Table of Contents

Introduction

According to Heat Exchanger Statistics, Heat exchangers are crucial in various industries, efficiently transferring heat between fluids without direct contact. They have heating, cooling, and temperature control applications, including HVAC, power generation, and chemical processing. These devices allow heat to flow through solid walls or plates, separating hot and cold fluids.

Common types include shell, tube, Plate, and finned tube heat exchangers. Regular maintenance is essential to ensure their efficiency, as factors like fouling and corrosion can affect their performance. In summary, heat exchangers play a vital role in diverse industrial processes, making understanding their basics essential for professionals in relevant fields.

Editor’s Choice

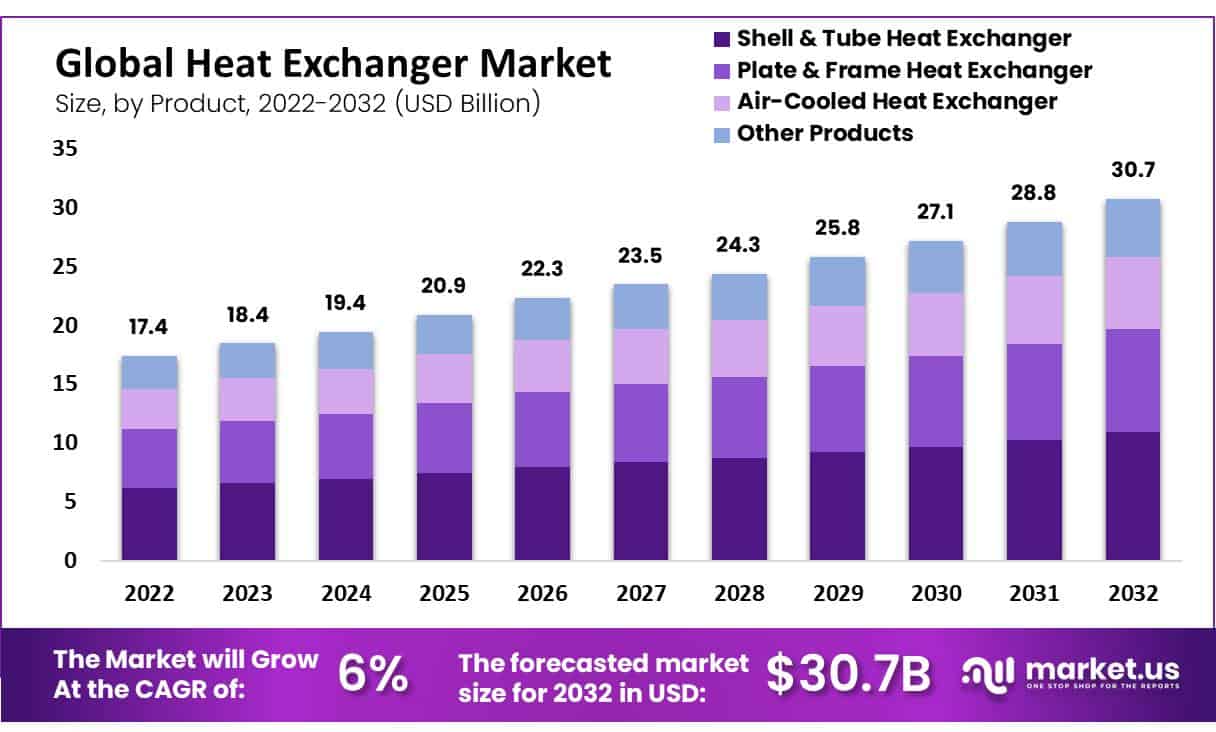

- The heat exchanger market is expected to experience steady growth over the next decade at a CAGR of 6%.

- In 2022, the heat exchanger market generated $17.4 billion in revenue, projected to increase to 30.7 billion in 2032.

- Among the various product types, in 2022, Shell and Tube Heat Exchangers accounted for USD 6.2 billion, Plate and Frame Heat Exchangers at USD 4.9 billion, Air-Cooled Heat Exchangers at USD 3.4 billion, and Other Products at USD 2.8 billion.

- Stainless steel emerges as the dominant player in this sector, commanding a significant 40% share. Its popularity can be attributed to its durability, corrosion resistance, and suitability for various applications.

- In 2022, Europe is poised to take the lead in the global market, securing a substantial 31.9% share.

- Utilizing shell and tube heat exchangers has the potential to lower temperatures by a significant margin, typically in the range of 30% to 40%.

- Thrust plates for heat exchangers must have a minimum thickness of 18 millimeters.

Global Heat Exchanger Market Overview

Heat Exchanger Market Size

- The heat exchanger market is expected to experience steady growth over the next decade at a CAGR of 6%.

- In 2022, the market generated $17.4 billion in revenue, projected to increase consistently in the coming years.

- By 2029, the market is forecasted to surpass the $25 billion mark, reaching $25.8 billion in revenue.

- The upward trajectory persists into the next decade, with revenues of $27.1 billion in 2030, $28.8 billion in 2031, and a significant milestone of $30.7 billion in 2032.

Global Heat Exchanger Market Size- By Product

- The global heat exchanger market is poised for steady growth in the coming years, with revenues projected to increase significantly.

- In 2022, the total market revenue stood at USD 17.4 billion.

