Table of Contents

Introduction

According to Autonomous Mobile Robots Statistics, Autonomous Mobile Robots (AMRs) are robotic systems that can move and navigate on their own, without the need for human control. They use sensors to understand their surroundings, create maps, and make decisions autonomously.

AMRs are applied in diverse fields, such as manufacturing, healthcare, retail, agriculture, and construction, bringing benefits like enhanced efficiency, safety, accuracy, and the potential for cost reduction.

However, introducing AMRs into operations requires an initial financial investment and smooth integration with existing systems. Despite these obstacles, continual technological progress points to a promising future for AMRs.

Editor’s Choice

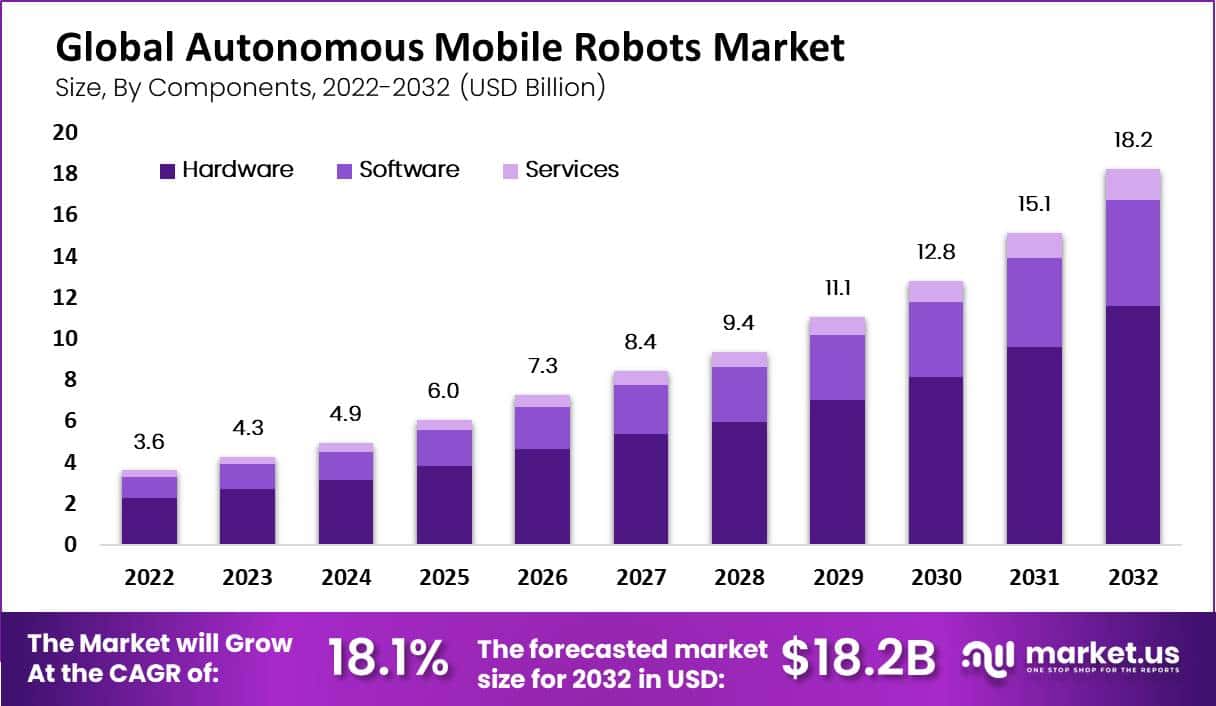

- The autonomous mobile robots market has been witnessing remarkable growth in recent years at a CAGR of 18.1%, with its revenue steadily increasing.

- In 2022, the market revenue stood at USD 3.6 billion, and it continued to expand significantly in the subsequent years.

- In 2022, the total market revenue stood at USD 3.6 billion, with hardware contributing USD 2.3 billion, software contributing USD 1.0 billion, and services accounting for USD 0.3 billion.

