Table of Contents

Introduction

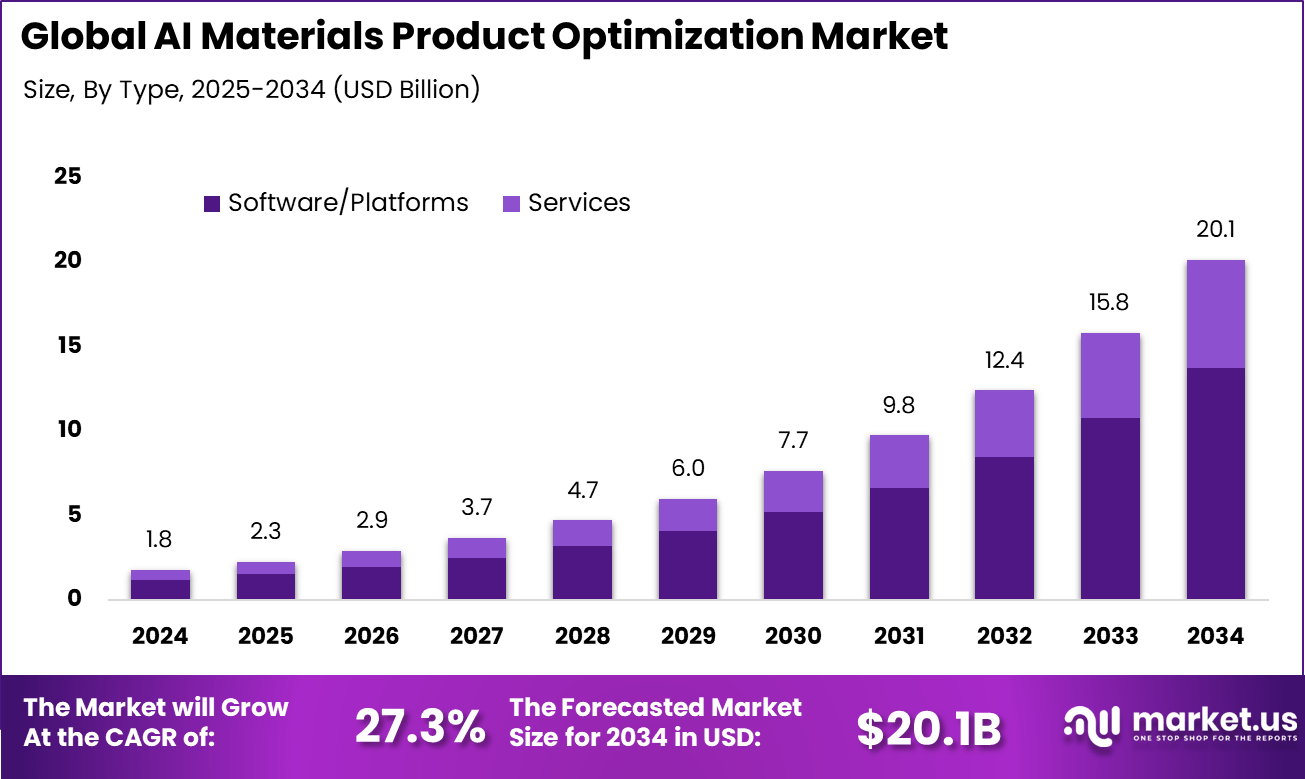

The Global AI Materials Product Optimization Market is projected to surge from USD 1.8 billion in 2024 to approximately USD 20.1 billion by 2034, reflecting a robust CAGR of 27.3%. This explosive growth is fueled by the convergence of AI technologies with materials science to reduce time-to-market, enhance product durability, and enable sustainable innovations across industries.

North America dominates the market with over 42% share in 2024, generating USD 0.75 billion in revenue, driven by rapid AI adoption, industrial automation, and government-funded innovation programs in smart manufacturing and materials research.

How Growth Is Impacting the Economy

The exponential growth of AI-driven materials optimization is reshaping global industrial productivity. It reduces R&D costs through predictive modeling, accelerates prototyping cycles, and supports sustainable manufacturing by reducing material waste and energy usage. For example, AI tools help engineers test virtual combinations of polymers, alloys, and composites before physical testing — saving millions annually. This reduces dependency on traditional, resource-intensive trial-and-error processes, thereby improving economic efficiency.

Additionally, it contributes to greener economies by enabling carbon footprint optimization in product design. The rising integration of AI in material selection, design, and production also creates new employment avenues in AI-driven engineering and materials data science, bolstering job markets and tech-based education. This growth trend is expected to elevate GDP contributions from advanced manufacturing sectors, especially in high-tech economies like the US, Germany, Japan, and South Korea.

➤ Smarter strategy starts here! Get the sample – https://market.us/report/ai-materials-product-optimization-market/free-sample/

Impact on Global Businesses

Global businesses are experiencing a paradigm shift due to AI-driven materials product optimization, marked by rising operational costs during the digital transition and shifting supply chain dependencies toward intelligent, responsive networks. Companies face initial investment burdens for AI software, infrastructure, and skilled personnel. However, these costs are mitigated by long-term gains through performance optimization and material lifecycle prediction.

