accuracy and speed of the picking process by directing robots and drones to retrieve items, reducing human error and increasing throughput.

- Load Optimization and Transportation Management: AI applications help optimize how goods are loaded and transported, reducing fuel costs and improving delivery times by analyzing and adjusting shipping logistics in real-time.

- Cold Chain Monitoring: AI-driven sensors continuously monitor temperature and humidity to ensure the integrity of perishable goods, alerting managers to any deviations that might compromise product quality.

- Automated Returns Processing: AI streamlines the returns process by rapidly categorizing returned items based on condition and reason for return, which improves inventory management and customer satisfaction.

- Space Optimization: AI-driven tools analyze warehouse layouts and recommend configurations that maximize storage efficiency and optimize floor space usage.

Benefits of AI Implementation in Warehouse Management

Implementing AI in warehouse management brings several benefits, including:

- Enhanced Efficiency and Accuracy: AI-driven systems optimize repetitive tasks, minimize human errors, and improve overall operational efficiency. By automating inventory management, order processing, and route optimization, warehouses can expedite workflows and improve precision in fulfilling orders.

- Real-time Data Insights and Predictive Analytics: AI enables real-time monitoring and data analysis, which supports better decision-making and operational responsiveness. Predictive analytics in AI help anticipate maintenance needs, market trends, and consumer behaviors, allowing for proactive inventory and supply chain management.

- Optimized Space Utilization: AI techniques analyze data such as inventory levels, product dimensions, and layout to suggest optimal storage configurations, thus improving space use and reducing retrieval times.

- Reduced Operational Costs: AI can streamline processes and reduce the need for manual labor, which helps decrease operational costs and increases overall profitability.

- Improved Safety and Maintenance: AI enhances safety by supporting risk assessments and predictive maintenance, which helps prevent accidents and reduces unplanned downtime by anticipating equipment failures before they occur.

Major Challenges

- Data Management Complexity: Integrating AI into warehouse operations requires high-quality, consistent data to function optimally. However, managing vast quantities of data, ensuring their accuracy, and handling inconsistencies pose significant challenges.

- High Initial Investment Costs: The implementation of AI technologies involves substantial initial investments for hardware and software. This financial burden can be a significant barrier, especially for smaller operations.

- Integration with Existing Systems: Integrating AI solutions with existing warehouse management systems without disrupting ongoing operations is a complex and challenging task.

- Skill Gap: There is a notable skills gap in the workforce concerning the deployment and maintenance of AI-driven technologies. Training staff or hiring new talent with the necessary technical expertise adds another layer of complexity and cost.

- Security and Privacy Concerns: With increased data collection and connectivity, warehouses face heightened risks related to data security and privacy. Protecting sensitive information against cyber threats is crucial yet challenging.

Top Opportunities

- Enhanced Operational Efficiency: AI enables significant improvements in operational efficiency through automation of routine tasks, optimizing inventory management, and streamlining the order fulfillment process.

- Improved Accuracy and Reduced Errors: AI-driven systems enhance the accuracy of inventory tracking and order fulfillment, significantly reducing errors and associated costs.

- Predictive Maintenance: Utilizing AI for predictive maintenance can forecast equipment failures before they occur, reducing downtime and maintenance costs. This proactive approach keeps warehouse operations running smoothly.

- Real-time Decision Making: AI facilitates real-time decision-making, offering warehouse managers insights into operational bottlenecks and workforce performance, which allows for swift adjustments to enhance productivity.

- Customer Satisfaction and Retention: By improving delivery accuracy and speed, AI-driven warehouses can enhance customer satisfaction and retention. AI also enables personalized customer service by predicting buying behaviors and optimizing stock levels to meet demand.

Recent Developments

- SAP SE: At Hannover Messe 2024, SAP unveiled significant AI-driven enhancements to its supply chain solutions. These include AI-driven insights for optimizing decision-making across the supply chain, AI-based anomaly detection in equipment, and enhanced field service operations. These advancements are expected to improve the efficiency and resilience of warehouse management systems, especially in handling large volumes of machine data.

- IBM Corporation: In August 2023, IBM expanded its collaboration with Microsoft by launching the IBM-Microsoft Experience Zone in Bangalore, India. This initiative aims to help clients explore generative AI-powered solutions for warehouse management and other business processes using Azure OpenAI Service.

- Oracle Corporation: In April 2023, Oracle introduced new AI and automation capabilities within its Oracle Fusion Cloud Applications Suite. These updates are designed to enhance supply chain planning, improve operational efficiency, and increase financial accuracy. Notably, Oracle’s new AI-powered lead time estimates in its Supply Chain Planning tool help optimize warehouse operations by providing more accurate predictions of lead times, which is crucial for efficient inventory management.

Future Trends and Innovations

The future of AI in warehouse management is likely to see several exciting trends and innovations:

- Autonomous Robots: The integration of AI with robotics is expected to grow, with robots performing more complex tasks such as navigating aisles and picking items autonomously.

- Advanced Predictive Analytics: AI will increasingly be used to provide more accurate demand forecasts using a combination of historical data and external factors like market trends.

- Enhanced Computer Vision: Developments in AI will improve the ability of systems to recognize and track inventory items accurately, supporting better inventory management.

- Machine Learning Optimizations: Continuous improvements in machine learning algorithms will further refine efficiency, from order processing to delivery optimization.

- Sustainability and Cost Efficiency: AI is expected to play a significant role in making warehouse operations more sustainable and cost-effective by optimizing energy use and reducing waste.

Conclusion

The AI in Warehouse Management Market is poised for continued growth despite facing challenges like high initial costs, the need for skilled workers, and data security concerns. The increasing demand for automation driven by the expanding e-commerce sector globally underscores the critical role of AI in enhancing logistics efficiency. As AI and machine learning technologies evolve, they offer new possibilities for optimizing warehouse operations, suggesting a robust future for this market. Businesses keen on maintaining competitiveness are likely to keep investing in AI solutions to meet rising consumer demands and improve operational efficiencies.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)