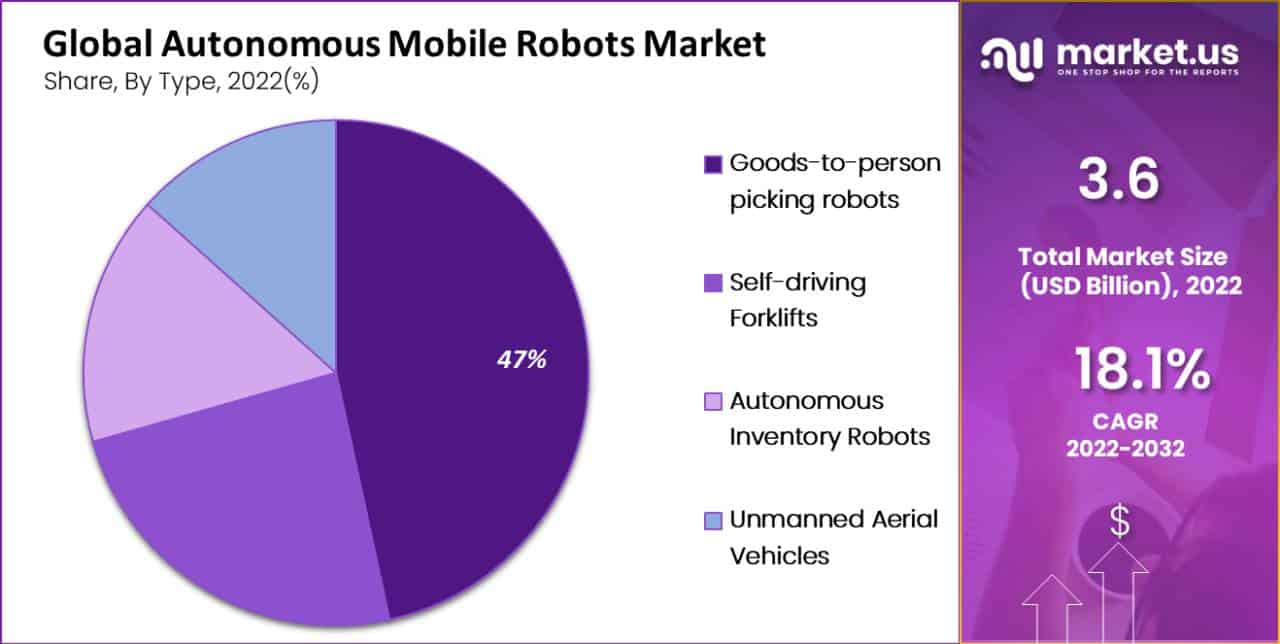

- According to the type of AMR, goods-to-person picking robots dominate with a significant market share of 47%.

- In 2018, the global shipment of autonomous mobile robots (AMRs) exceeded 20,000 units, more than doubling the figure from the previous year, according to a quarterly report by Interact Analysis.

- Despite robust demand in the supply chain and e-commerce sectors for AMRs, revenue growth was limited to 10%, with Dematic leading as the primary supplier.

- According to recent data, logistic robots occupy a substantial share, accounting for 31% of service robot utilization. These robots play a crucial role in optimizing and streamlining logistics operations.

Global Autonomous Mobile Robots Market Overview

Global Autonomous Mobile Robots Market Size

- The autonomous mobile robots market has been witnessing remarkable growth in recent years at a CAGR of 18.1%, with its revenue steadily increasing.

- In 2022, the market revenue stood at USD 3.6 billion, and it continued to expand significantly in the subsequent years.

- Looking further ahead, the autonomous mobile robots market is predicted to see even more substantial growth, with revenues projected to reach USD 15.1 billion in 2031 and a remarkable USD 18.2 billion in 2032.

Autonomous Mobile Robots Market Share – By Components

- The global autonomous mobile robots market’s growth can be analyzed by breaking down its components, including hardware, software, and services, along with the total market revenue of USD billion.

- In 2022, the total market revenue stood at USD 3.6 billion, with hardware contributing USD 2.3 billion, software contributing USD 1.0 billion, and services accounting for USD 0.3 billion.

- In 2024, the market further expands to reach USD 4.9 billion, with hardware, software, and services revenues of USD 3.1 billion, USD 1.4 billion, and USD 0.4 billion, respectively.

- This trend continues throughout the forecast period, with the market projected to achieve USD 18.2 billion in 2032.

- Hardware, software, and services are expected to contribute significantly, with revenues of USD 11.6 billion, USD 5.2 billion, and USD 1.5 billion, respectively.

Global Autonomous Mobile Robots Market Share – By Type

- The global autonomous mobile robots market is diversified across various types of robots, each with its share of the market.

- In this landscape, goods-to-person picking robots dominate with a significant market share of 47%. These robots are instrumental in optimizing warehouse operations by efficiently retrieving items for order fulfillment.