- Among the various product types, Shell & Tube Heat Exchangers accounted for USD 6.2 billion, Plate & Frame Heat Exchangers for USD 4.9 billion, Air-Cooled Heat Exchangers for USD 3.4 billion, and Other Products for USD 2.8 billion.

- Over the next decade, the market is expected to witness robust expansion. By 2032, the total market revenue is forecasted to reach USD 30.7 billion, reflecting substantial growth.

- Shell and tube Heat Exchangers are projected to maintain their dominance, with revenues reaching USD 11.0 billion, followed by Plate and frame Heat Exchangers at USD 8.7 billion, Air-Cooled Heat Exchangers at USD 6.1 billion, and Other Products at USD 4.9 billion.

Heat Exchanger Market Share – By Construction Material

- The global heat exchanger market is characterized by various construction materials, each contributing to varying market share.

- Stainless steel emerges as the dominant player in this sector, commanding a significant 40% share. Its popularity can be attributed to its durability, corrosion resistance, and suitability for various applications.

- Copper follows closely behind with a 27% market share, offering excellent thermal conductivity and efficiency.

- Aluminum, with an 18% share, is also a notable contender, known for its lightweight properties and cost-effectiveness.

- The remaining 15% is accounted for by other materials, showcasing the market’s adaptability to cater to specific industry requirements.

Regional Analysis of Heat Exchanger Market

- In 2022, Europe is poised to take the lead in the global market, securing a substantial 31.9% share.

- This dominance is attributed to ongoing investments in infrastructure from the public and private sectors, fueling a rising demand for these products.

- Meanwhile, North America, particularly the United States and Canada, is expected to experience a notable uptick in product demand, primarily due to increased oil and natural gas exploration activities.

- In the Asia Pacific region, the heat exchanger market is set to witness a robust 6.2% growth during the forecast period.

Types of Heat Exchangers

Shell and Tube Heat Exchangers

- Utilizing shell and tube heat exchangers has the potential to lower temperatures by a significant margin, typically in the range of 30% to 40%.

- The shell’s inner diameter measures 66 millimeters, while the outer diameter is slightly larger at 70 millimeters. In contrast, the tubes have an inner diameter of 12 millimeters and an outer diameter of 13 millimeters.

- On the shell side, the fluid in question is oil, with an inlet temperature of 60 degrees Celsius. In contrast, the tube side involves water as the fluid, entering the heat exchanger at a lower temperature of 27 degrees Celsius.

- Additionally, the flow rates differ significantly, with the oil on the shell side flowing at 300, 420, and 540 liters per hour, while the water on the tube side maintains a constant flow rate of 180 liters per hour.

Plate Heat Exchangers

- The materials used in the Plate Heat Exchangers products are expected to meet the technical specifications outlined in document EK.1.

- Manufacturing firms should possess TSE-HYB documents.

- Thrust plates for heat exchangers must have a minimum thickness of 18 millimeters.

- Plate heat exchangers must incorporate a three-channel gasket technology.

- The combined length of bolts and supports should be 1.6 times greater than the components used during assembly to enhance the heat exchangers’ capacity.

Finned Tube Heat Exchangers

- The specifications for finned tube heat exchangers with a plain fin pattern encompass a range of parameters.

- These heat exchangers can have one to four rows of fins.

- The tubes’ outer diameter (OD) varies between 0.031 to 0.052 feet or 0.375 to 0.625 inches.

- The fin pitch, indicating the number of fins per foot or inch, falls within a range of 96 to 168, translating to 8 to 14 fins per inch.

- The tube spacing, measured in feet or inches, spans from 0.083 to 0.125 feet or 1 to 1.5 inches.

- These specifications are critical in designing and selecting finned tube heat exchangers tailored to specific heat transfer requirements and applications.

- The finned tube heat exchanger coil has specific parameters to define its design and functionality.

- It features a frontal height of 18 inches and a frontal width of 18 inches. The coil has six circuits, and each row in each circuit contains three tubes.

Heating Medium Used in Heat Exchangers

- Hot water, with an applicable temperature range of 60 to 90°C, offers several advantages in heating applications. It boasts excellent thermal properties, including a high specific heat capacity and efficient heat transmission coefficient.

- Additionally, hot water maintains a low viscosity and remains stable across its temperature range. It is safe to handle and not flammable, ensuring operational safety. However, using hot water does require ongoing maintenance to maintain water quality and the associated equipment.

- Due to its elevated condensation temperature, saturated steam, ranging from 100 to 275°C, offers efficient heating benefits with high heat output per unit mass. Precise temperature control is achieved by adjusting steam pressure.

- Steam provides cost-effective heat exchange and safety advantages. Yet, addressing inefficiencies like boiler blowdown and maintenance, including steam traps and leaks, is crucial. Additionally, two-phase flows may affect pipe integrity.

- Hot oil offers efficient heating with temperatures between 180 to 300°C. It surpasses steam in temperature and efficiency, reducing the risk of high tube-wall temperatures in fired heaters.

Common Cooling-media Applications

- Cooling mediums come with specific operating ranges and temperature applicabilities relative to ambient air.

- Chilled water operates effectively from 5 to 12°C, making it suitable for cooling below ambient temperatures.

- Cooling water, on the other hand, operates in the broader range of 32 to 60°C, covering ambient temperatures and extending up to 100°C.

- Air cooling, at atmospheric temperatures, is primarily effective for temperatures above 60°C.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)