Sector-specific impacts include automotive and aerospace firms benefiting from lightweight material innovations, electronics companies minimizing thermal issues through smarter substrates, and consumer goods sectors enhancing product sustainability. The shift also leads to global sourcing diversification, moving away from traditional suppliers to AI-integrated smart material labs and additive manufacturing centers.

Strategies for Businesses

- Invest in AI-driven simulation platforms to reduce prototyping costs

- Collaborate with material informatics startups for rapid innovation

- Adopt cloud-based material databases for remote design collaboration

- Implement closed-loop feedback systems to optimize real-time material use

- Upskill R&D teams in AI, data modeling, and materials science

- Focus on sustainable materials to align with ESG goals and consumer demand

Key Takeaways

- Market to grow from USD 1.8B (2024) to USD 20.1B (2034) at 27.3% CAGR

- North America leads with 42% share and USD 0.75B revenue

- AI reduces R&D cycles and enhances sustainability in material innovation

- High impact across aerospace, automotive, electronics, packaging, and pharma

- Rising demand for digital material twins, AI informatics, and real-time optimization tools

➤ Unlock growth secrets! Buy the full report – https://market.us/purchase-report/?report_id=161057

Analyst Viewpoint

Currently, the AI materials product optimization market is witnessing rapid digital transformation across traditional industries. As AI platforms mature, businesses are beginning to realize high ROI through reduced material waste and faster innovation cycles. Over the next decade, the market is anticipated to become foundational to smart manufacturing ecosystems. Government incentives, growing ESG mandates, and competitive product differentiation needs will continue to push adoption forward, particularly in sustainability-focused sectors.

Use Case and Growth Factors

| Use Case | Growth Factors |

|---|---|

| Lightweight alloy design for EVs | EV demand, emissions norms, and AI-assisted alloy selection |

| Drug delivery material optimization | Precision medicine growth and AI-based bio-compatibility modeling |

| Smart packaging in e-commerce | E-commerce growth, consumer safety, and sustainability goals |

| Aerospace thermal material simulations | Hypersonic vehicle development and AI for multi-variable thermal behavior prediction |

| Biodegradable plastics for FMCG | Green regulation compliance and AI-based polymer lifecycle modeling |

Regional Analysis

North America accounted for over 42% of the global market in 2024, owing to robust industrial R&D, early AI adoption, and strong university-industry collaboration in material sciences. The US remains a global hub for innovation with major AI-in-materials startups and government funding programs. Europe follows, driven by sustainability targets and automotive innovations. Asia-Pacific is expected to grow rapidly post-2026, fueled by electronics, packaging, and 3D printing sectors in China, Japan, and South Korea.

➤ More data, more decisions! see what’s next

- Artificial General Intelligence Market

- Wrist Wearable Devices Market

- Quantum Cloud Computing Market

- AI Career Coach Market

Business Opportunities

The AI materials product optimization market unlocks numerous business opportunities across industrial and digital domains. Startups focusing on material informatics platforms, AI model training for lab simulations, and cloud-based collaboration tools are expected to attract major investments. Companies offering solutions in green materials, recyclable composites, and thermal-efficient substrates are well-positioned for long-term contracts with global OEMs. Additionally, AI-as-a-service offerings for materials testing present a low-barrier opportunity for small and mid-sized firms to enter the market and support industrial clients transitioning to AI workflows.

Key Segmentation

The market is segmented by:

- By Material Type: Polymers, Alloys, Ceramics, Composites, Nanomaterials

- By Technology: Machine Learning, Deep Learning, Natural Language Processing, Predictive Analytics

- By Application: Product Design, R&D Simulation, Lifecycle Optimization, Smart Manufacturing

- By End-User: Automotive, Aerospace, Electronics, Healthcare, Packaging, Construction

This segmentation structure allows stakeholders to identify niche growth avenues and align product development strategies with high-impact applications.

Key Player Analysis

Key players in this market are deeply invested in expanding AI algorithms for structural prediction, multi-property optimization, and integrated cloud simulation platforms. Many are forming academic partnerships to access new materials data and validate AI models faster. Innovation roadmaps are heavily geared towards sustainability, with companies aiming to reduce environmental impact through AI-predicted low-waste manufacturing techniques. Several are also entering the subscription-based AI model licensing space to create recurring revenue streams and expand user base across geographies.

- Schrödinger

- Dassault Systèmes

- Citrine Informatics

- Kebotix

- Exabyte.io

- MAT3RA

- Phaseshift Technologies

- MaterialsZone Ltd.

- BASF SE

- AI Materia

- Intellegens

- Arzeda

- Polymerize

- Innophore

- Rescale

- Others

Recent Developments

- March 2024: A major cloud provider launched an AI materials lab simulator for real-time prototyping.

- June 2024: A leading automotive group partnered with an AI platform to optimize EV battery casings.

- September 2024: A nanotech firm announced AI-designed ceramic composites for hypersonic aircraft.

- January 2025: Launch of a government-funded AI-materials consortium in the US for circular economy applications.

- April 2025: A tech startup introduced an AI material recommender engine integrated with generative design tools.

Conclusion

AI in materials product optimization redefines how products are developed, tested, and scaled. With vast benefits in cost, time, and sustainability, businesses embracing this transformation early will gain a strong competitive edge.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)