Table of Contents

Introduction

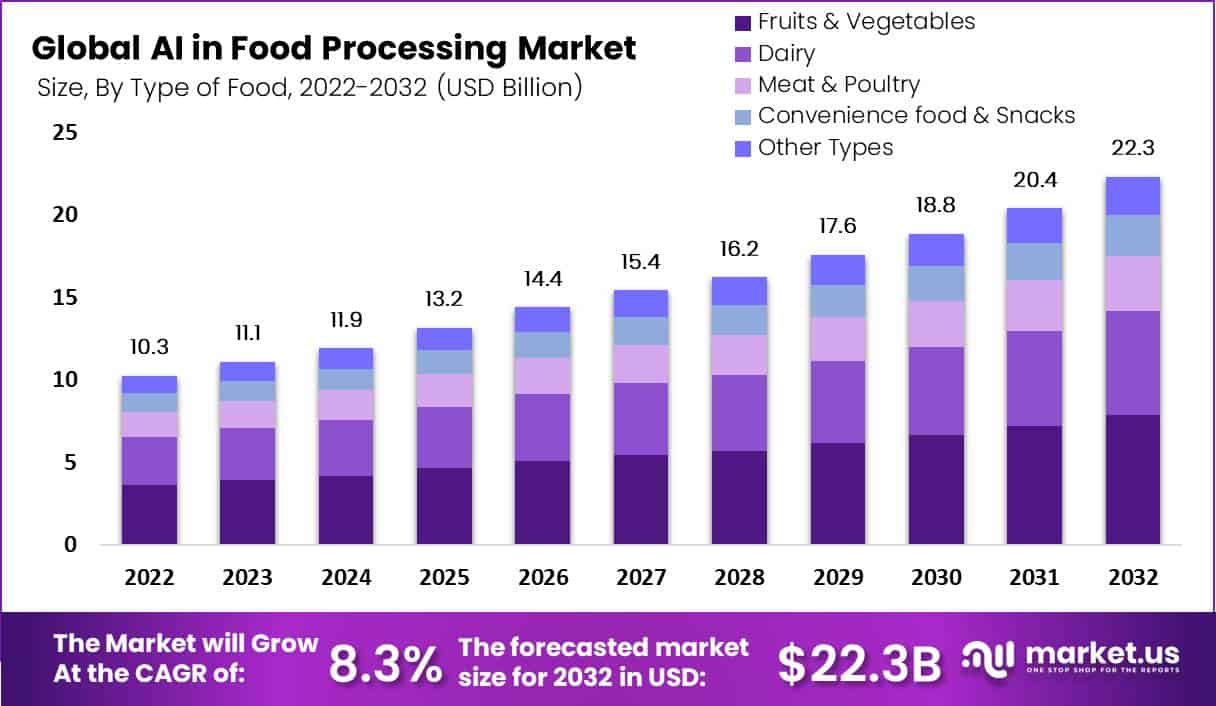

The Global AI in Food Processing Market is projected to grow significantly, reaching a value of USD 22.3 billion by 2032, with a compound annual growth rate (CAGR) of 8.3% from 2023 to 2032. Artificial Intelligence (AI) is reshaping the food processing industry by optimizing production, quality control, and supply chain management. Machine learning, computer vision, and data analytics are key AI technologies being utilized to enhance efficiency, productivity, and safety in food processing operations.

The market for AI in food processing is experiencing substantial growth, driven by the increasing demand for processed foods and the need for supply chain efficiencies amidst global challenges. Market analysts project a continued expansion in this sector, fueled by technological advancements and rising investments in AI capabilities. North America and Europe currently lead in adoption, attributed to their robust technological infrastructure and stringent food safety regulations. The potential for AI in this market is vast, encompassing not only large-scale operations but also small and medium enterprises seeking competitive advantages and innovation.

One of the primary drivers for AI adoption in food processing is the increasing demand for efficient and sustainable food production. With a rising global population, there’s a need to ensure sufficient food supply while minimizing waste and resource usage. AI technologies can optimize processes, reduce energy consumption, and improve yield, contributing to more sustainable food production practices. A notable revelation is that AI-based sensor technology could lead to significant annual savings in energy and water consumption in food processing plants. This emphasizes the potential cost-saving benefits of AI adoption in the industry.

