Table of Contents

Introduction

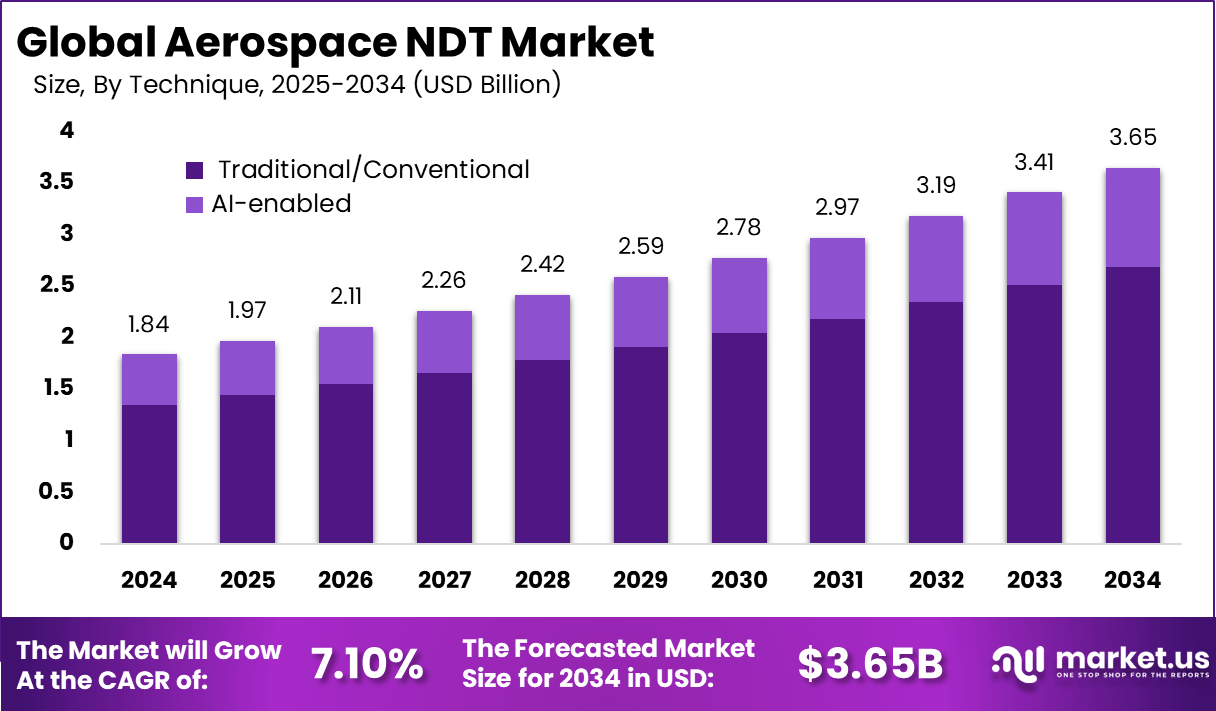

The global aerospace NDT market generated USD 1.84 billion in 2024 and is expected to grow from USD 1.97 billion in 2025 to approximately USD 3.65 billion by 2034, registering a CAGR of 7.10% over the forecast period. In 2024, North America held a dominant position with more than 40.3% market share, accounting for around USD 0.74 billion in revenue, supported by strong aircraft production and maintenance activity.

Aerospace NDT market covers methods to check aircraft parts for flaws without breaking them, using tools like sound waves, X-rays, and magnetic fields to spot cracks or weak spots early. These checks happen during building, fixes, and regular upkeep to keep planes safe under high stress. Recent shifts include drone scans inside fuel tanks and AI that flags issues in real time during tests.

This market plays a crucial role in maintaining safety, reliability, and compliance across the aerospace industry. Aircraft and spacecraft must withstand intense pressures, temperature extremes, and rapid cycles of use, making precise inspection essential. NDT enables inspection of parts like wings, fuselages, engines, and landing gear without disassembly or destruction, helping to prevent failures that could lead to serious safety incidents. This capability contributes directly to operational readiness and regulatory compliance in commercial, military, and space applications.

Key Insights Summary

- Equipment remains the dominant component, contributing 45.2% of overall demand due to sustained investment in advanced inspection hardware used across aerospace production and maintenance.

- Conventional inspection techniques continue to lead with a 73.6% share, supported by their long standing reliability and acceptance in safety critical aerospace applications.

- Ultrasonic testing accounts for nearly 20.8% of inspection usage, reflecting its effectiveness in identifying internal defects in both metallic and composite aerospace structures.

- North America holds approximately 40.3% of total market activity, driven by a strong aerospace manufacturing base, strict safety oversight, and a well established maintenance ecosystem.

- Market momentum is being supported by higher aircraft production, wider use of composite materials, and gradual adoption of automated and digitally enabled inspection systems.

