Table of Contents

- Introduction

- Editor’s Choice

- Computer-Aided Engineering Market Overview

- History of Computer-Aided Engineering

- Technical Specifications of Computer-Aided Engineering Tools

- Design Process of Computer-Aided Engineering Statistics

- Applications of Computer-Aided Engineering in Different Industries

- Regulations for Computer-Aided Engineering Statistics

- Recent Developments

- Conclusion

- FAQs

Introduction

Computer-Aided Engineering Statistics: Computer-Aided Engineering (CAE) utilizes specialized software to simulate, analyze, and optimize engineering designs before physical prototypes are made, thus reducing costs and time in product development.

It encompasses Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), and other techniques to model stress, fluid flow, heat transfer fluids, and more.

The process involves pre-processing CAD models, running simulations, and post-processing results to inform design decisions.

CAE benefits industries such as automotive, aerospace, and electronics by improving product quality, accelerating design cycles, and enabling innovative solutions.

Despite its advantages, CAE requires skilled implementation and accurate data inputs to ensure reliable outcomes.

Editor’s Choice

- In 2023, the computer-aided engineering (CAE) market revenue stood at USD 9.5 billion.

- The deployment model of the Computer-Aided Engineering (CAE) market is characterized by a significant preference for on-premise solutions, which currently hold a 61% market share.

- The Computer-Aided Engineering (CAE) market is dominated by several key players. ANSYS, Inc. leading the industry with a 19% market share.

- The global Computer-Aided Engineering (CAE) market demonstrates diverse regional distribution, with Europe leading the market with a 33.7% share.

- The history of Computer-Aided Engineering (CAE) tools dates back to the early development of numerical control systems in the 1950s, with significant milestones shaping its evolution.

- FEA, which commands over 54% of the CAE market, simulates how products respond to real-world forces, vibrations, and other physical effects. Allowing engineers to optimize designs for strength and durability.

- In the United States, CAE practices are governed by strict industry standards and government regulations, particularly in sectors. Such as aerospace, automotive, and defense, where accuracy and safety are paramount.

Computer-Aided Engineering Market Overview

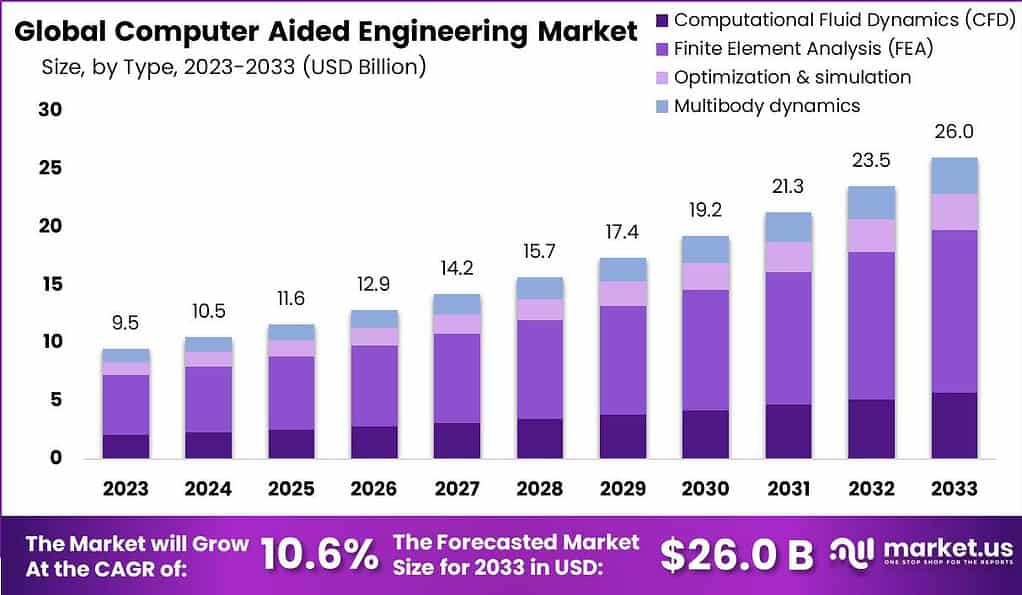

Global Computer-Aided Engineering Market Size Statistics

- The global Computer-Aided Engineering (CAE) market has exhibited significant growth at a CAGR of 10.6% over the past few years and is projected to continue this upward trend.

- In 2023, the market revenue stood at USD 9.5 billion.

- This figure is expected to rise to USD 10.5 billion in 2024 and further to USD 11.6 billion in 2025.

