Table of Contents

Introduction

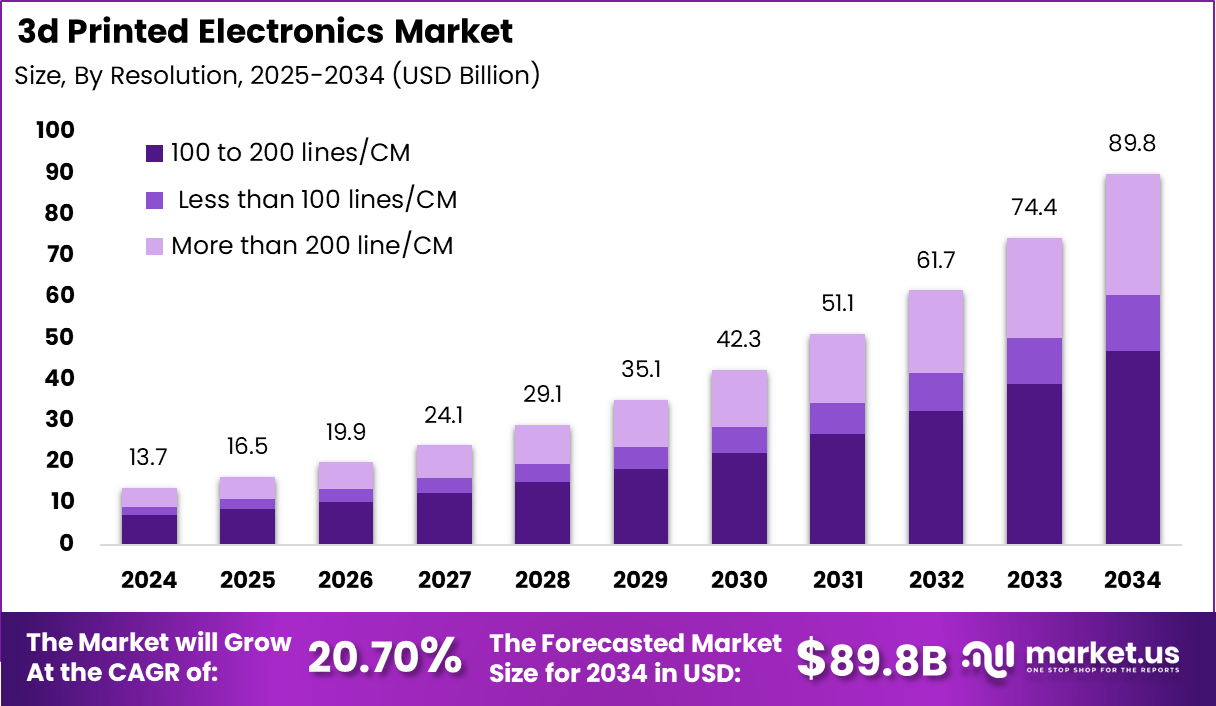

The Global 3D Printed Electronics Market generated USD 13.7 billion in 2024 and is projected to grow from USD 16.5 billion in 2025 to USD 89.8 billion by 2034, achieving a strong CAGR of 20.70%. Growth is fueled by rapid advancements in additive manufacturing, rising demand for flexible electronics, and expanded use in automotive, aerospace, medical devices, and consumer electronics. Asia-Pacific dominated with a 37.8% share, accounting for USD 5.17 billion in 2024, supported by strong manufacturing ecosystems and large-scale technological adoption.

How Growth is Impacting the Economy

The rising adoption of 3D printed electronics positively impacts the global economy by accelerating manufacturing innovation, reducing production waste, and enabling rapid prototyping that shortens product development cycles. These advantages support cost-efficient, localized production, enhancing industrial competitiveness. Economies benefit from increased demand for advanced materials, nanotechnology, and high-performance printing systems.

The shift toward on-demand manufacturing stimulates small- and medium-sized enterprise participation, fostering entrepreneurship and job growth in design, engineering, and digital fabrication. Investments in smart factories further boost automation, improving productivity across electronics, automotive, aerospace, and medical sectors. This transition encourages countries to strengthen their semiconductor and electronics supply chains, reducing import dependency and reinforcing economic stability. Overall, 3D printed electronics contribute to long-term industrial modernization and innovation-led GDP growth.

➤ Smarter strategy starts here! Get the sample – https://market.us/report/3d-printed-electronics-market/free-sample/

Impact on Global Businesses

Rising costs associated with advanced materials, precision printing systems, and supply chain restructuring push global businesses to adopt scalable 3D printing strategies. Supply chains shift toward digital inventories and decentralized production models to avoid delays and reduce logistics complexity. Sector-wise, automotive and aerospace benefit from lightweight components; consumer electronics gain customized circuit designs; and healthcare adopts printed biosensors and wearable electronics for improved diagnostics. Manufacturing agility increases, enabling companies to respond faster to market changes and demand fluctuations.

