Table of Contents

Introduction

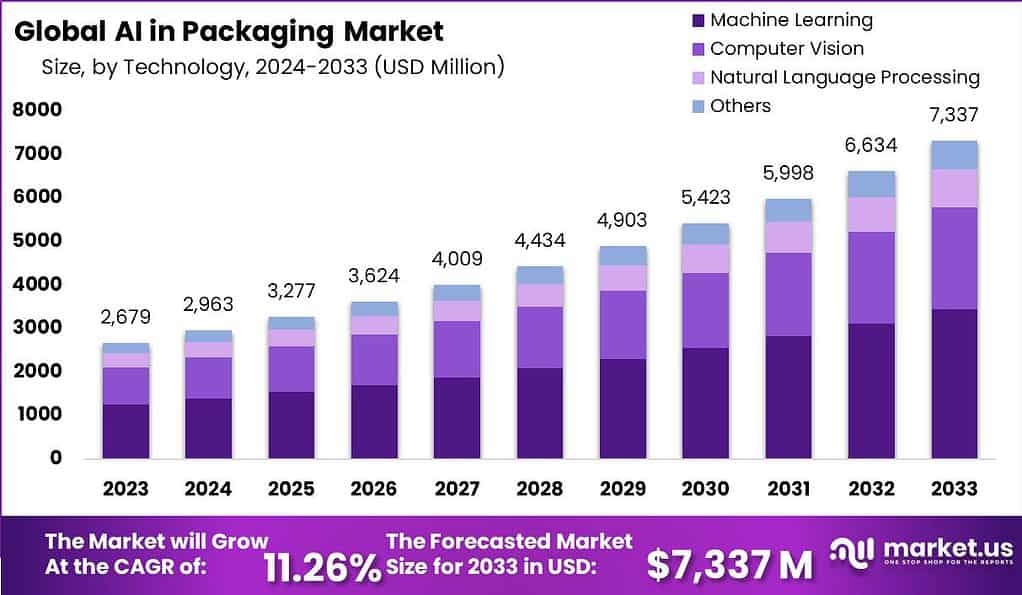

The global AI in packaging market is expected to experience significant growth, expanding from USD 2,679 million in 2023 to around USD 7,337 million by 2033. This represents a compound annual growth rate (CAGR) of 11.26% during the forecast period from 2024 to 2033. The growth is driven by the integration of artificial intelligence (AI) technologies in packaging operations, which enhance efficiency, reduce labor costs, and improve operational efficiency through automation and robotics for tasks such as picking, packaging, palletizing, and sorting.

AI is optimizing various components of the packaging supply chain, including inventory control, logistics, and route optimization. By analyzing vast amounts of data, AI identifies inefficiencies, predicts demand changes, and streamlines processes. The market is shifting towards machine learning technologies and quality control, with these segments expected to grow at CAGRs of approximately 29.5% and 29%, respectively, through 2034.

Countries such as India, Canada, and Japan are forecasted to experience high CAGRs of 39.5%, 32%, and 34%, respectively, through 2034, owing to the rapid adoption of advanced technologies in several industries, including food and beverage, pharmaceuticals, and consumer products.

Moreover, the global packaging market is set to cross by USD 265 billion at a CAGR of 4.29% between 2023 and 2028. This growth is driven by the need for innovative packaging solutions that attract consumers through visual appeal and brand differentiation. The demand for tamper-proof packaging is also emerging as a key trend, maintaining product integrity across several industries, including food, beverage, and healthcare.

The AI in the packaging sector has been witnessing significant M&A activity with companies prioritizing scaling or expanding business, geographic expansion, and growing product portfolios through strategic acquisitions. According to research, the packaging sector completed 297 M&A deals in 2023, totaling a value of over USD 27 billion. A highlight of the year was Smurfit Kappa’s acquisition of WestRock for USD 19.9 billion, aiming to create a leading global platform and offer a comprehensive range of packaging solutions. This merger, slated for completion in December 2024, reflects the industry’s focus on building global platforms that enhance customer offerings.

The United States emerged as a dominant player in the M&A landscape, leading with 96 deals valued at USD 13.3 billion, significantly ahead of other countries in terms of deal volume and value. This activity emphasizes the competitive edge and strategic positioning of U.S. companies in the global packaging market.

Key Takeaways

- The global AI in the Packaging Market is projected to grow at a robust CAGR of 11.26% from 2024 to 2033.

- The market size of AI in the Packaging industry is anticipated to reach USD 7,337 million by 2033.

- In 2023, the AI in Packaging market was valued at USD 2,679 million.

- The Machine Learning segment accounted for over 47% of the market share in 2023.