- The market’s growth trajectory indicates continued expansion. With revenue projections reaching USD 12.9 billion in 2026 and USD 14.2 billion in 2027.

- By 2028, the market is anticipated to generate USD 15.7 billion, escalating to USD 17.4 billion in 2029.

- The momentum is expected to sustain, with the market revenue forecasted to reach USD 19.2 billion in 2030 and USD 21.3 billion in 2031.

- By 2032, the market is projected to achieve USD 23.5 billion. Culminating in a substantial increase to USD 26.0 billion by 2033.

- This consistent growth underscores the increasing adoption and integration of CAE technologies across various industries.

(Source: market.us)

Global Computer-Aided Engineering Market Share – By Deployment Model Statistics

- The deployment model of the Computer-Aided Engineering (CAE) market is characterized by a significant preference for on-premise solutions, which currently hold a 61% market share.

- This dominance highlights the continued reliance on traditional, localized computing environments for CAE applications.

- Conversely, cloud-based solutions account for 39% of the market share. Reflecting a growing trend toward flexible, scalable, and remotely accessible CAE technologies.

- This distribution indicates a shift in the industry towards cloud adoption. Albeit at a slower pace compared to the entrenched on-premise systems.

(Source: market.us)

Competitive Landscape of the Global Computer-Aided Engineering Market Statistics

- The Computer-Aided Engineering (CAE) market is dominated by several key players. ANSYS, Inc. leading the industry with a 19% market share.

- Autodesk, Inc. follows closely with a 17% share, while Altair Engineering holds 13% of the market.

- Dassault Systèmes captures 10% of the market, and both Exa Corporation and Bentley Systems, Inc. each account for 8%.

- ESI Group has a 7% market share, and MSC Software Corporation and Mentor Graphics Corporation hold 6% and 5%, respectively.

- The remaining 8% of the market is comprised of other key players. Highlighting a competitive landscape with a mix of dominant and emerging companies in the CAE sector.

(Source: market.us)

Regional Analysis of the Global Computer-Aided Engineering Market Statistics

- The global Computer-Aided Engineering (CAE) market demonstrates diverse regional distribution, with Europe leading the market with a 33.7% share.

- The Asia-Pacific (APAC) region follows, capturing 28.4% of the market, reflecting its growing industrial and technological advancements.

- North America holds a significant 26.9% share, underscoring its robust technological infrastructure and high adoption rates of CAE solutions.

- South America accounts for 7.0% of the market, while the Middle East and Africa (MEA) region comprises 4.1%. Indicating emerging opportunities and potential for growth in these areas.

- This regional segmentation highlights the global reach and varied adoption rates of CAE technologies across different markets.

(Source: market.us)

History of Computer-Aided Engineering

- The history of Computer-Aided Engineering (CAE) tools dates back to the early development of numerical control systems in the 1950s. With significant milestones shaping its evolution.

- In 1957, Patrick Hanratty developed PRONTO, the first commercial numerical control programming system.

- Ivan Sutherland’s Sketchpad, introduced in 1963, demonstrated the potential of graphical user interfaces for engineering design.

- The 1970s saw the transition from 2D to 3D CAD systems. With innovations such as Ken Versprille’s invention of NURBS for 3D modeling.

- The 1980s brought about the commercialization of CAD software like AutoCAD and the development of solid modeling techniques.

- The introduction of Pro/ENGINEER in 1987 marked the advent of parametric modeling. This was further advanced by the creation of 3D modeling kernels like ACIS and Parasolid in the 1990s.

- The integration of high-performance computing and cloud-based solutions in the 2000s democratized access to CAE tools. Enabling their widespread application across various industries.

- These developments have continually enhanced the capabilities of CAE tools, making them indispensable in modern engineering design and analysis.

(Source: Digital Engineering, Autodesk)

Technical Specifications of Computer-Aided Engineering Tools

- Computer-aided engineering (CAE) tools offer a range of technical specifications that enhance product design and development across various industries.

- These tools include Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), and Multibody Dynamics (MBD).

- FEA, which commands over 54% of the CAE market, simulates how products respond to real-world forces, vibrations, and other physical effects. Allowing engineers to optimize designs for strength and durability.

- CFD analyzes fluid flow and heat transfer, which are essential for industries like aerospace and automotive, to predict and improve airflow and thermal management.

- MBD helps simulate the dynamic behavior of interconnected mechanical systems. Which is critical for understanding the motion and forces in mechanisms such as engines and robotic components.

- Leading CAE tools like Autodesk Fusion 360 integrate CAD, CAM, and CAE capabilities. Offering advanced simulation features to test and optimize designs digitally. Thereby reducing the need for costly physical prototypes and accelerating the product development cycle.

