Table of Contents

Introduction

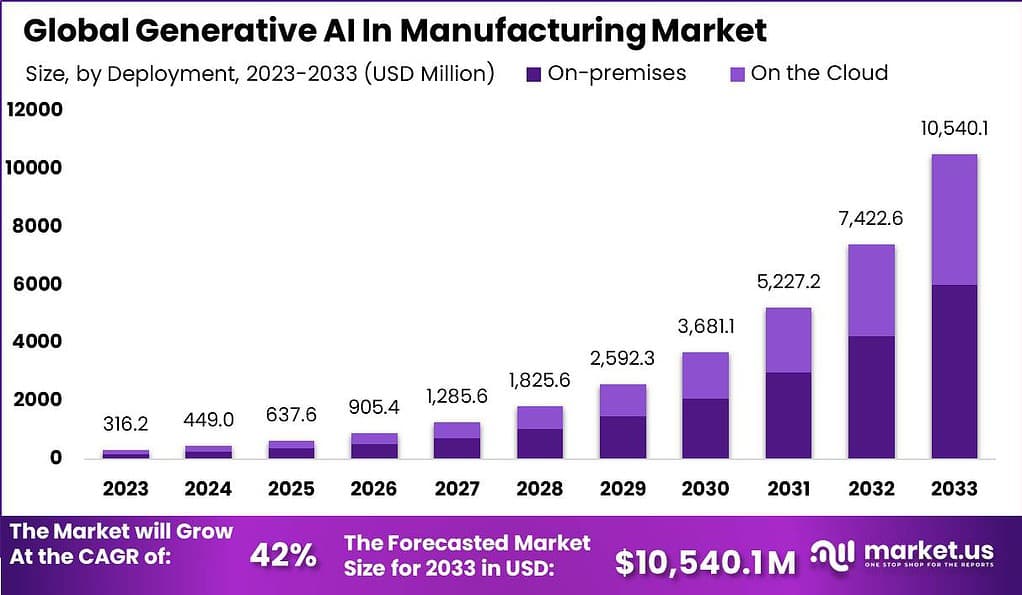

The Generative AI in Manufacturing Market is anticipated to reach a substantial value of USD 10,540.1 million by 2033, reflecting a robust Compound Annual Growth Rate (CAGR) of 42% during the forecast period from 2024 to 2033.

The Generative AI in Manufacturing Market is at the forefront of a technological revolution, transforming traditional manufacturing processes into highly efficient, innovative, and customizable operations. This market encapsulates the integration of artificial intelligence, particularly generative AI, into manufacturing to enhance design, production, and supply chain management. The growth of this market can be attributed to several factors, including the increasing demand for personalized products, the need for improving production efficiencies, and the reduction of manufacturing costs through automation. Additionally, generative AI’s ability to rapidly generate and evaluate multiple design solutions and process optimizations plays a critical role in accelerating product development and innovation.

However, the adoption of generative AI in manufacturing is not without challenges. Concerns regarding data privacy and security, the high initial investment for AI integration, and the need for skilled professionals to manage and operate AI systems pose significant hurdles. Moreover, the complexity of integrating AI into existing manufacturing systems and processes can also slow down adoption rates.

To learn more about this report – request a sample report PDF

Despite these challenges, the market leaders in the generative AI in manufacturing sector are paving the way for widespread adoption and innovation. Notable companies such as SAP SE, IBM Corporation, Microsoft Corporation, Alphabet Inc., Siemens AG, General Electric Company, Autodesk Inc., NVIDIA Corporation, Cisco Systems Inc., and Oracle Corporation are at the forefront of this transformation. These companies are not only contributing to the development of advanced generative AI solutions but are also instrumental in driving the market forward through strategic partnerships, research and development, and by offering comprehensive solutions that cater to the diverse needs of the manufacturing industry.

Key Takeaways

- Generative AI in Manufacturing Market is anticipated to reach a substantial value of USD 10,540.1 million by 2033, CAGR of 42%.

- Leading the market in 2022, the product design segment facilitated rapid design generation, reduced time-to-market, and enhanced product innovation, capturing over a 27.4% market share.

- By 2024, the adoption of generative AI for predictive maintenance is expected to decrease unexpected downtime by up to 30%, contributing significantly to productivity and cost savings.

- On-Premises Solutions held over a 56% market share in 2022 due to heightened control and security, especially favored by industries with sensitive data requirements like proprietary designs and data governance protocols.

- The automotive sector dominated the market in 2022 with over a 33.5% share, leveraging generative AI to drive innovation, efficiency, and sustainability in vehicle design, production, and supply chain management.

- North America emerged as the market leader, capturing more than a 47.6% share in 2022, propelled by robust technological infrastructure, significant investments in research and development (R&D), and a favorable regulatory environment supporting AI integration.

