Table of Contents

Introduction

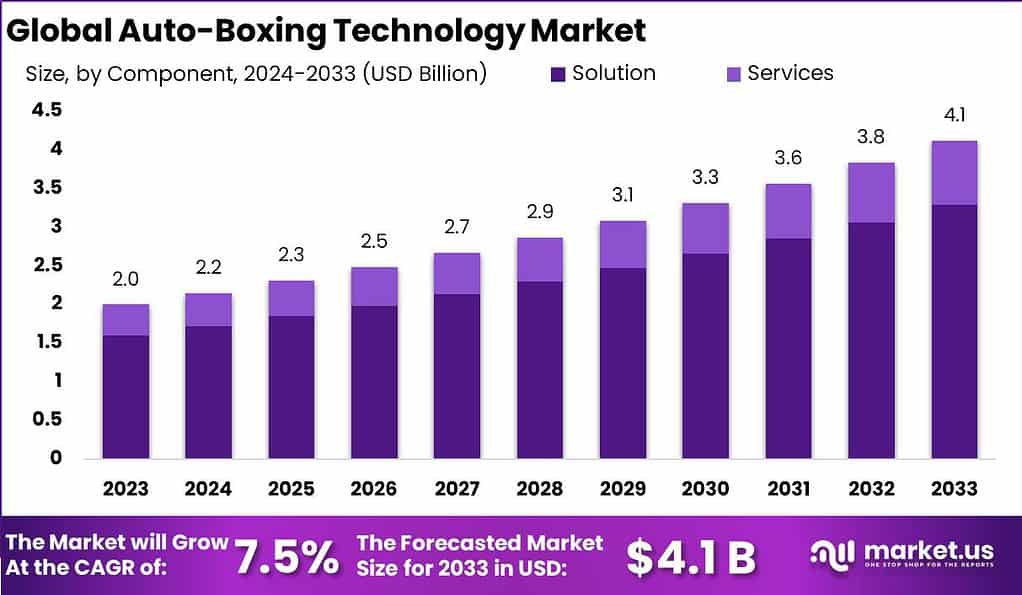

The Auto-boxing Technology Market is poised for significant growth, with an estimated worth of around USD 4.1 billion by 2033, showcasing a robust Compound Annual Growth Rate (CAGR) of 7.5% over the forecast period from 2024 to 2033. Auto-boxing technology revolutionizes packaging processes by employing advanced systems that can adapt to diverse product sizes and shapes with minimal human intervention. These systems utilize sensors and adjustable components to accurately measure and configure the appropriate box size for each item, ensuring secure packaging during transit. This technology accelerates the packaging process, minimizes material wastage, and enhances overall efficiency on the packing line.

The market for auto-boxing technology is witnessing rapid expansion, driven primarily by the escalating demands of the e-commerce sector. The surge in online shopping necessitates swift and efficient packaging solutions capable of handling high-volume orders and varied product types. Additionally, the push to reduce labor costs and streamline supply chain operations further propels market growth. Innovations in auto-boxing technology continuously focus on improving packaging speed, accuracy, and adaptability to cater to a wider array of products.

Auto-boxing technology offers unparalleled flexibility and adaptability in packaging operations, as systems can be programmed to accommodate various product specifications without manual adjustments. This versatility is particularly advantageous for industries with diverse product portfolios or those experiencing frequent changes in packaging requirements. Moreover, these systems contribute to sustainability efforts by optimizing box sizes based on product dimensions, thus minimizing packaging material and reducing carbon emissions associated with transportation.

To learn more about this report – request a sample report PDF

Auto-boxing Technology Statistics

- The global auto-boxing technology market is expected to grow significantly, with its value rising from USD 2.0 billion in 2023 to about USD 4.1 billion by 2033.

- This growth represents a compound annual growth rate (CAGR) of 7.5% from 2024 to 2033.

- The Solution segment held a dominant position in the auto-boxing technology market, capturing over 80% of the market share in 2023.

- In 2023, the Food segment captured more than 26.5% of the market share.

- The APAC region held a leading market position in 2023, with more than 36.5% of the market share.

- Projected Market Growth: The U.S. auto-boxing technology market is expected to grow at a Compound Annual Growth Rate (CAGR) of 7.1% from 2024 to 2030. Prominent companies like Packsize International, Inc. and WestRock Company are contributing to this growth.

- Rise of B2B E-commerce: The International Trade Administration (ITA) predicts a significant increase in the Gross Merchandise Value (GMV) of global Business-to-business (B2B) e-commerce. It is estimated to grow from USD 24,453 billion in 2023 to USD 36,163 billion in 2026.

- High Production Capacities: Notable auto-boxing technology solutions like CMC Packaging Automation’s CMC Genesys and Packsize International, Inc.’s X7 box-making machine have impressive production capacities. The CMC Genesys can produce up to 850 boxes per hour, while the X7 machine can produce up to 1,020 boxes per hour. This capability is crucial to meet the growing demand for fast delivery times in the e-commerce sector.

- Labor Cost Considerations: Labor costs are a significant factor driving the adoption of auto-boxing technology. According to the International Labour Organization (ILO), the hourly labor costs in the U.S. were USD 40.23 in 2022, while in Canada, they were USD 32.74 in 2021. By automating the packaging process, businesses can reduce labor costs and improve efficiency.