- Packaging Design and Customization held more than a 33% share of the market in 2023.

- The Food & Beverage sector captured over 29% of the market share in 2023.

- North America dominated the AI in Packaging market with over 38% market share in 2023.

- North America’s demand for AI in Packaging was valued at USD 1,018 million in 2023.

- Significant players in the AI in Packaging market include SIG Combibloc, Appetite Creative, GreyScale AI, PackageX Inc., Stora Enso, Amcor Plc, Constantia Flexibles GmbH, Sonoco Products Company, Honeywell International Inc, and Winpak Ltd.

To learn more about this report – request a sample report PDF

AI in Packaging Statistics

- The first robotics patent, filed by George Devol in 1954 and granted in 1961, marked a pivotal moment in the packaging industry’s history, with the first industrial robot introduced by his company, Unimation, in 1956, capable of moving packaging material about a dozen feet.

- Over the past six decades, robotics has become integral to the packaging industry, enhancing efficiency and precision across various sectors.

- Artificial Intelligence (AI) is driving the next phase of evolution in the packaging industry, responding to market demands for eco-friendly materials, sustainable consumer goods, and a circular economy.

- The adoption of AI technology, particularly machine learning, streamlines business processes and workflows, accelerating decision-making from months to minutes.

- For instance, a webinar featuring Fabio di Memmo from Aptargroup & Monolith CEO Richard Ahlfeld highlights the transformative impact of Monolith’s no-code AI platform for packaging.

- AI solutions in the packaging industry are diverse, addressing specific business needs and challenges.

- AI-powered vision systems for packaging inspection contribute to sustainability efforts, with algorithms reducing waste and shipment damage by 24%, while also cutting shipping costs by 5%.

- A case study of Packaging Distributors of America (PDA) illustrates how implementing AI led to 100% accuracy in package inspection and a reduction in customer complaints to zero.

- Machine Learning applications extend to date labeling, ensuring accuracy and standardized procedures, consequently reducing errors and improving process efficiencies.

- Tesco’s adoption of data-embedded barcodes for date labeling enhances food traceability and reduces waste, demonstrating the practical application of AI in the packaging sector.

- AI-based recycling systems, exemplified by AMP Robotics’ Cortex, are poised to revolutionize recycling processes for containers, paper, plastic, and other consumer packaging materials.

- With only 16% of the world’s garbage being recycled, there’s significant potential for AI-driven solutions to address ecological concerns and improve recycling rates.

- The European Union estimates that over 80% of product-related environmental impacts are determined during the design phase, underscoring the importance of eco-friendly product engineering.

- Monolith AI stands out as a provider of AI solutions for product development optimization, assisting manufacturers in creating sustainable packaging designs without compromising quality.

- Leading companies like L’Oreal and Aptar leverage Monolith AI to develop sustainable packaging solutions and predict design performance accurately.

- As the sole AI provider for product engineering in the packaging industry, Monolith believes that AI and humans will collaborate to drive innovation and efficiency.

- While AI enhances processes and reduces errors, it is seen as a tool to assist rather than replace human involvement in the packaging industry’s future.

- The growing e-commerce market relies heavily on efficient packaging solutions, creating opportunities for AI-driven innovations to meet evolving consumer demands.

- Companies seeking AI solutions in the packaging industry prioritize addressing pain points such as process inefficiencies, standardization, and waste reduction.

Use Cases

- Recycling Optimization: A significant development is the deployment of AI in recycling efforts. For example, the Carlton Council of North America and AMP Robotics have collaborated to develop Clarke, an AI-powered robot designed to improve the sorting process of recyclables such as cartons, plastic bottles, and containers. Clarke can identify 150 types of cartons and operates with greater efficiency than human workers, significantly impacting the recycling workflow.

- AI for Quality Inspection and Date Labeling: AI-powered vision systems are revolutionizing quality inspection processes in packaging. These systems can perform tasks ranging from anomaly detection to ensuring accuracy in date labeling, significantly reducing manual errors and enhancing operational efficiencies. An instance where AI made a notable impact is a Packaging Distributors of America (PDA) client’s adoption of AI-powered cameras, which led to the elimination of customer complaints related to packaging accuracy.

- Smart Packaging Solutions: AI is driving the evolution of smart packaging solutions that personalize customer interactions and experiences. These solutions utilize data from digital interactions and smart features within the packaging to offer customized products and improve customer engagement. For example, SIG’s Connected Pack solutions are pioneering this approach by personalizing content based on scanning a pack, thereby enhancing the customer experience.

- Sustainability Initiatives: AI’s application in packaging extends to sustainability efforts, aiming to reduce environmental impact. Amazon’s use of AI to minimize packaging waste exemplifies this, with their Packaging Decision Engine optimizing packaging choices based on product attributes and customer feedback. This initiative has contributed to a significant reduction in the company’s use of packaging material.

