Table of Contents

Introduction

Automotive predictive maintenance refers to the use of data analysis tools and techniques to predict and prevent vehicle failures before they occur. This approach leverages real-time data from various sensors within the vehicle, combined with historical data and sophisticated analytics, to forecast vehicle repair needs. The goal is to maximize vehicle uptime, enhance safety, and reduce unexpected operational costs.

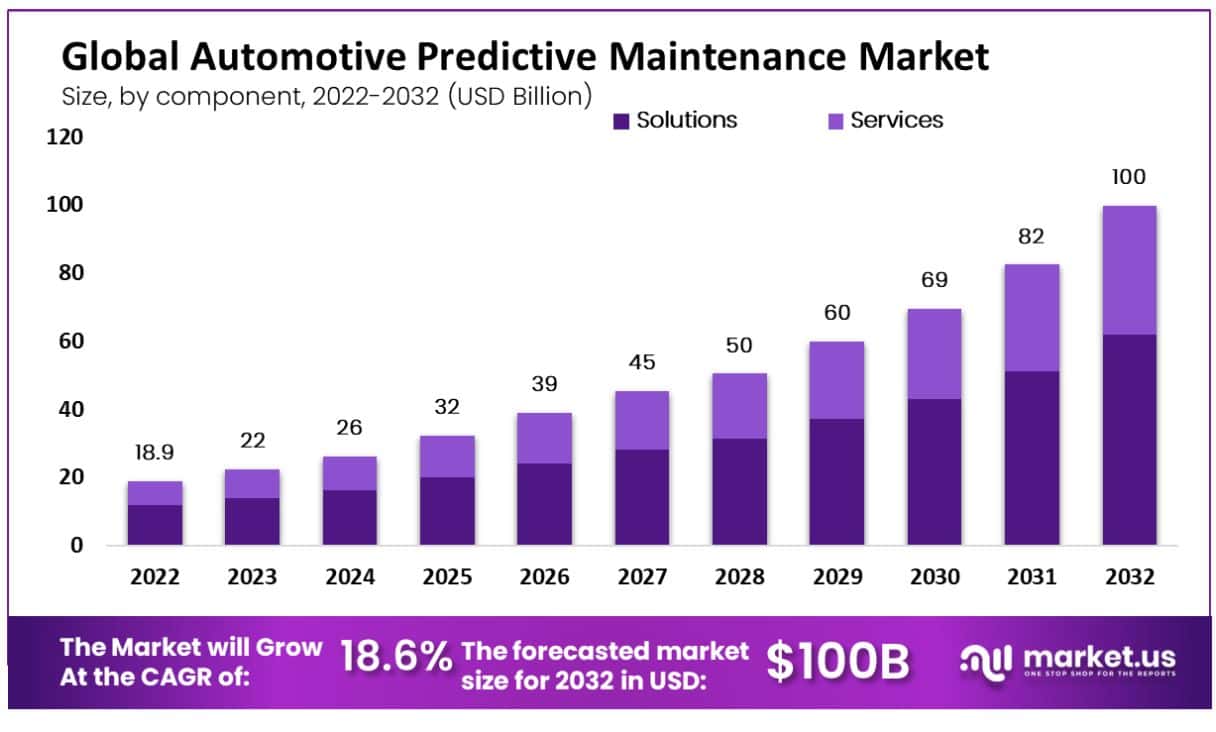

According to Market.us, The global automotive predictive maintenance market is set for considerable expansion, with projections indicating an escalation to approximately USD 100 Billion by 2032, rising from USD 22 billion in 2023. This growth trajectory suggests a strong compound annual growth rate (CAGR) of 18.6% during the forecast period from 2023 to 2032.

The automotive predictive maintenance market is rapidly growing, driven by the increasing demand for vehicle reliability and the extended lifespan of automotive components. This market focuses on utilizing advanced analytical tools and techniques to predict when a vehicle’s components might fail before they actually do. This proactive approach helps in reducing unexpected vehicle downtimes and costly repairs, enhancing overall efficiency.