To learn more about this report – request a sample report PDF

Opportunities in the AI in food processing market include the development of intelligent automation systems and AI-powered quality control and inspection systems. These technologies can automate labor-intensive tasks, improve operational efficiency, and ensure consistent product quality. However, challenges such as high initial investment costs, vulnerability to cyberattacks, and the displacement of labor hinder widespread AI adoption in food processing. Overcoming these challenges will be crucial for realizing the full potential of AI in the industry.

AI in Food Processing Statistics

- The AI in Food Processing Market is anticipated to expand from USD 11.1 Billion in 2022 to USD 22.3 Billion by 2032, exhibiting a Compound Annual Growth Rate (CAGR) of 8.3% from 2023 to 2032. This growth trajectory underscores the increasing integration of artificial intelligence in optimizing various processes within the food industry, from safety compliance to operational efficiency.

- Simultaneously, the broader Artificial Intelligence Market is projected to attain a value of approximately USD 2,745 billion by 2032, rising from USD 177 Billion in 2023. This represents a robust CAGR of 36.8% during the forecast period from 2024 to 2033. Such exponential growth reflects the expanding applications and acceptance of AI technologies across diverse sectors.

- In 2022, the Fruits and Vegetables segment emerged as a leading category within the AI in Food Processing market, securing a predominant market share. This segment’s dominance indicates a targeted focus on enhancing the quality and efficiency of fruit and vegetable processing through AI-driven technologies.

- Furthermore, the Quality Control & Safety Compliance segment also captured a significant share of the market in 2022, highlighting the critical importance of maintaining product standards and regulatory compliance in food processing.

- Geographically, North America held the largest share of the AI in food processing market, accounting for 36.4% of the global revenue. This leadership position can be attributed to advanced technological adoption and substantial investments in AI within the region.

- Addressing the challenge of food waste, it is reported that in the United States, about 30% of all food and drink is discarded annually, equating to a financial loss of approximately USD 48.3 billion.

- In a strategic move to bolster the food processing sector, the Indian government allocated ₹3287.65 crore to the Ministry of Food Processing Industries for 2023-24, marking a 73% increase from the revised estimate of ₹1901.59 crore in 2022-23.

- The Gross Value Added (GVA) by the food processing sector in India escalated from ₹1.34 lakh crore in 2014-15 to ₹2.08 lakh crore in 2021-22, demonstrating significant economic contributions.

- Foreign Direct Investment (FDI) in the sector has been robust, with equity inflow amounting to USD 6.185 billion during the period from April 2014 to March 2023.

- Exports of processed food as a fraction of total agricultural exports surged from 13.7% in 2014-15 to 25.6% in 2022-23, illustrating the growing international demand for processed foods from India.

- Looking forward, 60% of agribusinesses intend to increase their AgTech budgets in the coming year, with purchasing priorities focused on precision agriculture tools (66%), farm management software (60%), and data consolidation (45%).

Emerging Trends

- Augmented and Virtual Reality: Augmented Reality (AR) and Virtual Reality (VR) are enhancing consumer experiences in the food industry, with applications like virtual farm tours and interactive packaging that offers additional product information.

- Cultivated Meat and Seafood: Advances in biotechnology are facilitating the development of cultivated meat and seafood, reducing environmental impact and bypassing ethical concerns associated with traditional animal farming.

- AI-Enhanced Flavor and Product Development: AI tools are being increasingly used in developing new flavors and products, such as dairy-free alternatives, by analyzing vast amounts of data to predict consumer preferences and product success.

- Electronic Noses (eNoses): These devices are becoming crucial in quality control processes within the food industry, capable of detecting odors and ensuring product consistency and safety.

- Personalized Nutrition: Leveraging AI to tailor food products to individual nutritional needs and health goals is a growing trend, highlighting the intersection of technology and personalized health care.

Top 5 Use Cases for AI in Food Processing

- Quality Control: AI systems utilize computer vision and other sensor technologies to inspect and ensure the quality and safety of food products, detecting contaminants and inconsistencies in real-time.