Emerging Trends

- Increased Automation and Efficiency: The demand for faster, more efficient packaging solutions is driving the integration of advanced automation in auto-boxing technologies. This trend is crucial in minimizing dependency on the workforce and enhancing operational efficiency.

- Customization and Flexibility: Innovations in auto-boxing systems are allowing for more flexible and customized packaging solutions. These advancements cater to the growing need for tailored packaging, which can efficiently adapt to various product sizes and shapes.

- Growth in E-commerce: As online shopping continues to expand, the need for efficient packaging solutions that can handle high volumes of orders is becoming increasingly important. Auto-boxing technology supports this by producing custom-sized boxes quickly to meet the rapid pace of e-commerce.

- Environmental Sustainability: There is a growing emphasis on reducing waste and enhancing sustainability in packaging. Auto-boxing technology helps in reducing material waste by creating right-sized packaging, thus supporting environmental sustainability initiatives.

- Technological Integration: The integration of technologies like intelligent software and IoT within auto-boxing systems is becoming more prevalent. These technologies enhance the capability of packaging systems to optimize materials and operational efficiency.

Top Use Cases of Auto-Boxing Technology

- Retail and E-commerce: Auto-boxing is extensively used in the retail and e-commerce sectors to handle large volumes of shipping orders efficiently. The technology allows for the quick production of customized packaging, which is essential for meeting the demands of online consumers.

- Food Industry: In the food sector, auto-boxing technology is critical for ensuring food safety and regulatory compliance. The technology minimizes human contact during packaging, which is vital for maintaining hygiene and preventing contamination.

- Pharmaceuticals: Auto-boxing plays a key role in the pharmaceutical industry by providing secure and reliable packaging solutions that protect sensitive products during shipping and handling.

- Manufacturing: For manufacturers, auto-boxing technology facilitates the efficient packaging of manufactured goods, enabling quicker dispatch and better handling of products throughout the supply chain.

- Sustainable Packaging Initiatives: Companies aiming to reduce their environmental impact are adopting auto-boxing solutions to minimize packaging waste and improve sustainability. This use case is increasingly relevant as businesses face pressure to adopt greener practices.

Major Challenges

- Labor Shortage: The auto-boxing industry is partially driven by the need to address labor shortages within the packaging sector. Automating boxing processes minimizes dependency on the workforce, which is critical as industries face persistent labor challenges.

- High Operational Costs: Maintaining cost efficiency in operations is a significant challenge. The high cost of implementing advanced auto-boxing technologies can be a barrier for some businesses, despite the long-term savings on labor and materials.

- Technical Complexity: The integration of advanced auto-boxing systems can be technically complex, requiring significant training and technical support. This complexity can hinder adoption for companies without the necessary technical expertise.

- Regulatory Compliance: Ensuring compliance with various international and regional regulations regarding packaging standards and waste management can complicate the deployment and operation of auto-boxing technologies.

- Supply Chain Integration: Fully integrating auto-boxing systems within existing supply chain operations can be challenging. Companies need to ensure that these automated systems sync well with other logistics and supply chain management systems without disrupting existing operations.

Market Opportunities

- E-commerce Growth: The continued expansion of e-commerce globally presents a significant opportunity for the auto-boxing technology market. The demand for efficient, scalable packaging solutions that can handle high volumes of shipments is increasingly critical.

- Sustainability Initiatives: There is a growing emphasis on sustainability in packaging. Auto-boxing technology helps in reducing material wastage and improving the sustainability of packaging processes by creating custom-sized boxes that fit the product perfectly, thus minimizing waste.

- Technological Advancements: Innovations in machine learning and automation are enhancing the capabilities of auto-boxing technologies, making them more efficient and adaptable to various product types. This technological progression opens new applications in different sectors.

- Global Manufacturing Shifts: As manufacturing sectors in various regions seek more efficient and cost-effective packaging solutions, the auto-boxing technology market is set to benefit. Regions with growing manufacturing activities, particularly in Asia and Europe, present expansive opportunities.

- Customization Needs: The trend towards personalized packaging in sectors such as retail and consumer goods is rising. Auto-boxing technologies that can offer on-demand packaging customization are well-positioned to capitalize on this trend, providing more value to businesses looking to enhance customer experience.

Recent Developments

- Inauguration of Tech Centers: CMC Packaging Automation North America recently inaugurated a 30,000-square-foot Tech Center in Georgia, U.S. This facility aims to foster experimentation, innovation, and collaboration within the industry. By investing in research and development infrastructure, companies like CMC Packaging Automation demonstrate their commitment to advancing technology and sustainability in packaging solutions.

- Introduction of Advanced On-Demand Box Machines: Packsize unveiled the Ultra5, an advanced on-demand box machine developed in collaboration with Walmart. This innovative machine efficiently produces right-sized boxes, aligning with Walmart’s initiative to enhance e-commerce fulfillment, reduce waste, and improve shipping logistics. Such collaborations drive technological advancements and promote eco-friendly packaging practices.

Conclusion

In conclusion, the auto-boxing technology market is witnessing significant growth and transformation in response to the increasing demand for automated packaging solutions in various industries. Auto-boxing technology offers advantages such as improved efficiency, reduced labor costs, and enhanced productivity, making it a preferred choice for businesses seeking to streamline their packaging processes. The market is being driven by factors like the rising e-commerce industry, the need for faster order fulfillment, and the desire for sustainable packaging solutions. Key players in the market are investing in research and development to introduce innovative and advanced auto-boxing systems that can cater to the evolving needs of different sectors.