One of the primary growth drivers for this market is the rising integration of Internet of Things (IoT) devices in vehicles. These devices collect real-time data from various vehicle components, enabling precise monitoring and early detection of potential issues. Additionally, the shift towards electric vehicles (EVs), which require meticulous maintenance of batteries and electric motors, further bolsters the market’s growth.

However, the market faces several challenges. The high initial investment in predictive maintenance technologies can be a significant barrier for small and medium-sized enterprises. Furthermore, the complexity of implementing these systems and the need for skilled personnel to analyze the data and make informed decisions are other critical challenges.

Despite these challenges, the market presents numerous opportunities. There is a growing demand for cloud-based solutions, which offer scalable and flexible data analytics capabilities. Additionally, the increasing awareness of the benefits of predictive maintenance, such as cost reduction and improved safety, continues to drive the market forward. As technology evolves, the integration of artificial intelligence and machine learning could further enhance predictive maintenance strategies, opening new avenues for growth in the automotive sector.

Key Takeaways

- In the segmentation by solutions, the Solutions segment took a prominent lead within the market in 2022, securing a dominant share of over 62%. This majority reflects the growing preference for integrated maintenance solutions that are pivotal in boosting vehicle reliability and minimizing operational downtime.

- Technological advancements are notably represented in the Internet of Things (IoT) segment, which held a significant market share of over 35% in 2022. The incorporation of IoT technologies is fundamental in facilitating real-time monitoring and predictive analytics within vehicle maintenance systems.

- Regarding vehicle types, the Passenger Cars segment was preeminent in 2022, representing more than 61% of the total market share. This dominance underscores the critical role of predictive maintenance in enhancing safety and efficiency for personal vehicle users.

- From a service perspective, the Oil Change segment illustrated its substantial market relevance by capturing over 22% share in 2022. This segment highlights the essential role of regular oil changes, which are increasingly being optimized through predictive scheduling and diagnostics.

- Geographically, North America maintained the lead in the automotive predictive maintenance market in 2022, commanding a robust share of over 43% and generating revenues of approximately USD 8.1 billion. This regional leadership is largely due to the advanced technological adoption and strict regulations pertaining to vehicle maintenance and safety prevalent in the region.

Automotive Predictive Maintenance Statistics

- The Predictive Maintenance Market is poised for significant expansion, projected to reach a value of approximately USD 107.3 Billion by 2033, with a robust Compound Annual Growth Rate (CAGR) of 28.5% from 2024 to 2033. This growth underscores the increasing recognition of predictive maintenance’s critical role in averting costly equipment failures.

- In an environment where median unplanned downtime can cost over $100,000 per hour, the capacity to predict and prevent large asset failures is increasingly indispensable. Predictive maintenance not only helps in significantly reducing downtime but also enhances asset longevity and operational efficiency.

- Financially, predictive maintenance presents compelling savings of 30-40% over reactive maintenance strategies, and 8-12% over traditional preventive maintenance approaches. Such savings are critical in justifying the investment in predictive technologies.

- Currently, 47% of global manufacturers have integrated predictive maintenance technologies into their operations, primarily to curtail operational expenses. This adoption rate signals substantial room for growth, as 53% of manufacturers have yet to deploy these technologies.

- Preventive maintenance remains prevalent, with 88% of manufacturing companies employing this strategy.

- However, only 52% utilize run-to-failure approaches, and a smaller fraction, 40%, implement preventive maintenance backed by analytics tools. Furthermore, 22% of companies engage in Reliability-Centred Maintenance (RCM), which leverages operational data analysis to enhance maintenance strategies and outcomes.

Emerging Trends

- Integration of AI and Machine Learning: Advanced algorithms are increasingly being utilized to analyze vast amounts of data, enhancing the accuracy of failure predictions and maintenance schedules.

- Use of Digital Twins: Virtual replicas of physical equipment are being used for continuous monitoring and analysis, enabling real-time insights and proactive maintenance strategies.

- Predictive Maintenance as a Service (PdMaaS): Cloud-based solutions are making advanced predictive maintenance tools accessible to a wider range of businesses, allowing them to benefit from predictive analytics without the need for in-house expertise.