- Supply Chain Optimization: AI helps in forecasting demand more accurately, managing inventory, and optimizing logistics, thus reducing waste and improving efficiency.

- Consumer Engagement: AI is being used to create interactive and personalized consumer experiences, enhancing engagement through customized product recommendations and dynamic interaction platforms.

- Production Automation: From sorting raw materials to packaging finished products, AI automates numerous production line tasks, increasing speed and reducing labor costs.

- Waste Reduction: AI-driven tools assist in planning and optimizing food production cycles, significantly reducing waste through better demand forecasting and resource allocation.

Major Challenges

- Adaptation to Regulatory Standards: As AI technologies become more integrated into the food processing sector, companies face challenges in adapting to strict regulatory standards, especially concerning food safety. This includes ensuring that AI-driven processes like monitoring and compliance with safety regulations meet all legal requirements.

- High Initial Investment: The cost of implementing AI technologies in food processing is significant. High initial investments for advanced AI equipment and technologies can be a barrier for many companies, particularly small and medium-sized enterprises.

- Technical Skill Shortage: There is a notable shortage of skilled professionals who can manage and maintain AI systems in the food processing industry. This gap in technical expertise limits the capacity of companies to fully utilize AI technologies.

- Integration with Existing Systems: Integrating AI technologies with existing food processing systems poses technical challenges. Many processing plants operate with legacy systems that are not readily compatible with the latest AI solutions, requiring extensive modification or replacement.

- Data Privacy and Security Concerns: As AI systems rely heavily on data to function, issues related to data privacy and security are prominent. Companies must navigate the complexities of managing sensitive information while adhering to data protection regulations.

Market Opportunities

- Enhanced Productivity and Efficiency: AI can significantly enhance productivity and efficiency in food processing operations through automation and optimization of production lines. This includes reducing downtime and minimizing waste during the production process.

- Improved Food Safety and Compliance: AI technologies aid in improving food safety and regulatory compliance by providing advanced monitoring and detection systems that can identify potential safety issues in real time.

- Consumer Preference Insights: AI enables companies to better understand consumer preferences through data analysis, allowing for more targeted product development and marketing strategies. This can lead to the creation of customized food products that better meet consumer demands.

- Operational Cost Reduction: By automating routine tasks and optimizing resource use, AI can help reduce operational costs in food processing. This includes savings in labor, energy, and maintenance costs.

- Supply Chain Optimization: AI can optimize supply chain operations by improving forecasting accuracy, managing inventory more effectively, and enhancing logistics planning. This leads to a more efficient supply chain with reduced operational risks.

Recent Developments

- Honeywell International Inc. (May 2023): Launched Honeywell Forge for Food Safety, an AI-powered software solution for real-time food safety monitoring and risk prediction.

- ABB continues to be a significant player in the U.S. industrial automation and control systems market, focusing on the deployment of comprehensive automation and control technologies across various sectors, including food and beverage processing.

- In 2023, Key Technology introduced the COMPASS® optical sorter, which represents a significant leap in sorting technology. This new system boasts enhanced ease of use, high sorting accuracy, and is designed to be intuitive, thereby reducing operational complexity and maintenance costs. The COMPASS® sorter, like their other technologies, helps in automating quality control processes, thus boosting yield and profitability for food processors.

Conclusion

In conclusion, the AI in food processing market has witnessed significant growth and presents a promising future. The integration of artificial intelligence technologies in food processing has revolutionized the industry by improving efficiency, reducing costs, enhancing quality control, and ensuring food safety. AI algorithms and machine learning models have enabled precise monitoring and control of various processes, including sorting, grading, packaging, and quality inspection. The use of AI-powered sensors and cameras has facilitated real-time data analysis, enabling timely decision-making and proactive maintenance.

Moreover, AI has aided in optimizing production, minimizing waste, and enhancing resource utilization. With ongoing advancements in AI technology, such as deep learning and natural language processing, the potential for further innovation and automation in food processing is vast. AI-driven solutions will continue to play a crucial role in addressing the challenges faced by the food processing industry, including increasing demand, evolving consumer preferences, and stringent regulations. Ultimately, the adoption of AI in food processing is poised to reshape the industry, leading to improved productivity, sustainability, and overall customer satisfaction.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)