Strategies for Businesses

- Adopt hybrid additive manufacturing to optimize cost and performance.

- Invest in R&D for conductive inks, substrates, and nanomaterials.

- Build decentralized micro-factories to reduce supply-chain risks.

- Integrate AI-driven design tools for circuit optimization.

- Strengthen partnerships with material suppliers and printing technology firms.

- Focus on sustainability by minimizing production waste.

Key Takeaways

- Market to reach USD 89.8 billion by 2034.

- Strong CAGR of 20.70% through 2025–2034.

- Asia-Pacific leads with 37.8% share.

- Growth driven by flexible, lightweight, and customized electronics.

- Automotive, aerospace, and medical sectors show highest adoption.

➤ Unlock growth secrets! Buy the full report – https://market.us/purchase-report/?report_id=166203

Analyst Viewpoint

The market is experiencing strong upward momentum as industries embrace digitized manufacturing to enhance speed, performance, and customization. Growing adoption of flexible electronics and printed sensors accelerates innovation across consumer and industrial applications. Looking ahead, advancements in multi-material printers, nano-ink formulations, and automated fabrication will further strengthen market expansion. The future remains highly positive, supported by rising demand for on-demand manufacturing, sustainable production, and high-performance printed components that reduce reliance on traditional fabrication methods.

Use Case & Growth Factors

| Category | Details |

|---|---|

| Key Use Cases | Flexible circuits, sensors, antennas, wearables, lightweight components, medical diagnostic devices |

| Growth Factors | Miniaturization trends, Industry 4.0, flexible electronics demand, rapid prototyping, material innovation |

Regional Analysis

Asia-Pacific dominates due to strong electronics manufacturing hubs, high R&D spending, and rapid industrial automation. Countries such as China, Japan, South Korea, and Taiwan lead adoption in printed circuits, sensors, and display technologies. North America shows strong growth driven by aerospace, defense, and medical device innovation. Europe benefits from advanced automotive production and sustainability-driven electronic innovations. Latin America, the Middle East, and Africa will gradually expand adoption as manufacturing modernization and digital transformation accelerate across key industries.

➤ Want more market wisdom? Browse reports –

- RoCE for AI Workloads Market

- Data Contracts for AI Market

- Returns Root Cause AI Market

- Opto Semiconductor Market

Business Opportunities

Significant opportunities exist in advanced conductive inks, nanoparticle materials, high-precision printing systems, and integrated 3D electronics design platforms. Startups can capture value through customized wearable electronics, printed sensors, and medical microdevices. Manufacturers can expand offerings in automotive lightweight electronics, smart packaging, and IoT-enabled components. Consulting and system-integration opportunities rise as industries migrate from traditional circuit manufacturing to agile, on-demand 3D printed production environments.

Key Segmentation

Key segments include printers, materials, conductive inks, substrates, design software, and services. Applications span flexible circuits, sensors, antennas, PCBs, medical diagnostics, aerospace components, and wearable electronics. Deployment environments include industrial manufacturing, R&D laboratories, consumer electronics production, aerospace facilities, automotive plants, and medical device manufacturing. End-users include electronics manufacturers, automotive companies, aerospace firms, medical device producers, research institutions, and packaging and IoT solution providers.

Key Player Analysis

Leading participants focus on improving printing precision, expanding multi-material printing capabilities, and enhancing conductivity performance. Companies prioritize R&D in nanomaterials, ink optimization, and high-speed fabrication to meet volume demands. Strategic initiatives include collaboration with electronics manufacturers, integration with digital design platforms, and the development of scalable production lines. Emphasis is placed on sustainability, repeatability, and quality control to ensure reliability for mission-critical applications across aerospace, healthcare, and automotive industries.

- LG Display Co Ltd

- Samsung Electronics Co. Ltd

- Molex, LLC

- Agfa- Gevaert Group

- E Ink Holdings

- Nova Centrix

- BASF SE

- Nissha Co, Ltd

- DuPont de Nemours, Inc

- Palo Alto Research Center Incorporated

- ISORG SA

- Sumitomo Electric Industries Ltd

- Nano Dimension

- Hensodt

- GSI Technologies LLC

- Enfucell

- Draper

- Eastprint Incorporated

- The Cubbison Company

- KWJ Engineering Incorporated

- Others

Recent Developments

- Launch of next-gen multi-material 3D printers for flexible electronics.

- Development of graphene-based conductive inks for high-performance circuits.

- Expansion of printed sensor production for medical diagnostics.

- Partnerships formed to integrate 3D printed electronics into automotive components.

- Introduction of automated inspection technologies for printed circuitry.

Conclusion

The 3D printed electronics market is expanding rapidly, reshaping global manufacturing through advanced materials, scalability, and design flexibility. With strong adoption across industries, it will remain a critical driver of next-generation electronic innovation.