Table of Contents

Introduction

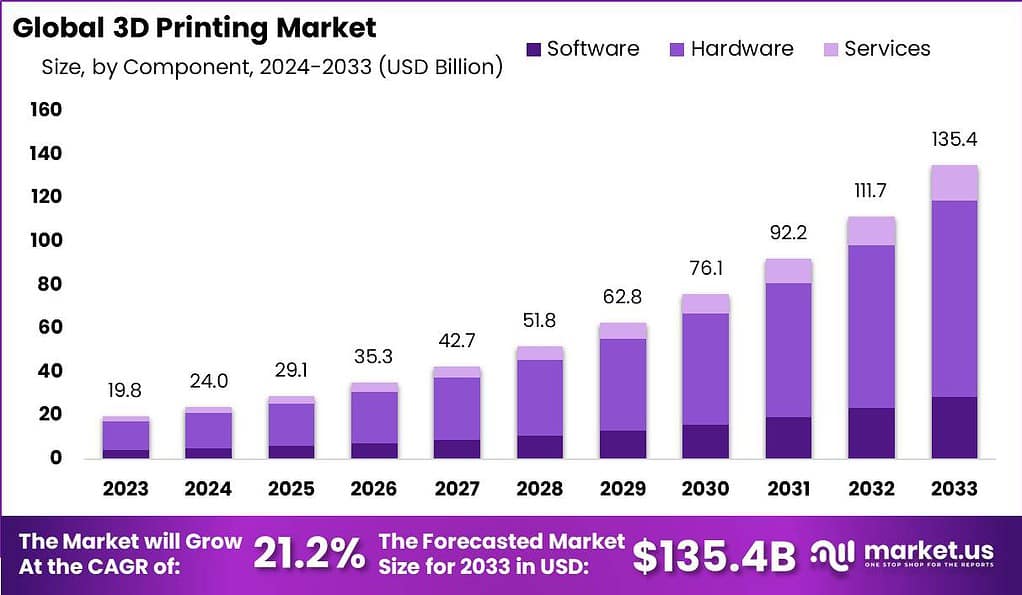

The global 3D printing market was valued at USD 19.8 billion in 2023, and it is projected to reach an astonishing USD 135.4 billion by 2033. Such exceptional growth is expected to be driven by a robust compound annual growth rate (CAGR) of 21.2% during the forecast period from 2024 to 2033.

Several key factors contribute to the remarkable growth of the 3D printing market. Firstly, the increasing adoption of 3D printing across industries, including manufacturing, healthcare, automotive, aerospace, and consumer goods, is a significant growth factor. The ability of 3D printing technology to produce complex and customized objects with speed and precision has revolutionized traditional manufacturing processes.

Furthermore, the advancements in materials used for 3D printing, such as metals, polymers, ceramics, and composites, have expanded the range of applications and boosted market growth. Additionally, the cost-effectiveness and sustainability of 3D printing, along with its ability to reduce waste and enable on-demand production, have further fueled its adoption.

Despite the promising growth prospects, the 3D printing market also faces certain challenges. One of the primary challenges is the high initial investment required for 3D printing equipment and materials. Moreover, the limitations in terms of print speed, size, and quality for certain applications pose hurdles for widespread adoption. Overcoming these challenges will be crucial for the market to reach its full potential.

Key Takeaways

- The 3D printing market is anticipated to reach USD 135.4 billion by 2033, with a steady CAGR of 21.2% during the forecast period.

- Hardware dominates the market with over 67% share, followed by Software and Services.

- Industrial 3D Printers hold over 75% market share due to their precision and compatibility.

- Stereolithography leads with a market share of over 11%, known for exceptional precision and surface quality.

- Prototyping commands over 54% market share, facilitating rapid and cost-effective product development.

- Metal holds a commanding market share of over 53%, driven by its precision and durability.

- The North America held a leading position within the world of 3D printing with a staggering percentage of more than 35%.

- Leading companies include Stratasys Ltd, Materialise, EnvisionTec Inc, 3D Systems Inc, and GE Additive.

