Table of Contents

Market Overview

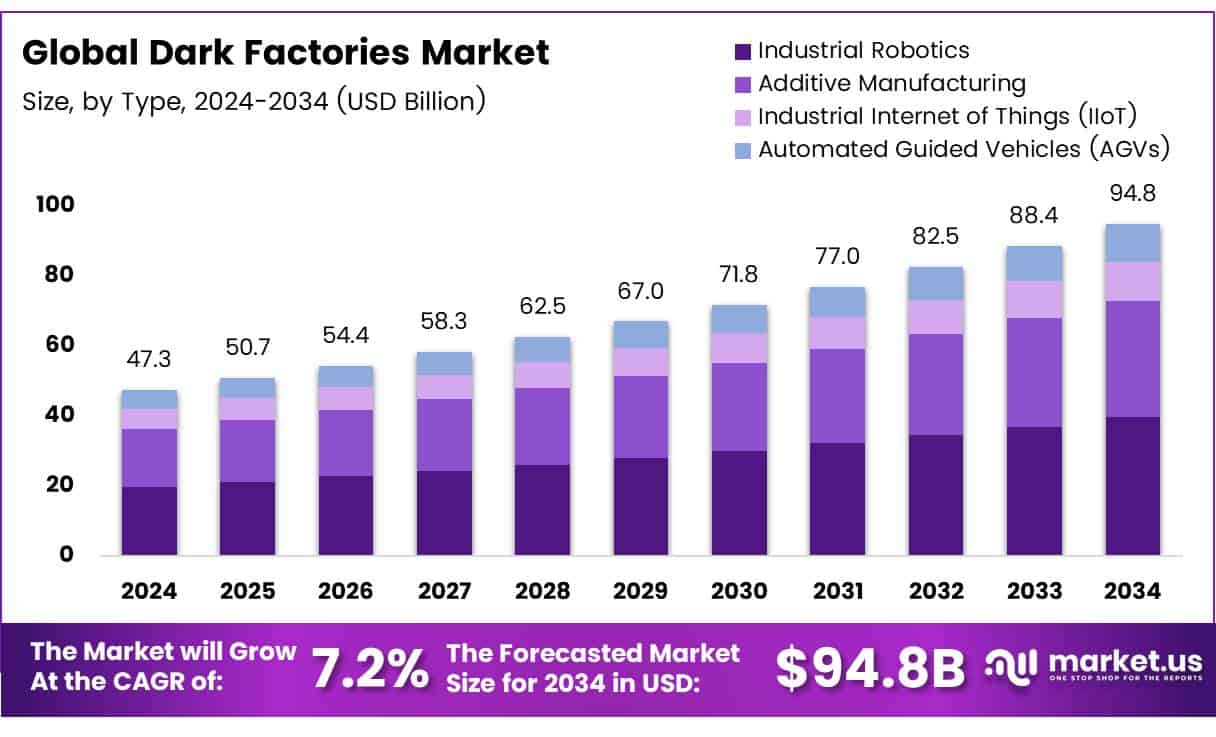

The Global Dark Factories Market size is expected to be worth around USD 94.8 Billion by 2034, from USD 47.3 Billion in 2024, growing at a CAGR of 7.2% during the forecast period.

The Dark Factories market also known as lights-out manufacturing is gaining serious momentum as global industries push for higher automation, efficiency, and cost control. Companies that adopt advanced automation technologies like robotic arms, AI-driven logistics, and sensor-based systems are seeing a productivity boost of up to 30%, according to McKinsey. This productivity surge is turning dark factories from a futuristic concept into a practical solution for manufacturers worldwide, especially in regions facing labor shortages and rising wage pressures.

The market opportunity is reinforced by the rise in industrial robot installations, growing at an average annual rate of 13.3% globally. In particular, China’s robot production soared by 51.5% year-on-year in April, signaling strong governmental and industrial support for automation technologies. Additionally, 91% of enterprises are now investing in IoT and smart manufacturing, indicating widespread acceptance and accelerated deployment of intelligent systems across sectors.

Governments are increasingly backing this transformation through incentives and digital infrastructure development. Smart factory initiatives and subsidies for Industry 4.0 technologies are being rolled out to enhance competitiveness. However, regulatory frameworks must evolve to address data privacy, worker displacement, and AI accountability critical to ensure sustainable growth in the dark factories space while maintaining economic and ethical balance.

Key Takeaways

- The Dark Factories Market is expected to grow from USD 47.3 Billion in 2024 to USD 94.8 Billion by 2034, at a CAGR of 7.2%.

- Industrial Robotics holds the largest share in the type segment with 45.2% in 2024, fueled by automation demand.

- Greenfield Projects lead the deployment segment with 54.1% share in 2024, driven by fully automated facility setups.

- The automotive sector dominates end-user adoption, accounting for 40.8% of the market in 2024, due to advanced robotics integration.

- Asia Pacific is the top regional market, holding a 44.8% share in 2024, supported by strong industrialization and automation investments.

Key Drivers

- Labor Shortages and High Labor Costs: Many developed and emerging economies are facing a skilled labor shortage. Dark factories offer a sustainable solution by minimizing human labor and automating repetitive tasks.

