Table of Contents

Introduction

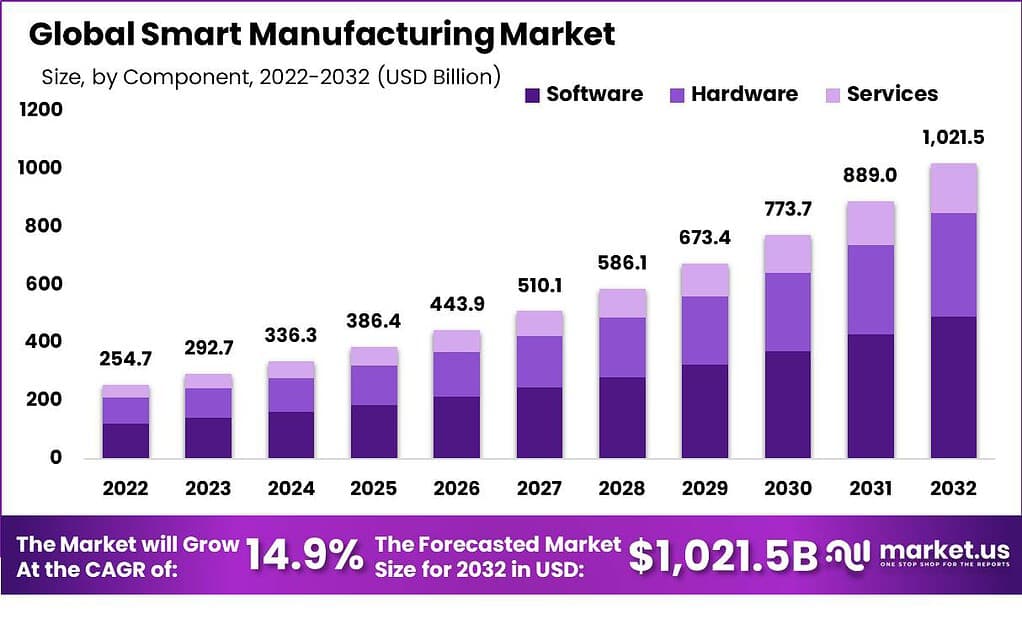

The global Smart Manufacturing Market is projected to reach a valuation of USD 1,021.5 billion by 2032, exhibiting a steady compound annual growth rate (CAGR) of 14.9% from 2024 to 2033.

Smart manufacturing refers to the integration of advanced information and manufacturing technologies to enhance the efficiency, productivity, and competitiveness of industrial production processes. This approach leverages the power of data analytics, artificial intelligence, and the Internet of Things (IoT) to optimize manufacturing operations and supply chain management. The core objective is to create a highly adaptable, resource-efficient, and cost-effective production environment.

The smart manufacturing market is experiencing significant growth, driven by the increasing need for improved data management, predictive maintenance, and automated production processes across various industries. Key sectors adopting these technologies include automotive, aerospace, electronics, and healthcare, among others. Market analysts forecast a continuing rise in investments in smart manufacturing solutions, reflecting the ongoing shift towards Industry 4.0 standards.

This transformation is seen as essential for companies aiming to improve operational efficiencies and maintain competitive advantages in an increasingly digital economy. The market growth can be attributed to these technological advancements and the rising emphasis on sustainable manufacturing practices

Key Takeaways

- The Global Smart Manufacturing Market was valued at USD 292.7 billion in 2023, with an estimated CAGR of 14.9% between 2023 and 2032.

- Increasing demand for production and efficient operations is a primary driver of market growth.

- High initial investment could pose a challenge to market expansion.

- Software dominates the market, accounting for a major revenue share of 48.2% in the component segment.

- Discrete control systems hold a significant revenue share of 21.8% in the technology segment.

- The automotive industry leads the end-use industry segment with a major revenue share of 23.6%.

- Integration of advanced technologies is expected to create lucrative opportunities in the market.

- The adoption of edge computing is a trending phenomenon in the market.

- Asia Pacific dominates the market, holding a major revenue share of 35.8%.

Smart Manufacturing Statistics

- Industry 4.0 market size is expected to be worth around USD 482 billion by 2032, growing at a CAGR of 20.7% during the forecast period from 2023 to 2032.

- By 2025, it is anticipated that data from smart manufacturing technologies could bolster the annual contribution to GDP by as much as $530 billion. This projection underscores the transformative potential of integrating advanced technologies in manufacturing processes.

- A significant proportion of manufacturers, approximately 64%, have reported that the adoption of smart manufacturing has enhanced their productivity. This improvement is indicative of the efficiencies gained through digital automation and process optimization.

- The Global Collaborative Robots Market is poised for remarkable growth. Forecasts suggest that the market size could reach approximately USD 23.5 Billion by 2033, up from USD 1.5 Billion in 2023, with a Compound Annual Growth Rate (CAGR) of 31.7% during the forecast period from 2024 to 2033.

- In 2023, venture capital funding for smart manufacturing startups achieved a new zenith, surpassing $2 billion. This record-high investment reflects a burgeoning interest in pioneering technologies within the sector.

- A survey by KPMG International involving 182 Chief Executive Officers (CEOs) from major manufacturing companies across Europe, Asia, and North America revealed a strong sentiment of confidence in achieving profitable growth over the next three years, despite potential economic downturns in 2023.

- Global expenditure on smart factory solutions reached $120 billion in 2023. Leading applications of these solutions include predictive maintenance and asset tracking, highlighting the critical areas of focus for current investments.

