Table of Contents

Introduction

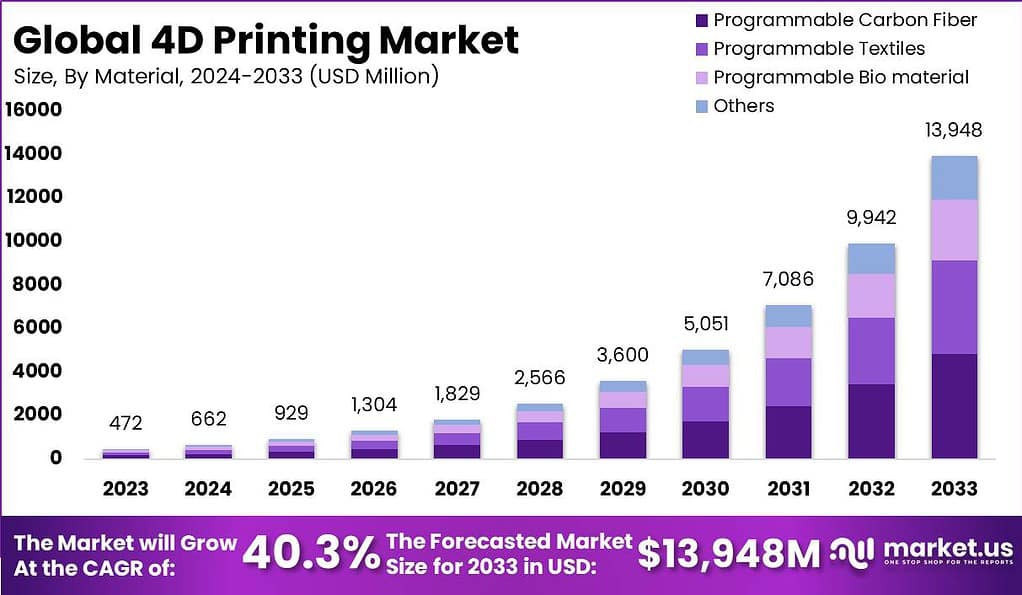

According to market.us, The Global 4D Printing Market is projected to grow from USD 472 million in 2023 to approximately USD 13,948 million by 2033, with an impressive CAGR of 40.3% over the forecast period from 2024 to 2033. 4D printing is an advanced form of 3D printing where the manufactured objects can change their shape or properties over time in response to external stimuli, such as temperature, light, or water. This technology builds on the foundation of 3D printing by adding the dimension of time as an aspect of the printed object, which allows it to transform or self-assemble.

The 4D printing market is at the forefront of technological innovation in the additive manufacturing sector. It promises to revolutionize various industries by enabling more dynamic, adaptive, and efficient production processes. The potential applications of 4D printing span across fields such as aerospace, healthcare, automotive, and construction. In aerospace, for example, 4D printed materials could be used to create components that change shape in response to atmospheric conditions, optimizing performance without additional mechanical inputs.

Despite its promise, the 4D printing market faces several challenges. The technology is still in its nascent stages, with high costs and limited material availability posing significant barriers to widespread adoption. Additionally, there are technical challenges related to the programming of the materials’ transformation behaviors and the overall reliability of the final products.

However, the market for 4D printing also presents substantial opportunities. As research progresses, the cost of 4D printing technologies is expected to decrease, making them more accessible to a broader range of industries. Moreover, the ongoing development of new materials and processes is continually expanding the potential applications of 4D printing. This advancement could lead to significant breakthroughs in manufacturing custom-made objects that can adapt to environmental changes or perform pre-programmed functions over time.

4D Printing Statistics

- According to a comprehensive analysis conducted by Market.us, the Global 3D Printing Market is poised for substantial growth. The market’s valuation is expected to escalate from USD 19.8 Billion in 2023 to approximately USD 135.4 Billion by 2033. This growth trajectory suggests a Compound Annual Growth Rate (CAGR) of 21.2% during the forecast period from 2024 to 2033.

