Table of Contents

Introduction

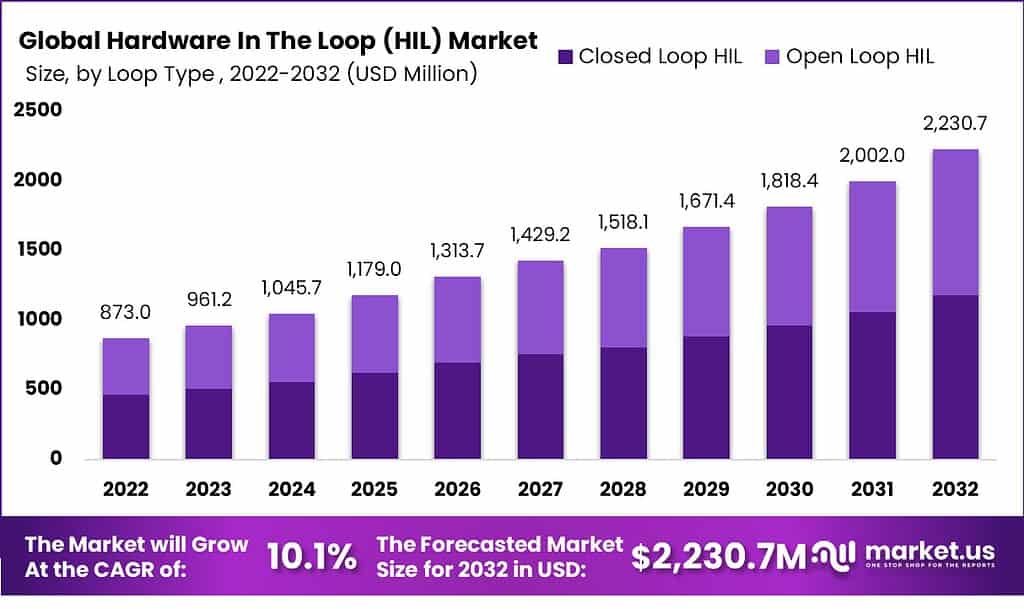

The Hardware in The Loop (HIL) Market is projected to achieve a CAGR of 10.1%, reaching a value of USD 2,230.7 million by 2032, up from USD 961.2 million in 2023.

Hardware in the Loop (HIL) is a technique used in the development and testing of complex real-time embedded systems. HIL simulation provides an effective platform by connecting the physical components of a system to a virtual environment that simulates the system’s operating conditions. This approach allows for rigorous testing of the hardware components, including their control algorithms, responses, and interactions with simulated external factors, without the need for a complete physical prototype. The primary benefit of HIL testing is the ability to identify and rectify errors at an early stage of development, significantly reducing the time and cost associated with physical testing.

The market for Hardware in the Loop (HIL) has been witnessing growth due to the increasing demand for these systems in various industries such as automotive, aerospace, defense, energy, and electronics. The need for reduced development times and enhanced product quality, alongside the rising complexity of electronic and mechanical systems, drives the adoption of HIL technology. Automotive and aerospace sectors, in particular, have been leading adopters, utilizing HIL systems to advance the development of electric vehicles, autonomous driving technologies, and more efficient aircraft systems. The market’s expansion is further supported by continuous advancements in simulation technologies, offering more realistic and comprehensive testing environments.

HIL testing offers several benefits. Firstly, it reduces development time and costs by enabling early detection and resolution of potential issues in the design phase. By simulating real-world conditions, engineers can identify and address system-level problems before physical prototypes are built, saving time and resources.

Secondly, HIL testing provides a controlled and repeatable environment for testing complex systems. Engineers can simulate various scenarios, including extreme conditions or rare events, that may be difficult or impractical to recreate in real-world testing. This enhances the overall robustness and reliability of the system.

Key Takeaways

- Hardware in The Loop (HIL) Market Size Recorded Sales of USD 961.2.0 Mn in 2023. The Market experienced a CAGR of 10.1% year-on-year growth. It is anticipated to achieve revenues of USD 2,230.7 Mn by 2032

- Closed-loop HIL holds the majority share at 53.0%, offering superior reliability and stability in error detection and correction, while open-loop HIL is gaining traction for its simpler design and cost-effectiveness.

