Table of Contents

Introduction

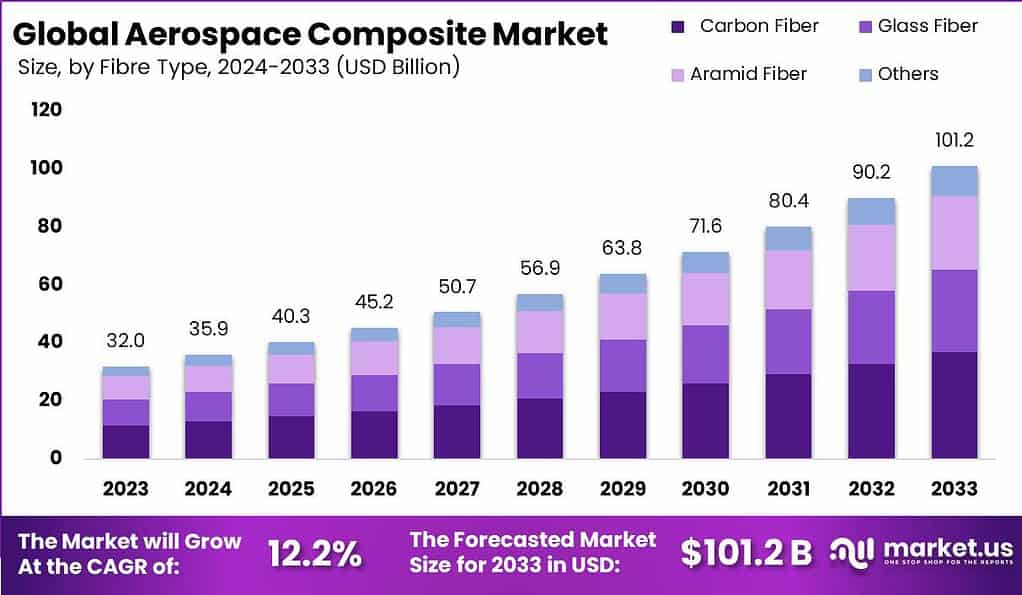

The Aerospace Composites Market is poised for substantial growth, projected to reach USD 101.2 billion by 2033, driven by a robust CAGR of 12.2% throughout the forecast period. These composite materials play a crucial role in aviation by offering lightweight, high-strength solutions crucial for modern aircraft manufacturing.

The aerospace composites market has witnessed significant growth in recent years, driven by various factors and presenting both challenges and opportunities. Aerospace composites refer to materials that are specifically designed and engineered for use in the aerospace industry. These composites offer exceptional strength-to-weight ratios, corrosion resistance, and high thermal stability, making them ideal for applications in aircraft and spacecraft manufacturing.

One of the key growth factors for the aerospace composites market is the increasing demand for lightweight and fuel-efficient aircraft. As airlines strive to reduce operating costs and comply with stringent environmental regulations, there is a growing emphasis on developing aircraft that consume less fuel. Aerospace composites provide a viable solution by significantly reducing the weight of the aircraft, leading to improved fuel efficiency and lower emissions.

However, the market faces challenges, including the high costs associated with the materials and manufacturing processes of aerospace composites. These costs can restrict their use, particularly in sectors where budget constraints are significant. Furthermore, the composites must adhere to stringent regulatory standards that ensure safety and performance, potentially delaying their introduction to the market.

Despite these challenges, the market is ripe with opportunities. Innovations in composite material technology that offer improved resistance to environmental stressors and enhanced lifecycle efficiencies could significantly broaden market prospects. The growing use of composites in military aircraft and space exploration also opens new avenues for expansion. As the aerospace industry seeks to align its operations with environmental sustainability goals, the Aerospace Composites Market is well-positioned for continued growth and innovation.

Aerospace Composites Statistics

- The global Aerospace Composites Market size is estimated to reach USD 101.1 billion in the year 2033, with a CAGR of 12.2% during the forecast period.

- The market was valued at USD 32 billion in the year 2023.

- The Aerospace AI Market size is expected to be worth around USD 34.2 Billion By 2033, growing at a CAGR of 39.8% during the forecast period from 2024 to 2033.

Based on the Component, the Carbon Fibre segment dominated the market, accounting for a 36.5% share in the year 2023. - Based on the Manufacturing Process, the ATL or AFP segment led the market with a 28.5% share in the year 2023.

- Based on the Aircraft type, the Commercial Aircraft segment held the largest market share at 36.7% in the year 2023.

- In 2023, North America held a dominant position in the Aerospace Composites Market, capturing more than a 39% share, with revenues reaching approximately USD 12.4 billion.

- In 2022, the Aerospace Composites industry encountered significant challenges, with demand approaching 2019 levels. By September 2022, domestic traffic levels had returned to 81% of pre-pandemic (2019) levels. The surge in demand was further complicated by labor shortages and escalating supply chain issues.

Emerging Trends

- Increased Adoption in Commercial Aviation: There’s a significant shift towards using composites in commercial aircraft due to their benefits in fuel efficiency and performance enhancement. Commercial airlines are expanding routes and fleet sizes, necessitating more durable and lightweight materials like composites.