- Immersive Technologies: Tools such as Extended Reality (XR) are transforming maintenance processes by improving the visualization and interaction with equipment, which aids in more precise inspections and troubleshooting.

- Increased Emphasis on Remaining Useful Life (RUL) Estimates: Predictive models are providing estimates on the remaining useful life of machinery, which is crucial for industries where maintenance is costly and requires advanced planning.

Top Use Cases

- Engine Performance Monitoring: Predictive maintenance is used to anticipate and address potential engine issues before they lead to failures, thereby improving vehicle reliability and performance.

- Exhaust System Checks: Regular predictive maintenance helps in monitoring and maintaining the health of the exhaust systems, which can prevent violations of emissions standards.

- Transmission Functionality: Ensuring the transmission system operates efficiently through predictive maintenance can significantly extend the lifespan of this critical component.

- Structural Stability: Through sensors and data analytics, predictive maintenance helps in monitoring the structural integrity of vehicles, thus ensuring safety and durability.

- Commercial Fleet Management: For commercial use, predictive maintenance is vital in managing fleet operations, optimizing uptime, and reducing costs by preventing unexpected vehicular downtimes.

Major Challenges

- High Initial Costs: The adoption of predictive maintenance solutions can be costly, particularly for small and medium-sized enterprises that might find the initial investment prohibitive.

- Technical Expertise Requirement: Implementing predictive maintenance solutions requires specific technical knowledge, which may not be readily available in all organizations.

- Data Quality and Security: The effectiveness of predictive maintenance heavily relies on the quality and security of data collected from various sources. Poor data quality or security breaches can significantly impact the system’s accuracy.

- Lack of Standardization: The automotive sector suffers from a lack of standardization, which can lead to compatibility issues across different preventive maintenance programs.

- Resistance to Change: There is often a significant resistance to adopting new technologies and processes within traditionally run organizations, which can slow down the implementation of predictive maintenance solutions.

Market Opportunities

- Cost Reduction: Early detection of issues through predictive maintenance allows automakers to reduce repair costs significantly.

- Increased Vehicle Uptime: By preventing unexpected breakdowns, companies can enhance the productivity of their fleets, leading to better fuel efficiency and reduced emissions.

- Competitive Advantage: Early adopters of predictive maintenance can gain a significant edge over competitors by improving vehicle reliability and performance, thus increasing customer satisfaction and market share.

- Data Utilization: The vast amount of data generated by predictive maintenance systems can be analyzed to derive insights about vehicle efficiency and maintenance needs.

- Technological Integration: The growing integration of IoT and the adoption of 5G technology enhance the capabilities of predictive maintenance systems, allowing for real-time monitoring and analysis, which is crucial for timely maintenance interventions.

Recent Developments

- Watsonx Platform: In May 2023, IBM launched the Watsonx platform, which includes Watsonx.ai for AI model development and Watsonx.data for optimized data management. These tools are expected to support various predictive maintenance applications by providing advanced AI capabilities and efficient data management

- Product Launch: In August 2023, Honeywell launched its Versatilis Transmitters solution, which enhances condition-based monitoring of rotating equipment across various industries. This innovation is part of Honeywell’s broader strategy to integrate advanced predictive maintenance solutions into automotive applications.

- Acquisition: In 2022, Siemens acquired Senseye, a company specializing in predictive maintenance and asset intelligence. This acquisition aims to broaden Siemens’ portfolio in innovative predictive maintenance solutions, enhancing their ability to predict and manage equipment health.

Conclusion

The automotive predictive maintenance market is poised for significant growth, driven by the increasing need for efficiency and vehicle uptime. However, the market faces challenges such as high initial costs and the need for specific technical expertise. The adoption of IoT and 5G technologies presents substantial opportunities for the industry, enabling real-time data analysis and the potential for substantial cost savings through optimized maintenance schedules. As the market evolves, the integration of advanced analytics and machine learning will likely become standard, offering companies the chance to not only anticipate maintenance needs but also enhance overall operational efficiency

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)