- The automotive sector dominates with a 54.5% market share, driven by increased integration of HIL technology for enhanced Electronic Control Units (ECUs) and compliance with industry regulations. Aerospace and defense segments also show significant growth.

- Technological advancements in autonomous and electric vehicles are propelling market growth, with automotive manufacturers investing heavily in ADAS and autonomous driving technologies.

- Implementing HIL methodology is complex and costly due to the intricate nature of mathematical models and the need for robust hardware capable of processing substantial data volumes.

- HIL testing is expanding into new sectors such as power electronics and industrial robotics to meet industry safety standards and validate complex controllers.

- The latest trend involves the development of the 4th generation HIL framework, catering to advanced applications in motor drive systems, power electronics, and automotive testing.

- North America leads with 35.6% market share, driven by robust automotive and aerospace sectors, followed by Europe. The US and Canada are significant contributors, with Europe benefiting from ICT sector amplification.

- Major players include DSpace GmbH, National Instruments, Vector Informatik, ETAS, Ipg Automotive GmbH, among others, focusing on product launches and strategic partnerships to maintain competitiveness and drive market growth.

- HIL testing verifies and validates the performance of real-time embedded systems by connecting them to a simulated environment, ensuring their effectiveness and reliability.

- The automotive industry extensively uses HIL testing to validate electronic control units (ECUs) for various vehicle systems, enhancing safety and performance.

- By reducing the need for expensive prototypes and field testing, HIL simulation saves significant time and costs in product development.

- Advanced driver-assistance systems (ADAS) and autonomous driving technologies rely heavily on HIL testing to ensure their safety and reliability.

- In the aerospace industry, HIL is crucial for testing flight control systems, avionics, and other critical components in a safe, simulated environment.

- HIL testing validates software and hardware components of industrial automation systems, including programmable logic controllers (PLCs), ensuring their proper function and integration.

- Renewable energy systems, such as wind turbines and solar inverters, undergo HIL testing to guarantee their operation under various environmental conditions.

- HIL simulation can replicate scenarios too dangerous or costly to test in real life, like power grid faults or engine failures, ensuring system robustness.

- Modern HIL systems often utilize field-programmable gate arrays (FPGAs) and real-time operating systems for high-speed, deterministic simulation.

- Aerospace companies, including NASA and Boeing, use HIL testing for validating space systems and spacecraft components, ensuring mission success.

- The defense industry employs HIL testing to verify and validate weapon systems, radar systems, and other military equipment for reliability and effectiveness.

- Automotive OEMs such as Ford, Toyota, and Volkswagen have dedicated HIL testing facilities to ensure vehicle components and systems meet strict quality standards.

- HIL testing simulates environmental factors like temperature, vibration, and electromagnetic interference for comprehensive system testing.

- Industry standards and regulations, such as ISO 26262 for automotive functional safety, mandate the use of HIL testing.

- HIL simulation integrates with other testing methods like software-in-the-loop (SIL) and model-in-the-loop (MIL) for thorough validation processes.

- The rise of electric and hybrid vehicles has spurred demand for HIL testing of battery management systems and power electronics.

Don’t wait another moment – complete the necessary information and unlock a wealth of knowledge. Seize this chance to make informed decisions and drive your success to new heights!

Emerging Trends

- Integration with Virtual Reality (VR): There’s a growing trend of combining HIL testing with VR technologies. This allows engineers and developers to immerse themselves in the simulation, providing a more intuitive understanding of how systems behave in real-world scenarios.

- Cloud-Based Solutions: Cloud technology is making HIL simulations more accessible and collaborative. Teams can now work together from anywhere in the world, sharing resources and results in real-time, which speeds up the development process.

- Increased Use of Artificial Intelligence (AI): AI is being integrated into HIL systems to automate testing processes and analyze results. This leads to smarter, faster testing cycles and the ability to predict system behaviors under various conditions.