- Increased Demand for 24/7 Production: Businesses are seeking ways to run operations continuously without downtime. Dark factories can work round the clock, thereby enhancing output and profitability.

- Demand for Quality and Precision: Robotics and AI improve precision, reduce defects, and ensure consistent product quality, which is critical in sectors like electronics, automotive, and medical devices.

- Cost Optimization: Though the initial investment in robotics and automation is high, long-term gains from reduced labor, minimal wastage, and low error rates justify the cost.

- Health and Safety Concerns: In hazardous environments or during crises like pandemics, dark factories help ensure continuity without risking human lives.

Restraints

- High Initial Setup Costs: The cost of installing robotics, automation software, sensors, and smart systems is significantly high. Small and medium-sized enterprises (SMEs) may struggle to afford such investments.

- Lack of Skilled Workforce for Automation Management: Although these factories minimize human labor, they still require skilled personnel to monitor, maintain, and program machines.

- Cybersecurity Risks: As factories become more connected, they are also more vulnerable to cyber-attacks. Protecting sensitive manufacturing data is a major concern.

- Technological Complexity: Integrating and managing complex systems like AI, robotics, cloud computing, and IoT requires deep technical expertise and can be difficult to scale.

Opportunities

- Adoption in Emerging Markets: While dark factories are mostly concentrated in developed countries, emerging markets like India, Brazil, and Southeast Asia are beginning to explore automated manufacturing solutions, offering vast growth potential.

- Government Support for Smart Manufacturing: Many governments are launching initiatives and providing subsidies to promote Industry 4.0 and smart factory technologies. This encourages adoption across various sectors.

- Integration with Digital Twins and Predictive Maintenance: The integration of real-time monitoring, simulation tools, and predictive maintenance systems enhances factory uptime, optimizes production, and reduces operational costs.

- E-commerce and Consumer Electronics Boom: Industries with high production demand and short product lifecycles, such as electronics and e-commerce logistics, benefit significantly from automated production environments.

Market Segmentation

Type Analysis In 2024, Industrial Robotics led with 45.2% market share, driven by demand for automation and cost reduction. Additive Manufacturing is growing due to faster, waste-free production. IIoT improves real-time control and data sharing. AGVs automate material movement, making factories safer and more efficient.

Deployment Analysis Greenfield Projects held 54.1% share in 2024, as companies prefer building new smart factories with no legacy issues. Brownfield Projects still matter but face space and system limitations, slowing full automation.

End-User Analysis The automotive sector led with 40.8% share in 2024, using automation to boost output. Pharma adopted dark factories for precision. Aerospace used it for complex part making. Electronics relied on it for fine assembly. Other sectors are also joining the automation trend.

Regional Analysis

Asia Pacific leads the dark factories market in 2024 with a 44.8% share worth USD 20.8 billion. This growth is driven by rapid industrialization and big investments in automation in countries like China, Japan, and South Korea. Strong manufacturing presence and a push to cut labor costs are fueling demand for fully automated factories.

North America is growing fast, led by the U.S., where advanced AI and machine learning technologies are boosting automation. With strong tech companies and focus on innovation, the region is moving quickly toward fully automated manufacturing.

Europe is showing steady growth, supported by strict rules on worker safety and energy use. The region is focused on sustainable manufacturing and smart tech, which is helping dark factories expand.

Middle East & Africa

Dark factory adoption in the Middle East & Africa is just beginning. As these regions move away from oil and diversify their economies, they are slowly investing in automation and advanced technologies to modernize industries.

Latin America

Latin America is seeing gradual growth in dark factories. Countries like Brazil and Mexico are upgrading their factories with smart technologies to improve production efficiency and remain competitive in global manufacturing.

Competitive Landscape

- Technological innovation

- Strategic partnerships

- Mergers and acquisitions

- Long-term contracts with industrial clients

Future Outlook

The future of dark factories looks promising. With continuous improvements in AI, machine vision, robotics, and smart sensors, dark factories will become more intelligent, scalable, and cost-effective. Sustainability goals and ESG compliance will also drive green automation practices in these facilities.

As digital infrastructure becomes more accessible, dark factories are expected to become mainstream across various manufacturing sectors, transforming the future of industrial production.

Recent Developments

- In April 2025, 95% of manufacturing organizations reported difficulties in handling their data management and analytics initiatives, highlighting a critical gap in digital transformation strategies.

This struggle reflects the growing complexity of integrating data from automated systems, IoT devices, and supply chain operations. - In April 2025, three NYK Group companies NYK Shipmanagement, NYK Maritime Transport, and MTM Ship Management announced a strategic merger.

The move aims to streamline ship operations, enhance global competitiveness, and improve cost efficiency within the maritime sector.

Conclusion

The Dark Factories market is growing fast. It may hit USD 94.8 billion by 2034. Rising demand for automation drives growth. Governments and industries support adoption. High costs and tech issues remain barriers. AI and robotics fuel innovation. Emerging markets boost demand. Dark factories cut costs and raise efficiency. They are key to future manufacturing.