- Growth in Military Applications: The military sector is increasingly adopting aerospace composites to modernize their fleets. For example, new manufacturing facilities are being established to produce aircraft that utilize composites, enhancing the capabilities and operational efficiency of military aviation.

- Advancements in Composite Materials: Recent innovations in the field include the development of low-cost carbon fibers and high-performance glass fibers. These materials are being engineered to provide superior strength, reduced weight, and better resistance to environmental factors.

- Expansion in the Asia-Pacific Region: Asia-Pacific is witnessing rapid growth in both civil and military aviation sectors. This growth is driving the demand for advanced composites, with a significant number of new aircraft deliveries expected to use these materials extensively.

- Sustainability Initiatives: There is an increasing focus on sustainability within the aerospace industry, leading to greater use of recyclable and eco-friendly composites. This trend is partly driven by regulatory pressures as well as a shift in industry standards towards more environmentally responsible manufacturing practices.

Top Use Cases for Aerospace Composites

- Structural Components in Aircraft: Aerospace composites are primarily used in critical structural components such as wings, fuselages, and tail assemblies. Their high strength-to-weight ratio significantly enhances aircraft performance and fuel efficiency

- Engine Components: Composites are used in the manufacturing of engine components where high temperature and pressure resistance are crucial. This includes parts like fan blades and casings, which benefit from the material’s lightweight and durability characteristics.

- Interior Applications: Beyond structural elements, composites find extensive applications in aircraft interiors, including seats, overhead bins, and paneling. These applications leverage composites’ aesthetic flexibility and contribute to overall weight reduction.

- Military Drones and Unmanned Vehicles: The use of composites in military drones and other unmanned systems is growing due to the need for lightweight materials that enhance operational range and payload capacity.

- Repair and Overhaul Operations: Composites are increasingly used in the repair and maintenance of older aircraft. Their adaptability and ease of integration with existing materials make them ideal for extending the life of aging aircraft fleets.

Major Challenges

- Supply Chain Disruptions: The aerospace composites industry faces significant challenges due to disruptions in the supply of critical raw materials like titanium, largely influenced by geopolitical tensions, such as the conflict involving Russia.

- High Production Costs: The cost of manufacturing composite structures remains high compared to metallic alternatives. Efforts are ongoing to reduce these costs by adopting technologies from other industries and improving manufacturing processes.

- Labor Shortages: A tight labor market has led to delays in production across the aerospace sector, exacerbated by the slow recovery of commercial aviation post-pandemic.

- Technological Integration Challenges: Integrating advanced manufacturing technologies (Industry 4.0) to increase productivity is crucial but challenging. This includes automating processes and optimizing supply chain management.

- Material Performance Limitations: While composites offer significant benefits like strength and weight reduction, they also face issues like poor interlaminar performance, necessitating ongoing research and development to enhance their properties.

Market Opportunities

- Increased Demand for Fuel Efficiency: The ongoing need to enhance fuel efficiency in aircraft drives the demand for lightweight composite materials, which can significantly reduce aircraft weight and fuel consumption.

- Growth in Military and Defense Applications: The production of military aircraft like the F-35 and the B-21 Raider provides a steady demand for aerospace composites, supported by government defense spending.

- Expansion in Emerging Markets: Rapid industrialization in regions like Asia-Pacific offers substantial growth opportunities for the aerospace composites market, driven by increasing air travel and cargo movements.

- Innovation and Product Development: Continued advancements in composite material technologies and processes offer opportunities for market expansion and penetration into new applications.

- Sustainability Initiatives: With a growing emphasis on sustainability, aerospace composites that contribute to lower emissions and reduced environmental impact are increasingly favored, aligning with global environmental targets.

Recent Developments

- February 2024: Hexcel showcased its latest innovations at JEC World 2024 in Paris, including advancements in carbon fiber and towpreg materials designed for sustainable transport and electric engines. Additionally, Hexcel highlighted the Hopper prosthetic running blade, made from recycled aerospace carbon materials, in collaboration with Airbus and other partners.

- December 2023: Solvay and SGL Carbon entered into a joint development agreement to market composite materials based on large-tow intermediate modulus carbon fiber. This collaboration aims to enhance the competitiveness and performance of aerospace composites.

- December 2023: In collaboration with Solvay, SGL Carbon is working on bringing to market the first composite materials based on large-tow intermediate modulus carbon fiber, enhancing the application of these materials in the aerospace industry.

- December 2023: SGL Carbon, along with Solvay, is developing new large-tow carbon fiber materials to improve the performance of aerospace composites.

Conclusion

In conclusion, the aerospace composites market is experiencing significant growth due to the demand for lightweight, fuel-efficient aircraft and the increasing number of air passengers. However, challenges such as high manufacturing costs and limited recycling options need to be addressed. The market also presents opportunities in the form of electric and hybrid aircraft development and advancements in manufacturing technologies. As the aerospace industry continues to evolve, the adoption of composites is likely to expand, driving further innovation and growth in the market.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)