Table of Contents

Introduction

Heat Exchanger Statistics: Heat exchangers are crucial in various industries, efficiently transferring heat between fluids without direct contact.

They have heating, cooling, and temperature control applications, including HVAC, power generation, and chemical processing. These devices allow heat to flow through solid walls or plates, separating hot and cold fluids.

Common types include shell, tube, Plate, and finned tube heat exchangers. Regular maintenance is essential to ensure their efficiency, as factors like fouling and corrosion can affect their performance.

In summary, heat exchangers play a vital role in diverse industrial processes. Making understanding their basics essential for professionals in relevant fields.

Editor’s Choice

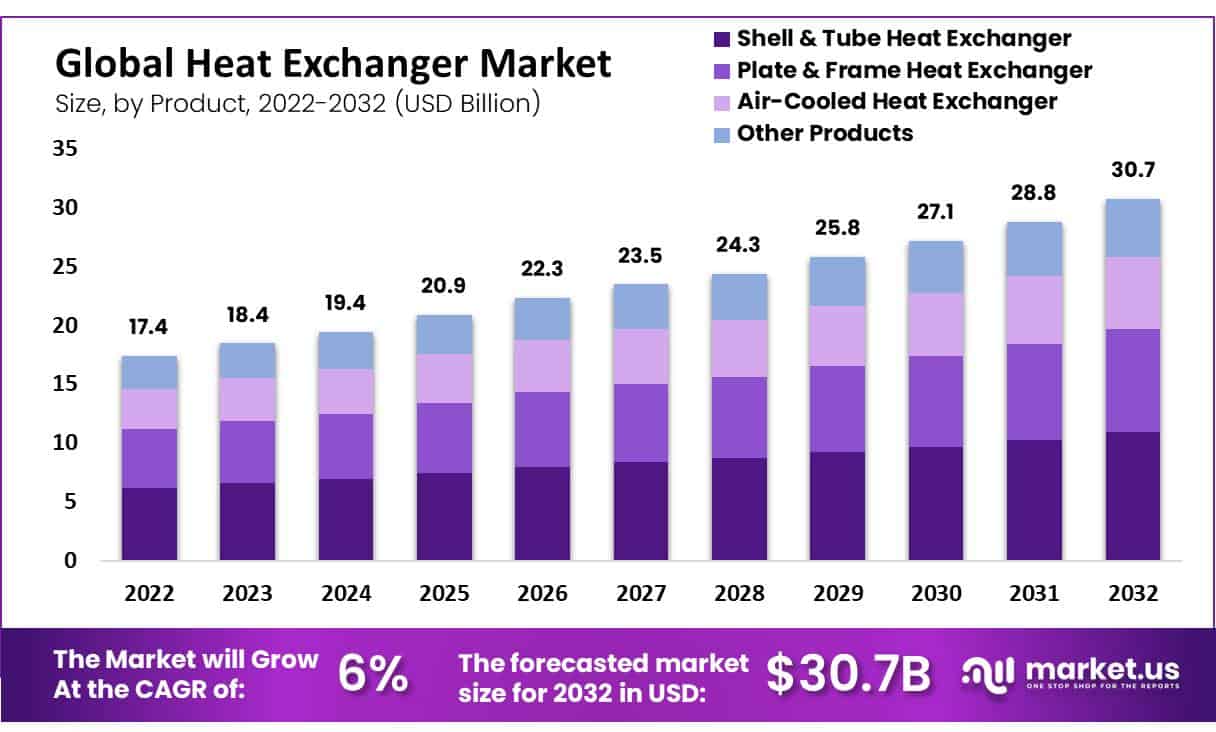

- The heat exchanger market is expected to experience steady growth over the next decade at a CAGR of 6%.

- In 2022, the heat exchanger market generated $17.4 billion in revenue, projected to increase to 30.7 billion in 2032.

- Among the various product types, in 2022, Shell and Tube Heat Exchangers accounted for USD 6.2 billion, Plate and Frame Heat Exchangers at USD 4.9 billion, Air-Cooled Heat Exchangers at USD 3.4 billion, and Other Products at USD 2.8 billion.

- Stainless steel emerges as the dominant player in this sector, commanding a significant 40% share. It is popular because it can be attributed to its durability and corrosion resistance. And suitability for various applications.

- In 2022, Europe is poised to take the lead in the global market. Securing a substantial 31.9% share.

- Utilizing shell and tube heat exchangers has the potential to lower temperatures by a significant margin, typically in the range of 30% to 40%.

- Thrust plates for heat exchangers must have a minimum thickness of 18 millimeters.

Global Heat Exchanger Market Statistics

Global Heat Exchanger Market Size

- The market is expected to experience growth over the decade at a CAGR of 6%.