- The Biden-Harris Administration announced an investment of $50 million from President Biden’s Bipartisan Infrastructure Law, aimed at fostering smart manufacturing in small- and medium-sized facilities. Moreover, the U.S. Department of Energy (DOE), the U.S. Department of Treasury, and the Internal Revenue Service (IRS) unveiled $4 billion in tax credits for over 100 projects across 35 states, aimed at bolstering clean energy manufacturing and reducing greenhouse gas emissions at industrial sites.

- In 2022, the manufacturing sector experienced the highest proportion of cyber-attacks among major industries. The third quarter of 2023 witnessed a 15% increase in cyber-attacks compared to the previous period, highlighting ongoing vulnerabilities that need addressing to secure industrial operations.

Plan your Next Best Move. Purchase the Report for Data-driven Insights

Emerging Trends

- Integration of Advanced Technologies: Artificial intelligence, machine learning, and advanced analytics are being increasingly adopted to optimize processes and drive efficiencies in smart manufacturing. These technologies enable manufacturers to make data-driven decisions and automate routine tasks.

- Predictive Maintenance and Digital Twins: The use of IoT sensors, coupled with AI algorithms for predictive maintenance, continues to grow. This approach allows for real-time monitoring and proactive maintenance planning. Digital twins complement this by simulating physical systems to optimize processes before they are implemented.

- Supply Chain Restructuring: In response to recent disruptions, there’s a trend towards restructuring supply chains, focusing on nearshoring and reshoring to mitigate risks and improve control over logistics and production quality.

- Rise of Microfactories: The adoption of small, flexible production units, known as microfactories, is on the rise. These facilities support on-demand production and customization, adapting quickly to consumer demands and market changes.

- IIoT and Enhanced Connectivity: The Industrial Internet of Things (IIoT) remains integral to smart manufacturing, enabling extensive data collection and real-time monitoring across processes. This connectivity leads to improved efficiency, safety, and innovation.

Top Use Cases

- Real-Time Equipment Monitoring: Using IIoT, manufacturers can monitor equipment performance continuously to optimize operational efficiency.

- Predictive Maintenance: This extends beyond identifying potential equipment failures to predictive resolution, which not only predicts issues but also suggests solutions, enhancing equipment reliability and longevity.

- Supply Chain Optimization: Technologies like cloud computing and IIoT enable greater transparency and efficiency in the supply chain, optimizing logistics and monitoring materials and products throughout their journey.

- Product Customization and 3D Printing: Smart manufacturing enables rapid production of customized products through technologies like 3D printing, allowing for complex designs at reduced costs.

- Enhanced Product Quality and Compliance: By utilizing data analytics and digital twin technology, manufacturers can monitor and adjust production processes in real-time, ensuring products meet high standards and regulations.

Major Challenges

- Cybersecurity Risks: As smart manufacturing involves extensive data connectivity, securing these networks against cyber threats is a critical challenge.

- High Initial Investment: The costs associated with implementing smart manufacturing solutions can be prohibitively high, particularly for smaller enterprises.

- Skilled Workforce Shortage: There is a notable shortage of professionals skilled in advanced manufacturing technologies, hindering the adoption and efficient use of these systems.

- Integration with Existing Systems: Integrating advanced smart technologies with older existing systems presents significant technical challenges.

- Maintaining Product Quality and Compliance: Ensuring that manufacturing processes meet quality standards and regulatory requirements while adopting new technologies is a persistent challenge.

Market Opportunities

- Adoption of Industry 4.0 Technologies: The shift towards Industry 4.0 technologies like IoT, AI, and robotics presents vast opportunities for efficiency and innovation.

- Cloud-Based Solutions: There is an increasing demand for cloud-based solutions that provide scalability and enhanced data management capabilities.

- 3D Printing: 3D printing offers significant opportunities for cost reduction and innovation by enabling rapid prototyping and manufacturing.

- Sustainable and Green Manufacturing: There is a growing focus on sustainable manufacturing practices that reduce environmental impact and improve energy efficiency.

- Expansion in Emerging Markets: Emerging markets provide significant growth opportunities as they continue to invest in modernizing their manufacturing capabilities.

Recent Developments

- Honeywell’s Digital Prime Solution: In June 2023, Honeywell introduced its cloud-based digital twin, the Honeywell Digital Prime solution, simplifying process control oversight and enhancing maintenance accuracy.

- Siemens’ Industrial Operations X: In April 2023, Siemens Digital Industries launched Industrial Operations X, an interconnected suite designed to automate and oversee industrial manufacturing processes, contributing to operational efficiency.

- Also in April 2023, Stratasys launched GrabCAD Print Pro software, which integrates quality assurance features from its recent acquisition, Riven. The software is designed for Stratasys 3D printers and focuses on increasing the accuracy of printed parts, minimizing waste, and speeding up production, targeting manufacturers producing end-use parts at scale

Conclusion

The smart manufacturing market is poised for significant growth, driven by advancements in technology and increasing demand for automation and data-driven decision-making. While the market faces challenges such as cybersecurity risks and the need for high initial investments, the opportunities for innovation and efficiency gains present a positive outlook. Companies that can navigate these challenges and leverage new technologies stand to benefit greatly from the ongoing industrial transformation. Emphasizing sustainable practices and investing in workforce training can further enhance their competitive edge in this dynamic market landscape.