- In 2023, there will be a significant increase in the adoption of 3D printing in the healthcare industry, with an expected growth rate of 25%. This growth is driven by the rising demand for personalized medical devices and implants, as 3D printing enables precise customization to fit individual patient needs.

- By the year 2024, the number of 3D printing service providers worldwide is projected to exceed 10,000, catering to the increasing demand across various sectors. These service providers offer 3D printing solutions to businesses and individuals, making the technology more accessible and enabling a wide range of applications.

- The aerospace industry is also poised for substantial growth in 3D printing adoption. It is projected to increase by 30% in 2023, as manufacturers leverage the technology to produce lightweight and complex parts. 3D printing allows for intricate designs and reduces the weight of components, contributing to fuel efficiency and improved performance in aerospace applications.

- By the end of 2023, it is estimated that over 50% of industrial companies will have incorporated 3D printing for prototyping and low-volume production purposes. This adoption is driven by the benefits of faster and cost-effective prototyping, as well as the ability to produce small batches of customized products.

- The field of 3D printing continues to see significant innovation, as reflected in the projected 20% increase in the number of global patents filed in 2023. This demonstrates the ongoing efforts to advance the technology and explore new possibilities for its application.

- In the construction industry, the adoption of 3D printing is expected to grow by 40% in 2023. Construction companies are exploring new techniques to utilize 3D printing for building components and structures, offering advantages such as reduced labor costs, faster construction times, and design flexibility.

- Educational institutions are also embracing 3D printing technology, with over 60% projected to implement it for teaching and research purposes by the end of 2023. This enables students and researchers to gain hands-on experience with 3D printing, fostering innovation and creativity in various fields.

- The fashion industry is experiencing a surge in the use of 3D printing, with a projected growth rate of 30% in 2023. Designers are leveraging the technology to explore new possibilities for customized and innovative designs, pushing the boundaries of traditional fashion production.

- Similarly, the jewelry industry is expected to see a significant increase in the use of 3D printing, with a projected growth rate of 35% in 2023. Jewelry designers are utilizing 3D printing to create intricate and customized designs, enabling unique and personalized pieces.

Use Cases and Applications

- Prototyping: 3D printing is widely used for rapid prototyping, allowing designers and engineers to quickly create physical models and test their designs before moving on to production. This saves time and cost compared to traditional prototyping methods.

- Manufacturing and Production: 3D printing is increasingly being utilized for small-scale manufacturing and production of customized or low-volume parts. It enables the production of complex geometries and reduces the need for assembly, resulting in streamlined manufacturing processes.

- Healthcare and Medical: The healthcare industry has seen significant advancements with 3D printing. It is used to create patient-specific anatomical models for surgical planning, medical implants, prosthetics, and customized medical devices. 3D printing also enables the development of pharmaceuticals with personalized dosages.

- Aerospace and Defense: 3D printing is extensively used in the aerospace and defense sectors for producing lightweight and complex parts, reducing weight and enhancing fuel efficiency. It enables the creation of intricate designs, such as aircraft components, engine parts, and drones.

- Automotive: The automotive industry benefits from 3D printing for rapid prototyping, tooling, and creating customized parts. It allows for the production of lightweight components, improving fuel efficiency and performance. 3D printing is also used for producing spare parts and accessories.

- Architecture and Construction: 3D printing is revolutionizing the construction industry by enabling the creation of complex architectural models, building components, and even entire structures. It offers the potential for cost-effective and sustainable construction methods.

Emerging Trends

Emerging trends in the 3D printing industry reflect its dynamic and innovative nature, as well as its expanding influence across various sectors. The following trends are particularly noteworthy due to their potential to shape the future of manufacturing, healthcare, and technology:

- Increased Use of Sustainable Materials: The growth of the market can be attributed to a heightened focus on sustainability. There’s a shift towards using eco-friendly materials in 3D printing, such as bioplastics and recycled materials. This not only reduces waste but also aligns with global environmental goals.

- Expansion into Healthcare: 3D printing is set to revolutionize the healthcare industry by enhancing the production of custom-made prosthetics, dental implants, and even bioprinting human tissues for transplantation. This customization can lead to better patient outcomes and more efficient medical procedures.