- In 2022, the market generated $17.4 billion in revenue, projected to increase consistently in the coming years.

- In 2023, the revenue is expected to reach $18.4 billion, marking a modest but positive growth trajectory.

- The trend continues with revenues of $19.4 billion in 2024 and $20.9 billion in 2025. Indicating a gradual acceleration in market expansion.

- As we move further into the future, the heat exchanger market is anticipated to witness more substantial growth, with revenues of $22.3 billion in 2026, $23.5 billion in 2027, and $24.3 billion in 2028.

- By 2029, the market is forecasted to surpass the $25 billion mark, reaching $25.8 billion in revenue.

- The upward trajectory persists into the next decade, with revenues of $27.1 billion in 2030, $28.8 billion in 2031, and a significant milestone of $30.7 billion in 2032.

- This data highlights the robust and promising outlook for the heat exchanger industry. Driven by technological advancements. Increasing demand for energy-efficient solutions, and expanding industrial sectors requiring heat exchange capabilities.

(Source: Market.us)

Heat Exchanger Market Size – By Product

- The global heat exchanger market is poised for steady growth in the coming years, with revenues projected to increase significantly.

- In 2022, the total market revenue stood at USD 17.4 billion.

- Among the various product types, Shell & Tube Heat Exchangers accounted for USD 6.2 billion, Plate & Frame Heat Exchangers for USD 4.9 billion, Air-Cooled Heat Exchangers for USD 3.4 billion, and Other Products for USD 2.8 billion.

- Over the next decade, the market is expected to witness robust expansion. By 2032, the total market revenue is forecasted to reach USD 30.7 billion, reflecting substantial growth.

- Shell and tube Heat Exchangers are projected to maintain their dominance, with revenues reaching USD 11.0 billion, followed by Plate and frame Heat Exchangers at USD 8.7 billion, Air-Cooled Heat Exchangers at USD 6.1 billion, and Other Products at USD 4.9 billion.

- This promising trajectory underscores the increasing demand for heat exchangers across various industries. Highlighting their vital role in efficient heat transfer processes.

(Source: Market.us)

Global Heat Exchanger Market Share – By Construction Material

- The global heat exchanger market is characterized by various construction materials, each contributing to varying market share.

- Stainless steel emerges as the dominant player in this sector, commanding a significant 40% share. Its popularity can be attributed to its durability, corrosion resistance, and suitability for various applications.

- Copper follows closely behind with a 27% market share, offering excellent thermal conductivity and efficiency.

- Aluminum, with an 18% share, is also a notable contender, known for its lightweight properties and cost-effectiveness.

- The remaining 15% is accounted for by other materials, showcasing the market’s adaptability to cater to specific industry requirements.

- This diversity in construction materials underscores the versatility of heat exchangers. Catering to various industrial and commercial needs while accommodating different budget constraints and performance criteria.

(Source: Market.us)

Regional Analysis of Heat Exchanger Market

- In 2022, Europe is poised to take the lead in the global market, securing a substantial 31.9% share.

- This dominance is attributed to ongoing investments in infrastructure from the public and private sectors, fueling a rising demand for these products.

- Meanwhile, North America, particularly the United States and Canada, is expected to experience a notable uptick in product demand. Primarily due to increased oil and natural gas exploration activities.

- In the Asia Pacific region, the heat exchanger market is set to witness a robust 6.2% growth during the forecast period.

- This impressive expansion is a direct result of the swift industrialization observed in developing nations across the Asia Pacific. Accompanied by a surge in industrial and commercial project investments.

(Source: Market.us)

Types of Heat Exchanger Statistics

Shell and Tube Heat Exchanger Statistics

- Utilizing shell and tube heat exchangers has the potential to lower temperatures by a significant margin, typically in the range of 30% to 40%.

- The shell’s inner diameter measures 66 millimeters, while the outer diameter is slightly larger at 70 millimeters. In contrast, the tubes have an inner diameter of 12 millimeters and an outer diameter of 13 millimeters.

- These geometric specifications are crucial in determining the heat exchange efficiency and overall heat exchanger performance.

- Additionally, it’s worth noting that the materials used for construction are steel for the shell and copper for the tubes. Which can influence the heat transfer characteristics and durability of the heat exchanger.

- On the shell side, the fluid in question is oil, with an inlet temperature of 60 degrees Celsius. In contrast, the tube side involves water as the fluid, entering the heat exchanger at a lower temperature of 27 degrees Celsius.

- Additionally, the flow rates differ significantly, with the oil on the shell side flowing at 300, 420, and 540 liters per hour. While the water on the tube side maintains a constant flow rate of 180 liters per hour.

- These temperature and flow rate parameters are essential in determining the heat transfer performance and overall efficiency of the heat exchanger in its specific application.