- In parallel, the AI in 3D Printing Market is projected to witness a significant surge in its valuation. From an initial market size of USD 1.6 Billion in 2023, it is forecasted to reach USD 34.8 Billion by 2033. The anticipated expansion, marked by a robust CAGR of 36.5% from 2024 to 2033, underscores the dynamic integration of artificial intelligence technologies within the 3D printing sector.

- The 4D Printing Market is expected to reach USD 13,948 million by 2033, up from USD 472 million in 2023, with a CAGR of 40.3% from 2024 to 2033.

- In 2023, the Programmable Carbon Fiber segment held a significant market share, accounting for 34.6% of the total market.

- The Aerospace and Defense segment was the leading sector in the 4D printing market in 2023, securing 35.6% of the market share.

- North America emerged as the dominant region for 4D printing in 2023, holding 37.4% of the global market, with revenues of USD 176.5 million.

- The Global 4D Printing Market is projected to experience substantial growth over the next decade, buoyed by innovative advancements in material technologies. In 2023, the market stands at an estimated $472 million, with Programmable Carbon Fiber being the predominant driver of this initial phase. By 2024, the market valuation is expected to ascend to $662 million, maintaining momentum primarily through the same leading segment.

- The upward trajectory is set to continue, with the market forecast to reach $929 million in 2025. At this stage, Programmable Textiles and Programmable Biomaterials are anticipated to begin making notable contributions to the market expansion.

- Looking ahead to 2026, the market is projected to grow further to $1,304 million, with enhancements across all segments. The growth narrative extends into 2027, where the market is anticipated to burgeon to $1,829 million, still predominantly propelled by Programmable Carbon Fiber.

- The expansion trend is poised to accelerate, with the market size projected to climb to $2,566 million in 2028 and further to $3,600 million in 2029, backed by significant increases across all material segments.

- By the dawn of 2030, the market is forecasted to escalate impressively to $5,051 million, with Programmable Biomaterial and other innovative segments showcasing pronounced growth. The progression continues robustly, with market sizes of $7,086 million and $9,942 million expected for 2031 and 2032 respectively, where Programmable Carbon Fiber maintains a substantial role in the growth narrative.

- Ultimately, by 2033, the market is projected to surge to an impressive $13,948 million, marking contributions from all segments and reflecting a robust compound annual growth rate (CAGR) of 40.3% from 2024 to 2033.

Emerging Trends in 4D Printing

- Smart Material Integration: The core of 4D printing lies in smart materials, such as shape-memory polymers and hydrogels, which are capable of changing shape in response to environmental stimuli. These materials are increasingly used in various sectors, enhancing the functionality and adaptability of printed objects.

- Biomedical Applications: There is a significant surge in the application of 4D printing within the healthcare sector, particularly for creating more responsive and adaptable medical devices, such as drug delivery systems and bioprinted tissues and organs, which can mimic natural biological processes.

- Hybrid Manufacturing Techniques: Combining traditional manufacturing processes with 4D printing allows for the creation of more complex and functionally enhanced products. This integration is particularly beneficial in industries like aerospace and automotive, where customized and performance-specific components are crucial.

- Environmental Sustainability: 4D printing is contributing to sustainability efforts by reducing material waste through precise and efficient use of resources. This trend is expected to grow as industries continue to seek environmentally friendly manufacturing processes.

- Expansion in Construction and Architecture: Programmable materials are being used to develop adaptive building materials and structures that can respond to environmental changes, promising more sustainable and efficient construction practices.

Top Use Cases for 4D Printing

- Aerospace Components: In aerospace, 4D printing is used to create parts that can adapt to different environmental conditions without human intervention, such as airfoils that change shape to optimize aerodynamics during flight.

- Self-Adjusting Clothing and Wearables: In the consumer goods sector, 4D printing is utilized to produce clothing and wearable devices that can change in response to body temperature or environmental conditions, enhancing comfort and functionality.