- Advancements in Metal Printing: Metal 3D printing is evolving rapidly, offering new possibilities for industries such as aerospace, automotive, and manufacturing. The ability to print complex metal parts quickly and cost-effectively can significantly reduce production times and costs.

- Integration of AI and Machine Learning: Artificial intelligence (AI) and machine learning are being integrated into 3D printing processes to optimize designs, improve material properties, and streamline production workflows. This integration can lead to smarter manufacturing processes and enhanced product quality.

- Greater Accessibility and Affordability: As 3D printing technology becomes more accessible and affordable, it opens up opportunities for small businesses and individual enthusiasts. This democratization of manufacturing can spur innovation and creativity across various fields.

- Mass Customization: The ability to customize products en masse without significant cost increases is a game-changer for industries such as consumer goods, fashion, and automotive. This trend could lead to more personalized products, meeting specific customer needs and preferences.

- Construction and Architecture: The use of 3D printing in construction and architecture is emerging, with the potential to build structures quickly and with less waste. This can lead to more sustainable building practices and innovative architectural designs.

Key Players Analysis

The 3D printing market is characterized by a dynamic and competitive environment, with several key players driving innovation and growth. These companies play pivotal roles in shaping the industry through their contributions to technology development, material advancement, and application expansion. Here’s an overview of the top key players in the 3D printing market:

- Stratasys Ltd: Renowned for its pioneering contributions to the 3D printing industry, Stratasys specializes in the development of 3D printing equipment and materials. Their solutions cater to a wide range of industries, including automotive, healthcare, aerospace, and education, offering both prototyping and manufacturing solutions.

- Materialise: Materialise stands out for its software solutions that enhance the 3D printing process, alongside providing 3D printing services. Their focus on medical and industrial applications has made significant contributions to custom medical implants and additive manufacturing innovations.

- EnvisionTec Inc: A leader in the digital light processing (DLP) technology segment, EnvisionTec offers a wide array of 3D printers that serve industries like jewelry, dental, and biofabrication, known for their high precision and surface finish.

- 3D Systems Inc: As one of the original innovators in the 3D printing space, 3D Systems provides comprehensive 3D products and services, including printers, print materials, parts services, and digital design tools, supporting a variety of industries from healthcare to aerospace.

- GE Additive: A part of General Electric, GE Additive focuses on transforming the aerospace and automotive industries through additive manufacturing. They offer metal 3D printers, materials, and engineering solutions that aim to revolutionize industrial manufacturing processes.

- Autodesk Inc: While Autodesk is widely recognized for its software for designers and engineers, it also plays a significant role in the 3D printing industry by providing software that supports 3D design, engineering, and entertainment software.

- Made In Space: Specializing in the unique niche of zero-gravity 3D printing, Made In Space develops technology for space exploration and in-space manufacturing, contributing to the future of off-Earth manufacturing and living.

- Canon Inc: Canon has ventured into the 3D printing market, leveraging its expertise in imaging and optical products to develop 3D printers that promise high precision and reliability, aiming to expand its footprint in the manufacturing sector.

- Voxeljet AG: Voxeljet specializes in large-format 3D printers and on-demand parts services for industrial and commercial customers. Their technology is well-suited for producing complex molds and models, especially for the automotive and aviation industries.

Recent Developments

- January 2023: Meta acquired Luxexcel, a 3D printed optics company, to advance development of their AR glasses

- Early 2023: Nikon completed its acquisition of SLM Solutions, continuing the trend of consolidation in the industry

- In 2023, Formlabs launched its Automation Ecosystem, a suite of products designed to improve 3D printing workflow

Conclusion

In conclusion, the global 3D printing market is experiencing robust growth and is projected to reach USD 135.4 billion by 2033, with a CAGR of 21.2%. The increasing adoption across various industries, advancements in materials, and cost-effectiveness are driving market expansion. However, challenges related to high initial investment and limitations in print speed and quality need to be addressed. With ongoing developments and integration with other technologies, the 3D printing market holds enormous potential for transforming manufacturing and unlocking new possibilities in the years to come.