- This integration facilitates seamless transitions from design to manufacturing, enhancing efficiency and product quality.

(Sources: Ansys, Autodesk, PTC, Skill-Lync)

Design Process of Computer-Aided Engineering Statistics

- The design process of Computer-Aided Engineering (CAE) tools involves several key stages to ensure that products are optimized for performance, cost, and reliability.

- Initially, the process begins with computer-aided design (CAD), where the physical geometry of the product is created.

- This is followed by pre-processing, where the model is prepared for analysis by defining materials, boundary conditions, and loads.

- The core of CAE involves various types of simulations such as Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), and Multibody Dynamics (MBD).

- These simulations allow engineers to predict how the product will perform under different conditions by analyzing stress, heat transfer, fluid flow, and mechanical movements.

- Post-processing then involves reviewing the simulation results to refine and optimize the design.

- For instance, Autodesk Fusion and Siemens Simcenter provide integrated platforms that combine CAD with comprehensive CAE capabilities. Enabling virtual prototyping and reducing the need for physical tests.

- This integration helps accelerate the product development cycle. Lowering costs and enhancing product performance by allowing early identification and correction of potential issues.

(Sources: Autodesk, PTC, Siemens)

Applications of Computer-Aided Engineering in Different Industries

Manufacturing Industry

- Computer-aided engineering (CAE) is revolutionizing manufacturing by integrating advanced simulation, optimization, and validation techniques into the design and production processes.

- CAE applications, such as Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD), allow manufacturers to predict and enhance product performance under real-world conditions without extensive physical prototyping.

- For instance, in the automotive industry, companies like BMW use CAE to perform digital crash tests. Reducing both the cost and time associated with physical tests.

- Additionally, manufacturing processes like robotic welding and CNC machining benefit from CAE by optimizing operations and improving material usage.

- Tools like Autodesk Fusion and PTC’s Creo provide comprehensive CAE capabilities, supporting everything from initial design to final manufacturing, thus streamlining workflows and enhancing product quality and efficiency.

(Sources: Autodesk, PTC, Digital School)

Space Industry

- MSC Software, spearheaded by its renowned MSC Nastran code derived from NASA’s structural analysis tools for the Apollo Space Program. Has profoundly impacted society since its commercial release in 1971.

- NASA valued MSC Nastran at $10 billion in economic contribution by 2003. Underscoring its pivotal role in advancing Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD).

- Today, MSC’s tools continue to lead in space industry simulations, from the dynamics of lunar landers to novel robotic vehicles for extraterrestrial exploration.

- Recent studies, such as those by Harbin University and MIT, highlight MSC’s pivotal role in enabling innovative designs for CubeSat satellites and robotic landers capable of navigating rugged planetary terrain.

- As commercial interest in space intensifies, fueled by ventures into lunar bases, asteroid mining, and Mars colonization. MSC’s CAE solutions remain indispensable for conceptualizing and refining future space technologies and infrastructures.

(Source: International Defense, Security, and Technology)

Healthcare Industry

- Computer-aided engineering (CAE) has transformative applications in the healthcare industry, enhancing precision and efficiency in various medical processes.

- CAE is widely used in the design and manufacturing of personalized medical devices, such as prosthetics and implants, which are tailored to individual patient anatomies for better fit and function.

- Pre-operative surgical planning also benefits from CAE by allowing surgeons to simulate and plan complex procedures, thus reducing risks and improving outcomes.

- Furthermore, CAE technologies facilitate the development of sophisticated tissue engineering solutions, enabling the creation of biomimetic tissue scaffolds that support regenerative medicine efforts.

- These technologies also assist in healthcare diagnostics and management by improving the visualization and extraction of medical data, thereby aiding physicians in making more accurate treatment decisions.

- For instance, startups like Clinials use AI-driven CAE tools to optimize clinical trial recruitment. At the same time, companies like Varico utilize these technologies to create personalized treatment plans for specific conditions such as male infertility.

(Source: Springer Open, IGI Global, MDPI)

Electronics Industry

- Computer-aided engineering (CAE) is revolutionizing the electronics industry by enabling precise simulations and optimizations in product design and development.

- Applications of CAE include finite element analysis (FEA), computational fluid dynamics (CFD), and electromagnetic simulation, which are essential for the intricate design processes of printed circuit boards (PCBs) and integrated circuits (ICs).

- For instance, Altair SimSolid is a cutting-edge tool that offers rapid and accurate multi-physics simulations for complex electronic systems, significantly reducing the time and effort required for meshing and geometry simplification.