Top Driving Factors

Growth in the aerospace NDT market is driven by increasing air travel demand, expansion of aircraft fleets worldwide, and stricter safety and quality standards. Rising production rates of new aircraft and extended service lives of existing fleets bolster the need for frequent inspections. Additionally, regulatory bodies and manufacturers continually tighten inspection criteria to reduce risk and improve reliability. Digital inspection technologies and automation are also enhancing detection capability and speed, supporting broader adoption of advanced NDT methods.

Demand for NDT in aerospace remains strong across manufacturing and aftermarket service segments. Manufacturers require thorough inspection to validate material integrity and assembly accuracy before aircraft enter service. Operators and maintenance facilities use NDT continuously to monitor structural health over an aircraft’s lifecycle, enabling predictive maintenance programs that reduce unplanned downtime. The industry’s focus on extending aircraft service life without compromising safety further sustains demand for NDT solutions.

Increasing Adoption Technologies

Key technologies supporting adoption include ultrasonic testing, radiographic testing, eddy current inspection, visual inspection, infrared thermography, and phased array ultrasonic testing. Advanced digital methods, such as automated scanning, 3D imaging, and AI-assisted defect recognition, are gaining traction to improve accuracy and throughput. These technologies enable more detailed internal and surface inspections while reducing inspection time and reliance on highly specialised manual techniques.

Organisations adopt aerospace NDT to enhance safety, reduce costly failures, and comply with regulatory standards. NDT detects defects early, allowing corrective actions before issues escalate, which helps prevent accidents and service disruptions. It also supports maintenance planning, reduces unscheduled repairs, and extends component lifecycles. The non-destructive nature of testing preserves component usability, avoiding unnecessary replacements and lowering operating costs.

Investment Opportunities

Investment opportunities exist in advanced NDT technologies, integrated inspection platforms, and service networks supporting aerospace OEMs and MRO (maintenance, repair, overhaul) providers. Demand for portable NDT instruments and automated inspection solutions is rising in response to fleet growth and tighter inspection schedules. There is also potential in AI-enabled analytics, cloud-connected inspection data management, and training services for skilled NDT technicians to support evolving inspection standards.

Aerospace NDT delivers measurable benefits, including greater operational safety, fewer in-service failures, and improved asset reliability. Early defect detection reduces the risk of catastrophic failure and the costs associated with emergency grounding or repairs. NDT also enhances quality assurance processes during manufacturing, supporting consistent product standards and customer confidence. Maintenance facilities benefit from reduced downtime and better planning through predictive inspection data.

Key Market Segments

By Component

- Equipment

- Software

- Services

- Consumables

By Technique

- Traditional/Conventional

- AI-enabled

By Testing Method

- Ultrasonic Testing

- Radiographic Testing

- Magnetic Particle Testing

- Liquid Penetrant Testing

- Visual Inspection Testing

- Eddy-Current Testing

- Acoustic Emission Testing

- Thermography/Infrared Testing

- Computed Tomography Testing

Top Key Players in the Market

- Baker Hughes Company

- Mistras Group Inc.

- SGS SA

- Intertek Group plc

- Applus Services SA

- General Electric Company (GE Aviation NDT Solutions)

- Olympus Corporation

- Nikon Corporation

- Eddyfi Technologies Inc.

- Teledyne Technologies Incorporated

- Zetec Inc.

- Sonatest Ltd.

- TWI Ltd.

- Ashtead Technology Ltd.

- Vermont Ultrasonics Inc.

- YXLON International GmbH

- Hologic Inc. (SureScan)

- Waygate Technologies GmbH

- Magnaflux Corporation

- Fischer Technology Inc.

- Element Materials Technology Group Ltd.

- Collins Aerospace (UTAS NDT Lab)

- Lufthansa Technik AG (NDT Services)

- Airbus S.A.S (AIRTAC NDT)

- Spirit AeroSystems Holdings Inc. (NDT Centers)

- Bombardier Inc. (In-house NDT)

- Others

Future Outlook and Opportunities

The future outlook for the aerospace NDT market remains positive as aircraft production, fleet sizes, and inspection complexity increase. Emerging trends include greater use of automation, digital twins for inspection planning, and AI-driven interpretation of NDT data to support predictive maintenance. As materials such as composites become more prevalent, demand for specialised NDT techniques will grow to address unique inspection challenges. This ongoing technological evolution will expand service offerings and reinforce NDT as an indispensable part of aerospace safety and reliability.

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2024) | USD 1.84 Bn |

| Forecast Revenue (2034) | USD 7.10 Bn |

| CAGR(2025-2034) | 7.10% |

| Base Year for Estimation | 2024 |

| Historic Period | 2020-2023 |

| Forecast Period | 2025-2034 |

Explore More Reports

- Data Acquisition Equipment Market

- RoCE for AI Workloads Market

- Data Contracts for AI Market

- Returns Root Cause AI Market

- Opto Semiconductor Market

- AI Compliance Saas Market

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)