Table of Contents

Introduction

Laser displacement sensors are precision measurement devices that utilize laser technology to determine the distance between the sensor and a target object. These sensors project a laser beam onto the surface of the object, and based on the reflection or the time it takes for the light to return, they calculate the distance with high accuracy. They are favored in industrial settings for their non-contact, high-speed capabilities, which allow for measurements on moving or delicate objects without causing any damage.

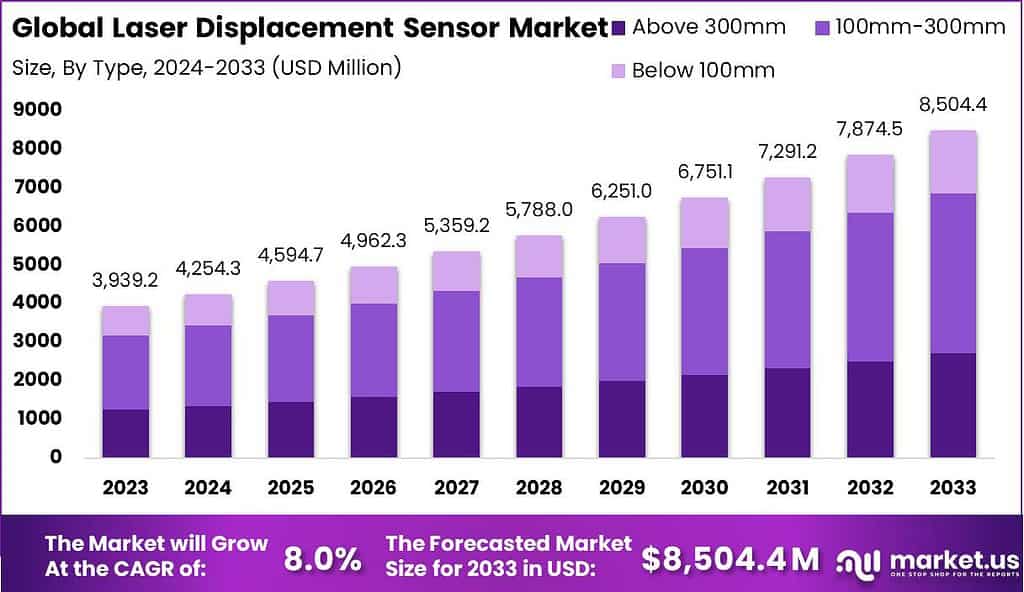

According to Market.us, The Global Laser Displacement Sensor Market is projected to reach a valuation of approximately USD 8,504.4 Million by 2033, up from USD 3,939.2 Million in 2023. This represents a compound annual growth rate (CAGR) of 8.0% over the forecast period from 2024 to 2033.

The laser displacement sensor market is experiencing significant growth due to their increasing adoption in automated manufacturing, quality control, and robotics. Industries such as automotive, electronics, and aerospace extensively utilize these sensors to enhance precision in production lines and ensure product quality. Technological advancements are continually improving the speed, accuracy, and range of these sensors, expanding their applications.

The market is also driven by trends towards automation and smart manufacturing processes, where precise measurements are crucial. As industries continue to innovate and adopt more sophisticated manufacturing techniques, the demand for laser displacement sensors is expected to rise, promising a robust market expansion.

However, the market faces challenges, primarily related to the high cost of advanced sensor technologies and the need for significant initial investments in automation infrastructure. Additionally, the precision required in complex applications poses a technical challenge in terms of sensor design and integration. Despite these challenges, there are substantial opportunities in the market.

The ongoing shift towards Industry 4.0 and the integration of IoT in industrial operations open up new avenues for the application of laser displacement sensors. Moreover, emerging markets are increasingly investing in automation technologies, presenting further opportunities for expansion in these regions. The ability of these sensors to contribute to enhanced efficiency and productivity makes them a valuable component in the future of manufacturing and quality control.