- Medical Devices and Implants: The technology is particularly transformative in healthcare, enabling the production of custom-fit implants and devices that can adapt to the body’s changes over time or react dynamically to the physiological needs of patients.

- Dynamic Infrastructure: 4D printing allows for the creation of infrastructure components that can respond to environmental stimuli, such as pipes that expand or contract in response to water flow changes or temperature.

- Automotive Parts: Automotive industries are leveraging 4D printing to develop components that can adapt to heat and pressure changes, improving performance and durability of vehicles under varying operational conditions.

Major Challenges

- Skill Gap in Workforce: The 4D printing industry requires professionals with specialized knowledge and experience in advanced technologies. The scarcity of such skilled professionals is a significant barrier, limiting the technology’s broader adoption and application.

- Material Stability and Reliability: As 4D printing involves materials that respond to environmental stimuli, ensuring consistent material behavior under various conditions is challenging. This variability can affect the reliability and stability of the final products.

- High Investment Costs: The initial costs associated with developing 4D printing technologies are substantial. This financial requirement can deter new entrants and limit the expansion of existing operations in the 4D printing market.

- Regulatory and Standardization Issues: The lack of established standards and clear regulatory guidelines for 4D printing applications, especially in critical sectors like healthcare and aerospace, complicates the development and approval processes.

- Limited Public Awareness and Market Maturity: Despite its potential, 4D printing is still in the early stages of public acceptance and market integration. The technology’s novelty contributes to a cautious approach from industries and consumers alike, slowing its market penetration.

Market Opportunities

- Advancements in Material Science: Ongoing research and development in material science are leading to the creation of innovative materials with properties like shape memory and self-healing capabilities. These advancements open up new applications across various industries, including healthcare, automotive, and aerospace.

- Customization and Personalization: The ability of 4D printing to produce customized and personalized products efficiently is a significant market driver. This aspect is particularly valuable in sectors such as healthcare for creating bespoke medical implants and devices.

- Sustainability: 4D printing promotes sustainability by enabling the creation of products that can adapt to changes and extend their usability, potentially reducing waste. This attribute aligns well with the growing global emphasis on sustainable production practices.

- Integration with IoT and Smart Technologies: The integration of 4D printing with IoT and smart technologies offers potential for innovations like smart textiles and responsive infrastructure, which could transform multiple sectors including construction and wearables.

- Expansion in Emerging Markets: Rapid industrialization in emerging markets presents a significant opportunity for the adoption of 4D printing technologies. Countries like China and India are showing increased interest, which could drive substantial market growth.

Recent Development

- Launch of CO-AM Platform: In May 2023, Materialise introduced its CO-AM software platform, designed to connect and automate the additive manufacturing process, providing users with a comprehensive suite of tools for managing their 3D printing operations. This platform aims to improve efficiency and streamline workflows in the 4D printing sector

- In August 2023, Stratasys moved forward with its merger with Desktop Metal. The merger aims to combine the strengths of both companies to drive innovation in additive manufacturing. Stratasys shareholders will hold about 59% of the combined company, while Desktop Metal stockholders will own approximately 41%.

- In February 2023, Autodesk Research collaborated with MIT’s Self-Assembly Lab to develop Cyborg, a design platform that spans applications from nano-scale to human-scale. This software allows for simulated self-assembly and programmable materials, enhancing the capabilities of 4D printing.

Conclusion

In conclusion, 4D printing is set to transform various industries by introducing the dimension of time to 3D printed objects, enabling them to change shape or function in response to external stimuli. This technology promises significant advancements in aerospace, automotive, medical, and environmental applications by creating adaptable, efficient, and personalized products.

However, the development of smart materials and the need for infrastructure adaptation pose challenges that need to be addressed. As research and development continue, the potential for 4D printing to revolutionize manufacturing, construction, robotics, and consumer goods becomes increasingly tangible, paving the way for a more innovative and adaptable future.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)