Generative AI In Manufacturing Statistics

- As per Deloitte’s findings, it enhances productivity by 25%, diminishes breakdowns by 70%, and reduces maintenance costs by 25%.

- Over 25% of manufacturing facilities worldwide will use generative AI to cut down on energy use by 2024, based on a survey by Capgemini. This is good for both saving money and helping the planet.

- By 2024, more than 40% of manufacturing companies are expected to use generative AI for designing products and making their processes better.

- More than 60% of new industrial robots will have generative AI features by the end of 2024, making them more flexible and smart.

- The market for generative AI is set to soar to about USD 255.8 Billion by 2033, starting from USD 13.5 Billion in 2023. That’s a yearly growth rate of 34.2% from 2024 to 2033.

- Currently, 44% of organizations are experimenting with generative AI, and 10% have fully integrated it into their operations.

- The AI in Manufacturing market size is expected to reach USD 156.1 Billion by 2033, up from USD 3.8 Billion in 2023, growing at a rate of 45% from 2024 to 2033.

- By 2024, it’s anticipated that over 60% of new products in manufacturing will be designed using generative AI.

- The use of generative AI for predictive maintenance is predicted to cut maintenance costs by up to 25% by 2024.

- By the end of 2024, more than 50% of new manufacturing execution systems (MES) will incorporate generative AI for real-time optimization.

Click here to check 200+ pages of in-depth market analysis reports on Generative AI In Manufacturing Market

Emerging Trends

- Hyper-Personalization and Conversational AI: Generative AI is enhancing personalization and interaction capabilities, leading to more intuitive user experiences and increased efficiencies in manufacturing processes.

- Advances in Scientific Research and Material Development: Large language models are being leveraged for the development of novel materials and biologics, contributing to advancements in energy-efficient products and processes.

- Generative Design in Engineering: This trend sees AI assisting in the creation of innovative product designs that optimize for various factors, including cost, materials, and manufacturing constraints, significantly speeding up the design process.

- Optimization of Production and Supply Chains: AI’s ability to analyze vast datasets is being used to improve safety, production efficiency, and supply chain resilience, offering manufacturers the tools to better navigate disruptions and enhance operational efficiency.

Use Cases

- Product Engineering: Generative AI aids in exploring efficient design solutions quickly, reducing engineering design and production time.

- Improving Safety and Quality Control: By analyzing large datasets, generative AI can identify patterns that help improve product safety and quality.

- Production Optimization: Generative AI is used to predict and mitigate downtime in production lines, optimizing overall equipment effectiveness.

- Supply Chain Management: AI applications provide increased visibility and predictive analytics for supply chain operations, enhancing decision-making and reducing costs.

8 Benefits Of Generative AI in Manufacturing

Generative AI is revolutionizing the manufacturing industry by offering a myriad of benefits that enhance operational efficiency, innovation, and competitiveness. Here are eight key benefits of employing generative AI in manufacturing:

- Enhanced Product Design: Generative AI algorithms can generate numerous design alternatives based on specified criteria, enabling engineers to explore a wider array of design options and optimize products for performance, aesthetics, or sustainability goals.

- Faster Time-to-Market: By automating part of the design process and optimizing manufacturing workflows, generative AI helps reduce the time from concept to market. This acceleration allows companies to respond more swiftly to market demands and emerging trends.

- Increased Customization and Personalization: Generative AI enables manufacturers to offer products tailored to individual customer preferences without significantly increasing production costs or complexity. This level of customization enhances customer satisfaction and loyalty.

- Improved Efficiency and Cost Reduction: Through predictive maintenance and optimized production processes, generative AI can significantly increase operational efficiency, thereby reducing waste and lowering manufacturing costs.

- Supply Chain Optimization: Generative AI aids in the forecasting of supply and demand, identifying bottlenecks, and suggesting optimal supply chain configurations. This results in reduced lead times, lower inventory costs, and improved delivery performance.

- Quality Control and Defect Detection: By analyzing data from manufacturing processes and quality control points, generative AI can identify patterns that may lead to defects, enabling preventative measures to be taken before issues arise, thus enhancing product quality.

- Sustainability and Eco-Friendly Manufacturing: Generative AI supports the development of products and processes that are not only efficient but also environmentally friendly. It helps in designing products that use less material and energy, contributing to a reduced carbon footprint.

- Worker Safety and Ergonomics: By analyzing workplace data, generative AI can suggest improvements in manufacturing processes and plant layout that enhance worker safety and ergonomics, leading to a healthier and more productive workforce.

Major Challenges

- Data Privacy and Security: Ensuring the privacy and security of data as generative AI models require access to vast amounts of data.

- Integration with Existing Systems: The challenge of integrating generative AI technologies into existing manufacturing systems and workflows.