- Greater Focus on Cybersecurity: As systems become more connected, cybersecurity in HIL testing is gaining importance. This involves simulating cyber attacks on embedded systems to ensure they can withstand real-world threats.

- Expansion into New Industries: While automotive and aerospace have traditionally dominated HIL testing, industries like healthcare, consumer electronics, and renewable energy are increasingly adopting HIL technologies for their development processes.

- Adoption of Agile Methodologies: Agile development practices are being applied to HIL testing, allowing for more flexible and iterative design cycles. This helps teams adapt quickly to changes and integrate feedback earlier in the development process.

- Customization and Flexibility: There’s a shift towards more customizable HIL platforms that can easily adapt to specific project requirements. This flexibility allows for a wider range of testing scenarios and system configurations.

Major Challenges

- Complexity of System Integration: HIL testing involves integrating complex hardware components, such as sensors, actuators, and controllers, with simulation models. Ensuring seamless integration and synchronization between physical and virtual components can be challenging, requiring expertise in various domains.

- Cost of Hardware: HIL testing requires high-performance hardware setups, including real-time simulators and control units, which can be expensive. The cost of acquiring and maintaining these hardware systems poses a significant challenge, particularly for small and medium-sized enterprises (SMEs) with limited budgets.

- Availability of Realistic Simulation Models: Accurate and realistic simulation models are crucial for effective HIL testing. However, developing and acquiring such models for different systems and scenarios can be time-consuming and costly. The availability of reliable and up-to-date simulation models is a challenge that needs to be addressed.

- Scalability and Flexibility: HIL systems need to accommodate a wide range of testing scenarios, from simple to complex, and should be able to scale according to the requirements of different applications. Designing flexible and scalable HIL setups that can adapt to evolving testing needs is a challenge, as it requires careful consideration of hardware and software architectures.

- Data Synchronization and Latency: HIL testing involves real-time interaction between physical and virtual components. Achieving accurate data synchronization and minimizing latency between the hardware and simulation models is a critical challenge. Any inconsistencies or delays in data exchange can affect the reliability and validity of the test results.

- Standardization and Interoperability: With multiple vendors offering HIL solutions, there is a lack of standardized interfaces and protocols, making interoperability a challenge. Integrating components from different vendors and ensuring seamless communication between them can be complex and time-consuming.

- Security and Intellectual Property Protection: HIL systems often involve testing sensitive and proprietary technologies. Ensuring the security of intellectual property and protecting against unauthorized access or data breaches is a significant challenge. Robust security measures need to be implemented to safeguard valuable information during HIL testing.

- Training and Expertise: HIL testing requires specialized knowledge and skills in areas such as simulation modeling, system integration, and test automation. Developing a skilled workforce and providing adequate training opportunities for engineers and technicians to effectively operate and maintain HIL systems is a challenge that the industry needs to address.

Recent Developments

- dSPACE at CES 2024 Announcement (December 2023): dSPACE previewed its latest solutions for data-driven development, simulation, and validation of electric and self-driving cars at CES 2024. The company showcased new HIL systems for full-power testing of inverters and control electronics, a smart charging solution for electric vehicles, and advanced simulation technologies for autonomous driving.

- Emerson’s Acquisition of National Instruments (NI): On April 12, 2023, Emerson announced its plan to acquire National Instruments for ~$60 per share in cash, valuing the transaction at approximately ~$8.2 billion. This strategic move aims to enhance Emerson’s automation capabilities and expand its presence in high-growth discrete end markets.

- NI Connect 2024 Event Announcement: NI Connect is scheduled to take place from May 20 to May 22, 2024, in Austin, Texas. The event will highlight how leading companies are leveraging their test organizations as a strategic differentiator to drive innovation and performance.

Conclusion

In conclusion, Hardware in the Loop (HIL) is a testing technique that connects physical hardware components to a simulation environment for comprehensive testing and validation. The HIL market has experienced growth due to the increasing complexity of modern systems and the need for thorough testing. HIL testing offers benefits such as reduced development time and costs, controlled and repeatable testing environments, and comprehensive evaluation of system interactions. As technology continues to advance, the HIL market is expected to evolve, providing more advanced and efficient solutions for testing complex systems.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)