(Source: IOP Conference Series: Materials Science and Engineering)

Plate Heat Exchanger Statistics

- The materials used in the Plate Heat Exchangers products are expected to meet the technical specifications outlined in document EK.1.

- Manufacturing firms should possess TSE-HYB documents.

- Thrust plates for heat exchangers must have a minimum thickness of 18 millimeters.

- Plate heat exchangers must incorporate a three-channel gasket technology.

- The combined length of bolts and supports should be 1.6 times greater than the components used during assembly to enhance the heat exchangers’ capacity.

- The corrugated plate heat exchanger’s geometrical dimensions are as follows: the corrugation angle, denoted as β, is set at 60 degrees, while the corrugation pitch, represented as ‘t,’ measures 9 millimeters.

- There are a total of 28 corrugated plates within the exchanger, with each Plate having a length (L) of 170 millimeters, a width (W) of 70 millimeters, a depth (2bc) of 4.8 millimeters, and a thickness (δ) of 0.5 millimeters.

- These plates’ cumulative heat transfer area (A) amounts to 0.378 square meters, and the surface enlargement ratio is calculated at 1.13.

- These geometric specifications are integral in determining the heat exchanger’s performance and efficiency in various applications.

(Source: ekinendustriyel, Science Direct)

Finned Tube Heat Exchanger Statistics

- The specifications for finned tube heat exchangers with a plain fin pattern encompass a range of parameters.

- These heat exchangers can have one to four rows of fins.

- The tubes’ outer diameter (OD) varies between 0.031 to 0.052 feet or 0.375 to 0.625 inches.

- The fin pitch, indicating the number of fins per foot or inch, falls within a range of 96 to 168, translating to 8 to 14 fins per inch.

- The tube spacing, measured in feet or inches, spans from 0.083 to 0.125 feet or 1 to 1.5 inches.

- These specifications are critical in designing and selecting finned tube heat exchangers tailored to specific heat transfer requirements and applications.

- The finned tube heat exchanger coil has specific parameters to define its design and functionality.

- It features a frontal height of 18 inches and a frontal width of 18 inches. The coil has six circuits, and each row in each circuit contains three tubes.

- The coil is oriented with a vertical face attitude, and the outer tube diameter measures 0.375 inches. The tubes themselves are vertically oriented, and their arrangement is staggered.

- The fins on the coil have a thickness of 0.005 inches and exhibit a flat-rippled edge geometry.

- The transverse tube spacing is 1 inch, while the longitudinal tube spacing measures 0.77 inches. These parameters collectively determine the coil’s performance and suitability for various heat exchange applications.

(Source: Georgia Institute of Technology)

Heating Medium Used in Heat Exchanger Statistics

- Hot water, with an applicable temperature range of 60 to 90°C, offers several advantages in heating applications. It boasts excellent thermal properties, including a high specific heat capacity and efficient heat transmission coefficient.

- Additionally, hot water maintains a low viscosity and remains stable across its temperature range. It is safe to handle and not flammable, ensuring operational safety. However, using hot water does require ongoing maintenance to maintain water quality and the associated heating equipment.

- Due to its elevated condensation temperature, saturated steam, ranging from 100 to 275°C, offers efficient heating benefits with high heat output per unit mass. Precise temperature control is achieved by adjusting steam pressure.

- Steam provides cost-effective heat exchange and safety advantages. Yet, addressing inefficiencies like boiler blowdown and maintenance, including steam traps and leaks, is crucial. Additionally, two-phase flows may affect pipe integrity.

- Hot oil offers efficient heating with temperatures between 180 to 300°C. It surpasses steam in temperature and efficiency, reducing the risk of high tube-wall temperatures in fired heaters.

- Molten salt, with a temperature range of 400 to 590°C, boasts higher operating temperatures than synthetic oils, which typically reach above 390°C. However, it does pose a freezing hazard.

- Flue gas or hot air, with temperatures from 750 to 1100°C, is a valuable yet waste heat source. It boosts boiler efficiency by recovering lost heat and reducing costs while improving emissions.

- However, there’s a risk of sulfuric acid condensation during heat recovery, leading to corrosion and fouling, which may require advanced materials for mitigation.

(Source: Ipieca Ltd.)

Common Cooling-media Applications

- Cooling mediums come with specific operating ranges and temperature applicabilities relative to ambient air.

- Chilled water operates effectively from 5 to 12°C, making it suitable for cooling below ambient temperatures.

- Cooling water, on the other hand, operates in the broader range of 32 to 60°C, covering ambient temperatures and extending up to 100°C.

- Air cooling, at atmospheric temperatures, is primarily effective for temperatures above 60°C.

- These different cooling mediums offer versatile options for managing heat and temperature in various applications.