- Skill Gap: There’s a need for skilled personnel to develop, manage, and interpret generative AI models and their outputs.

- Reliability and Trust: Establishing the reliability of AI-generated outcomes and building trust among users in the manufacturing industry.

Market Opportunity

The Generative AI in Manufacturing Market presents several opportunities that signal strong growth potential in the coming years. These opportunities are derived from the transformative capabilities of generative AI technologies across various facets of manufacturing, including design, production, supply chain management, and customer engagement. Here are some key market opportunities identified:

- Integration into Design Workflows: Generative AI’s integration into design workflows enables engineers and designers to optimize product designs more efficiently. This integration enhances traditional design processes with AI algorithms, facilitating more innovative solutions and faster time-to-market for new products.

- Rise of Cloud-Based Platforms: There’s a significant shift towards cloud-based generative AI platforms, offering scalable and accessible solutions for manufacturers. These platforms allow companies to leverage generative AI without the need for extensive hardware investments, making advanced design and optimization tools more accessible.

- Focus on Sustainable and Eco-Friendly Designs: With an increasing emphasis on sustainability, generative AI offers opportunities to design more eco-friendly products. Manufacturers can use AI to develop products that meet environmental standards while maintaining or enhancing performance and aesthetic appeal.

- Human-Machine Collaboration: Generative AI fosters a collaborative environment where human designers work alongside AI algorithms. This collaboration spurs innovation in design, leading to unique and customer-centric products.

- Supply Chain Optimization: By analyzing large datasets, generative AI can optimize supply chain processes, improving agility, reducing lead times, and enhancing efficiency. This optimization is crucial for adapting to market changes and meeting customer demands swiftly.

Top 10 Vendors

- SAP SE: A global software corporation based in Germany, SAP specializes in enterprise software to manage business operations and customer relations. SAP is increasingly incorporating AI into its solutions to enhance business processes and manufacturing operations.

- IBM Corporation: An American multinational technology company, IBM is at the forefront of AI research and its application in various industries, including manufacturing. IBM’s Watson is a notable example of AI being used to analyze data, improve decision-making, and optimize operations.

- Microsoft Corporation: Known for its software, services, devices, and solutions, Microsoft is also deeply involved in AI through cloud computing services like Azure, offering AI capabilities to help businesses innovate and improve efficiency in manufacturing.

- Alphabet Inc.: The parent company of Google, Alphabet is pioneering in AI and machine learning technologies with applications ranging from data analytics to autonomous driving. Alphabet’s AI research and tools are instrumental in pushing the boundaries of what’s possible in manufacturing and other sectors.

- Siemens AG: A German multinational conglomerate, Siemens is heavily invested in digitalization and automation technologies for the manufacturing industry. Its use of AI enhances everything from product design to production processes, improving efficiency and innovation.

- General Electric Company: GE is an American multinational conglomerate with a focus on renewable energy, aviation, healthcare, and more. GE leverages AI in its manufacturing processes to optimize performance, maintenance, and operational efficiency.

- Autodesk Inc.: Specializing in software for architecture, engineering, construction, manufacturing, media, and entertainment, Autodesk integrates AI into its tools to revolutionize design and manufacturing processes, enabling greater creativity and efficiency.

- NVIDIA Corporation: Best known for its graphics processors, NVIDIA also drives AI computing innovation. NVIDIA’s GPUs and AI platforms are critical for AI research and applications in various fields, including robotic manufacturing and autonomous machines.

- Cisco Systems Inc.: As a leader in IT and networking, Cisco incorporates AI into its solutions to improve security, networking, and the Internet of Things (IoT), directly impacting how manufacturing industries connect and secure their operations.

- Oracle Corporation: Specializing in database software and technology, cloud engineered systems, and enterprise software products, Oracle offers AI-powered cloud applications and data analytics that enhance business insights, decision-making, and process automation in manufacturing.

Recent Developments

- Siemens AG (October 2023): Launched Siemens NX Generative Design software, utilizing generative AI to automate product design processes.

- Autodesk Inc. (July 2023): Announced integration of generative AI into its Fusion 360 platform, allowing for AI-powered generative design workflows.

- NVIDIA Corporation (May 2023): Unveiled its NVIDIA Omniverse Generative AI Toolkit, designed for developers to build custom generative AI applications for manufacturing tasks.

Conclusion

In conclusion, The adoption of Generative AI in the manufacturing sector marks a pivotal shift towards more innovative, efficient, and responsive industrial operations. As highlighted through various insights, this transformative technology stands at the forefront of driving personalized product development, optimizing design processes, enhancing production efficiency, and streamlining supply chain management. The emerging trends, use cases, challenges, and market opportunities associated with Generative AI illustrate its potential to revolutionize the manufacturing landscape by offering solutions that were previously unattainable.