Laser Displacement Sensor Statistics

- The market size for laser displacement sensors is anticipated to grow from USD 3,939.2 Million in 2023 to USD 8,504.4 Million by 2033. This reflects a compound annual growth rate (CAGR) of 8.0% over the forecast period from 2024 to 2033.

- In the segmental analysis for 2023, the range of 100mm-300mm was the predominant category, capturing a significant market share of 48.9%.

- The segment for sensors with ranges above 300mm also held a robust market share, amounting to 31.9%.

- Sector-wise, the automotive industry was the largest consumer of laser displacement sensors, commanding a dominant share of 33.3%.

- The manufacturing sector also represented a considerable portion of the market, accounting for 23.9% of the total market share.

- Geographically, Asia-Pacific was the leader among the regional markets, holding the highest share of 38.7% and generating revenue of USD 1,524.4 million.

- North America also demonstrated a strong market presence, securing 30.1% of the market share in 2023.

- In the subsequent years, the market is expected to maintain its growth momentum. By 2025, the market is forecasted to expand to USD 4,594.7 million, followed by an increase to USD 4,962.3 million in 2026. The growth trajectory suggests steady demand and expansion in uses and applications of laser displacement sensors.

- By 2027, the market value is projected to reach USD 5,359.2 million. The following year, 2028, will see further growth, with the market expected to rise to USD 5,788.0 million. These figures indicate a continuous appreciation in the value and utility of laser displacement sensors across various industries.

- The growth continues into the next decade, with the market size expected to reach USD 6,251.0 million by 2029, and USD 6,751.1 million by 2030. The consistent increase in market value reflects the ongoing technological advancements and the increasing incorporation of laser displacement sensors in industrial applications.

- The market is projected to achieve a significant milestone by 2033, reaching a total size of USD 8,504.4 million. This growth, at a compound annual growth rate of 8.0%, highlights the significant market opportunities and the robust potential of the laser displacement sensor industry over the coming years.

- Over 60% of laser sensors utilized in automated machinery are based on 2D or 3D technology. This indicates a strong preference for these technologies due to their precision and capability to handle complex measurements and operational environments. These types of sensors are essential in various applications, including positioning, profiling, and dimension measurement, enhancing the efficiency and accuracy of automated systems.

- The United States holds a substantial portion of the laser sensors market in North America, accounting for approximately 25%. This significant share underscores the United States’ role as a critical market for advanced manufacturing technologies, reflecting its advanced industrial base and substantial investments in automation technologies.

Emerging Trends

- Integration with IoT and AI: There is a growing trend to integrate laser displacement sensors with IoT and AI technologies. This integration enhances data analytics capabilities, making it possible to optimize processes and predict maintenance needs in real-time, particularly in industrial automation settings.

- Increased Precision and Miniaturization: Advances in technology are driving the development of more compact and highly precise laser displacement sensors. These improvements are crucial for applications in electronics manufacturing and semiconductor industries, where space constraints and the need for high accuracy are significant.

- Expansion in Various Industries: Laser displacement sensors are being increasingly utilized across a diverse range of industries, including automotive, aerospace, consumer electronics, and healthcare. This is due to their reliability and the precision they bring to critical measuring and monitoring tasks.

- Enhanced Range and Sensitivity: New models of laser displacement sensors are being developed with greater range and sensitivity, enabling their use in more complex and demanding environments. This includes applications in safety and security systems where high precision is essential.

- Energy Efficiency and Cost Reduction: Ongoing research and development are focusing on making laser displacement sensors more energy-efficient and cost-effective. This trend is important for making these technologies accessible to smaller businesses and less industrialized regions, broadening the market reach.

Top Use Cases for Laser Displacement Sensors

- Quality Control in Manufacturing: These sensors are extensively used in the manufacturing sector for quality control processes. They help in ensuring the precision of assembly lines, especially in automotive and electronics manufacturing, by accurately measuring the dimensions and positioning of components.