(Source: Ipieca Ltd.)

Recent Developments

Acquisitions and Mergers:

- Alfa Laval acquires Sandymount Technologies: In early 2023, Alfa Laval acquired Sandymount Technologies, a company specializing in membrane filtration and concentration technology. This acquisition aims to enhance Alfa Laval’s heat exchanger offerings by integrating advanced concentration and separation solutions.

- Danfoss acquires BOCK GmbH: Danfoss completed its acquisition of BOCK GmbH, a leading manufacturer of natural refrigerant compressors, for $200 million in late 2023. This merger is expected to strengthen Danfoss’s position in the heat exchanger market by providing more energy-efficient solutions.

New Product Launches:

- SWEP’s B5T Heat Exchanger: In mid-2023, SWEP launched the B5T heat exchanger, designed for use in refrigeration and HVAC applications. The B5T offers high thermal efficiency and compact size, making it suitable for a wide range of industrial applications.

- Kelvion’s K°Bloc Heat Exchanger: Kelvion introduced the K°Bloc heat exchanger in early 2024. This product is designed for high-pressure applications and offers improved performance and durability, catering to industries such as oil and gas and chemical processing.

Funding:

- SPX FLOW secures $150 million: SPX FLOW, a global supplier of highly engineered solutions, including heat exchangers, raised $150 million in funding in 2023 to expand its product portfolio and enhance its manufacturing capabilities.

- Thermofin secures $100 million: In early 2024, Thermofin, a manufacturer of heat exchangers and refrigeration equipment, secured $100 million to invest in research and development and to expand its production facilities.

Technological Advancements:

- Additive Manufacturing: Advances in additive manufacturing (3D printing) are being applied to heat exchanger production, allowing for more complex and efficient designs that were previously impossible to manufacture with traditional methods.

- Nanotechnology Integration: The integration of nanotechnology in heat exchanger materials is improving thermal conductivity and efficiency, leading to more effective heat transfer and reduced energy consumption.

Market Dynamics:

- Growth in Heat Exchanger Market: The global heat exchanger market is projected to grow at a CAGR of 6.5% from 2023 to 2028, driven by increasing demand in power generation, HVAC, and industrial applications, as well as the need for energy-efficient solutions.

- Rising Demand in Renewable Energy: The shift towards renewable energy sources, such as solar and wind power, is driving demand for heat exchangers designed to optimize energy transfer in these systems, supporting sustainable energy initiatives.

Regulatory and Strategic Developments:

- EU’s Energy Efficiency Directive: The European Union’s Energy Efficiency Directive, revised in 2023, includes stricter requirements for energy efficiency in industrial processes, encouraging the adoption of advanced heat exchangers to meet regulatory standards.

- US EPA Regulations: The US Environmental Protection Agency (EPA) introduced new regulations in early 2024 aimed at reducing greenhouse gas emissions from industrial processes, promoting the use of more efficient heat exchangers.

Research and Development:

- Microchannel Heat Exchangers: R&D efforts are focusing on the development of microchannel heat exchangers, which offer high heat transfer efficiency and compact size, making them ideal for applications in electronics cooling and automotive industries.

- Advanced Materials Research: Researchers are exploring the use of advanced materials, such as graphene and advanced alloys, to improve the performance and durability of heat exchangers, aiming to enhance their thermal properties and resistance to corrosion.

Conclusion

Heat Exchanger Statistics – Heat exchangers are vital components across various industries, enabling efficient heat transfer between fluids.

They come in diverse types and designs, tailored to specific needs influenced by temperature, fluid characteristics, and space availability.

Well-designed and maintained heat exchangers can significantly boost energy efficiency, cut operational expenses, and support environmental sustainability.

Nevertheless, challenges such as fouling, corrosion, and maintenance demand attention. In an era of technological advancement and evolving industries, heat exchangers remain indispensable in thermal engineering, ensuring effective heat utilization in various processes.

FAQs

A heat exchanger is designed to efficiently transfer heat between two or more fluids (liquids or gases) without mixing them.

Heat exchangers control the temperature of fluids, either heating or cooling them, in various industrial processes and applications, including HVAC systems, chemical processing, and power generation.

Common types include shell and tube heat exchangers, plate heat exchangers, and finned tube heat exchangers, each with its design and advantages.

Heat exchangers allow heat to flow from one fluid to another through a conductive barrier, such as tubes or plates while keeping the two fluids separate.

Factors include the design, flow rates of the fluids, temperature differences, and the type of fluids used.

Regular maintenance involves cleaning to prevent fouling, inspecting corrosion, and checking for leaks. Proper fluid treatment and monitoring are also essential.

Some heat exchangers are designed to handle high-pressure fluids, and the choice depends on the specific application and requirements.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)