- Efficiency in Fulfillment Operations: Amazon leverages AI to identify damaged goods in fulfillment centers, preventing waste by ensuring only quality products are shipped to customers. This AI solution is more effective than manual checks and plays a critical role in rerouting items that can be resold at reduced prices, donated, or reused, thus contributing to waste reduction.

- Reducing Food Waste: AI solutions are being deployed in Amazon Fresh grocery stores to monitor shelf life and quality of fruits and vegetables. By analyzing crate images for visual imperfections, this technology aids in recycling usable produce, demonstrating AI’s potential to significantly reduce food waste.

Key Players Analysis

SIG Combibloc

SIG Combibloc is recognized as a leading adopter of Artificial Intelligence (AI) within the packaging industry. The company is leveraging AI to automate repetitive tasks and free up human workers for more complex roles, thereby enhancing efficiency and productivity. Machine Learning (ML) and Computer Vision (CV) are among the AI technologies SIG Combibloc is investing in, particularly for predictive maintenance and automated visual inspections.

Appetite Creative

Appetite Creative leverages AI to enhance connected packaging, focusing on optimizing shipping routes, inventory management, and ensuring product quality through AI-driven analysis. This approach significantly improves the efficiency of deliveries and production processes by detecting defects early.

GreyScale AI

GreyScale AI specializes in improving the safety and quality of packaged goods through advanced technology. Their solutions combine high-resolution X-ray imaging with sophisticated AI algorithms to enhance product inspection accuracy. This approach is supported by cloud-based data analytics, offering a comprehensive view of food safety and production data in real time. Their service model includes continuous machine monitoring and software updates, ensuring the highest standards of inspection are maintained

PackageX, Inc.

PackageX, Inc. is revolutionizing logistics with its AI-driven cloud platform that automates logistics operations for efficiency and visibility. Their technology, trained by over 20 million labels, price tags, and license plates, utilizes OCR, Barcode, and QR code scanning. This enhances accuracy and drives efficiency across the logistics sector, making it a transformative tool for global logistics

Stora Enso

Stora Enso, recognized for its leadership in renewable packaging, is advancing the packaging design process through AI. Their focus is on making packaging design selection efficient by creating a digital collaboration platform that utilizes intelligent technologies. This platform aims to streamline the buying process, enabling easier access to Stora Enso’s vast packaging design catalog through advanced search algorithms and deep learning

Amcor Plc

Amcor recently announced its Amcor Lift-Off winner, Greyparrot, an AI-generated waste analytics company. Greyparrot is set to receive a $500,000 investment and access to Amcor’s expertise in sustainability and packaging. This partnership highlights Amcor’s commitment to advancing responsible packaging solutions through AI technology.

Constantia Flexibles GmbH

Constantia Flexibles is a global leader in flexible packaging, focusing on sustainability and innovative solutions. The company emphasizes packaging with the highest benefit at the lowest environmental impact, working towards more sustainable and recyclable packaging solutions. Constantia Flexibles is dedicated to increasing the sustainability of its packaging to not only save environmental resources but also to align with modern consumer preferences for eco-friendly products.

Sonoco Products Company

Sonoco Products Company, with a history dating back to 1899, operates globally with over 330 plants in more than 85 nations. The company is known for its focus on sustainability, aiming to create eco-friendly solutions across various markets. Sonoco takes pride in offering packaging that not only meets consumer needs but also addresses environmental challenges.

Honeywell International, Inc.

Honeywell has launched a new robotic technology aimed at enhancing productivity and reducing injuries within warehouses and distribution centers. This innovation utilizes machine learning and advanced gripping technologies to automate the process of unloading pallets, minimizing the need for manual labor and addressing labor shortages. The Smart Flexible Depalletizer, showcased at PACK EXPO, represents a significant advancement in warehouse automation by eliminating the need for pre-programming or operator intervention.

Winpak Ltd.

Winpak Ltd. is recognized for its pioneering work in AI-driven packaging solutions. The company integrates machine learning for enhanced quality assurance, employs AI for predictive maintenance of packaging machines, and optimizes its supply chain with AI algorithms. This integration of AI not only improves efficiency and productivity but also aligns with ethical considerations in AI use, including data privacy and bias mitigation.

Conclusion

The integration of AI technologies is poised to significantly influence the packaging market, offering innovative solutions to enhance operational efficiency, supply chain management, and quality control. The expansion of e-commerce and evolving consumer preferences towards sustainable and tamper-proof packaging further contribute to the dynamic growth of this market.