- Distance Measurement and Monitoring: In construction and engineering, laser displacement sensors are crucial for precise distance measurement and monitoring, aiding in the alignment and placement of large structural components.

- Security and Surveillance: With high-resolution capabilities, these sensors are ideal for security and surveillance applications. They can detect minute changes and movements, making them suitable for perimeter security systems and intrusion detection.

- Healthcare Applications: In healthcare, laser displacement sensors are used for various monitoring applications, including the calibration of medical devices and ensuring the accuracy of robotic surgery instruments.

- Food and Beverage Industry: These sensors play a critical role in the food and beverage industry, helping in the packaging verification process, ensuring proper fill levels, and detecting contaminants, thus maintaining safety and quality standards.

Major Challenges

- High Sensitivity to Environmental Conditions: Laser displacement sensors are affected by various environmental factors such as ambient light, dust, and surface reflectivity, which can interfere with their accuracy and reliability.

- High Initial Costs: The initial investment required for these sensors is relatively high, which can be a barrier for small to medium enterprises looking to integrate these technologies.

- Complex Integration and Maintenance: Integrating laser displacement sensors into existing systems can be challenging and often requires specialized knowledge. They also require regular calibration and maintenance to ensure consistent performance.

- Competition from Alternative Technologies: There is significant competition from other displacement sensing technologies like capacitive or inductive sensors, which may offer advantages in certain applications.

- Market Saturation in Developed Regions: In regions like North America and Europe, the market is nearing saturation, which may limit new opportunities for growth compared to emerging markets in Asia-Pacific.

Market Opportunities

- Automation and Industry 4.0: The growing adoption of automation and smart manufacturing across industries provides a substantial opportunity for the deployment of laser displacement sensors.

- Advancements in IoT and AI: Integrating IoT and AI with laser displacement sensors can enhance their functionality, enabling features like predictive maintenance and automated decision-making.

- Demand in Automotive and Consumer Electronics: These industries require high precision in manufacturing processes, where laser displacement sensors can be significantly beneficial.

- Emerging Markets: Regions like Asia-Pacific are experiencing rapid industrial growth, presenting new opportunities for the adoption of advanced sensing technologies.

- New Applications Beyond Traditional Industries: Expanding into new areas such as healthcare, robotics, and consumer electronics offers potential growth avenues for the market.

Recent Developments

- Cognex Corporation has introduced the In-Sight 3800 vision system in January 2023, which integrates with laser displacement sensors to improve high-speed, accurate measurements in automation applications.

- Banner Engineering announced in March 2023 the release of their new LE550 laser displacement sensor, designed for precise measurement in challenging environments, ensuring accurate and stable performance.

- Panasonic has expanded their sensor technology portfolio with the launch of the HG-C series of laser displacement sensors in April 2023, aimed at providing high precision in compact forms for industrial applications.

- Keyence Corporation released the LK-G5000 series in June 2023, which features high-speed, high-accuracy laser displacement measurement capabilities, further cementing their position in the market.

- Omron introduced their ZX-GT series of laser displacement sensors in May 2023, designed for high precision and reliability in various industrial applications.

- SICK AG launched the OD5000 series of laser displacement sensors in February 2023, which offer high accuracy and reliability for demanding industrial environments

Conclusion

In conclusion, the laser displacement sensor market is driven by the increasing demand for automation, quality control, and precision measurement in industrial processes. Advancements in sensor technology and the push towards smart manufacturing offer opportunities for the growth and expansion of the laser displacement sensor market.

Despite challenges related to integration complexity and cost, the benefits of using laser displacement sensors for accurate measurement and control make them indispensable tools for enhancing productivity and quality in industrial applications. By addressing these challenges and leveraging the opportunities presented by laser displacement sensors, manufacturers can optimize their operations and stay competitive in an increasingly automated and data-driven industrial landscape.