- Self-driving forklifts follow closely behind, commanding a 24% market share. These autonomous forklifts play a vital role in material handling and logistics.

- Autonomous inventory robots hold a substantial 16% market share, offering innovative solutions for inventory management and tracking.

- Lastly, unmanned aerial vehicles (UAVs) carve out a niche with a 13% market share, serving applications ranging from surveillance to delivery services.

Autonomous Mobile Robots Shipment Statistics

- In 2018, the global shipment of autonomous mobile robots (AMRs) exceeded 20,000 units, more than doubling the figure from the previous year, according to a quarterly report by Interact Analysis.

- This growth was witnessed across all regions, with Asia and notably China playing a significant role as primary drivers of this expansion.

- It’s worth noting that Amazon alone had already deployed over 200,000 AMRs by that time.

- Concurrently, the Robotic Industries Association (RIA) reported record-breaking robot shipments in North America, with 35,880 robots sent out in 2018, marking a 7% rise from the previous year.

- The RIA also highlighted a 41% surge in shipments to non-automotive companies, particularly in sectors like food, consumer goods, plastics, rubber, life sciences, and electronics.

Service Robots for Professional Use

- Service robots designed for professional use are making a significant impact across various application types.

- According to recent data, logistic robots occupy a substantial share, accounting for 31% of service robot utilization. These robots play a crucial role in optimizing and streamlining logistics operations.

- Additionally, robots designed for public environments hold a considerable share at 39%, contributing to enhanced efficiency and convenience in public spaces.

- Professional cleaning robots, with a usage rate of 41%, are revolutionizing the cleaning industry by offering automated and efficient solutions.

- Furthermore, medical robots, with a utilization rate of 30%, are increasingly being adopted in healthcare settings, assisting with various tasks and procedures.

Installations of Industrial Robots

- In 2020, the global installation of industrial robots saw varying degrees of activity across different industries.

- The electrical and electronics industry led the way with the highest number of installations, totaling 109,000 units.

- This reflects the sector’s continuous reliance on automation and robotics for manufacturing processes.

- The unspecified and other industries accounted for 86,000 installations, showing a broad application of industrial robots across diverse sectors.

- Meanwhile, the automotive industry, a long-time proponent of automation, recorded 80,000 installations, emphasizing its commitment to efficient production.

- Metal and machinery industries followed with 41,000 installations, further illustrating the widespread use of robotics in heavy manufacturing.

- Additionally, the plastic and chemical products industry saw 19,000 installations, while the food industry embraced automation with 12,000 new robot installations.

Trends in Industrial and Autonomous Robots

Business Operations

- Regarding expansion plans for the upcoming year, 79% of respondents expressed their intention to expand their operations, marking a 3% increase compared to the previous year.

- Capital expenditure (capex) remained robust, with an average projected expenditure of approximately $1.27 million for the next year, which closely resembled last year’s figures.

- Although the average respondent represented a smaller operation this year, 9% indicated plans to invest $10 million or more.

- The primary industry concern continued to be the difficulty in attracting and retaining a qualified hourly workforce, cited by 50% of respondents, although this figure slightly decreased from the previous year.

- Interestingly, the challenge of finding good supervisors experienced a notable increase, rising from 26% last year to 35% this year.

Operations and E-commerce

- The impact of e-commerce is clear in the shifts observed in both outbound and inbound operations among survey participants. In outbound operations, there was a 3% decrease in those exclusively handling split cases, while 22% now handle both cases and split cases, a significant increase from 13% the previous year.

- This means that a quarter of respondents are now engaged in shipping both case and split case items, or exclusively split case, up from 18% the prior year. Full pallet outbound operations remained constant at 10%.

- On the inbound side, there was a notable increase from 10% to 19% in operations dealing exclusively with full pallets.

Technology and Automation

- In the realm of materials handling systems, manual methods still play a significant role, with 72% of survey participants preferring manual picking, a slight decrease from the 76% reported last year.

- Conversely, automated replenishment methods saw a 7% uptick, and the use of automated storage and retrieval systems (ASRS) increased from 12% to 15% this year.

- Additionally, the adoption of robotic/articulating arms rose from 3% to 4%.

- Concerning specific picking technologies, paper-based approaches saw a 7% increase compared to the previous year.

- Notably, there was a significant doubling in the utilization of parts-to-person automation, surging from 7% to 14%. Voice-assisted solutions also experienced growth, increasing from 12% to 14% this year.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)