- Another example is the collaboration between Ansys and NVIDIA, which aims to advance simulation capabilities through accelerated computing and AI, facilitating the development of next-generation technologies such as 6G and autonomous vehicles.

- These advancements in CAE tools help engineers predict and address potential issues early in the design process, leading to more efficient, reliable, and cost-effective electronic products.

(Source: Ansys, Altair, Dassault Systems)

Chemical Industry

- Computer-aided engineering (CAE) is revolutionizing the chemical industry by enhancing the efficiency and accuracy of various processes.

- CAE tools such as simulation software, digital twins, and AI-driven modeling enable chemical engineers to design, test, and optimize complex chemical processes with high precision. For instance, digital twins allow real-time monitoring and simulation of chemical plants, helping in predictive maintenance and process optimization.

- Ansys, in collaboration with NVIDIA, is advancing the capabilities of simulation software using AI and accelerated computing, which significantly improves the design and testing of new chemical processes and materials.

- Additionally, startups like Tree-Tower are leveraging CAE to enable smart chemical manufacturing through virtual testing and rapid prototyping.

- These advancements not only reduce costs and enhance safety but also support sustainable practices by minimizing waste and energy consumption in chemical manufacturing processes.

(Source: Springer Open, Ansys)

Regulations for Computer-Aided Engineering Statistics

- Regulations for Computer-Aided Engineering (CAE) vary significantly across countries, reflecting different standards, compliance requirements, and industry needs.

- In the United States, CAE practices are governed by strict industry standards and government regulations. Particularly in sectors such as aerospace, automotive, and defense, where accuracy and safety are paramount.

- In Europe, regulations are often aligned with the European Union’s directives on digital engineering and simulation. Countries like Germany, the UK, and France leading in the adoption of advanced CAE technologies to maintain their competitive edge in the automotive and aerospace industries.

- Germany, in particular, mandates rigorous testing and validation processes for CAE applications in its robust automotive sector.

- In the Asia-Pacific region, countries like China and Japan have seen rapid growth in CAE adoption. Driven by government initiatives to enhance manufacturing capabilities and technological advancements.

- China‘s regulatory environment focuses on integrating CAE in industrial design applications to support its expansive manufacturing sector. While Japan emphasizes precision engineering and high-quality standards in its regulatory framework.

- These regional variations in regulations impact the development and implementation of CAE technologies, influencing market dynamics and competitive strategies globally.

(Source: U.S. Department of Commerce – National Bureau of Standards, CORDIS – European Commission, Johns Hopkins University Applied Physics Laboratory, International Journal of Engineering Education)

Recent Developments

Acquisitions and Mergers:

- Autodesk acquires Innovyze: In early 2023, Autodesk acquired Innovyze, a leader in water infrastructure software, for $1 billion. This acquisition aims to enhance Autodesk’s capabilities in engineering simulation for water infrastructure projects.

- Siemens acquires MultiMechanics: Siemens completed the acquisition of MultiMechanics, a company specializing in advanced materials modeling and simulation software, in mid-2023. This merger is expected to bolster Siemens’ Simcenter portfolio with enhanced material simulation capabilities.

New Product Launches:

- ANSYS Discovery Live: ANSYS launched Discovery Live in late 2023, an interactive simulation environment that provides real-time feedback and allows engineers to instantly see the impact of design changes on performance, aiming to streamline the design process.

- PTC Creo 9: PTC released Creo 9 in early 2024, featuring improved generative design tools, enhanced simulation capabilities, and better integration with IoT platforms, providing a comprehensive solution for product design and development.

Funding:

- Altair secures $200 million in funding: Altair Engineering, a global leader in computational science and artificial intelligence (AI), raised $200 million in a funding round in 2023 to expand its CAE software offerings and enhance its AI-driven simulation tools.

- OnScale raises $50 million: OnScale, a cloud-based CAE software provider, secured $50 million in early 2024 to further develop its platform and scale its operations globally, focusing on providing high-performance simulation solutions.

Technological Advancements:

- AI and Machine Learning Integration: The integration of AI and machine learning in CAE software is revolutionizing the industry by enabling predictive analytics, optimizing design processes, and automating complex simulations.

- Cloud-Based Simulation: Cloud-based CAE solutions are becoming more prevalent, offering scalability, flexibility, and reduced costs. These solutions allow engineers to run simulations on demand and collaborate more effectively.

Market Dynamics:

- Growth in CAE Market: The global CAE market is projected to grow at a CAGR of 9.5% from 2023 to 2028, driven by the increasing adoption of simulation tools in industries such as automotive, aerospace, and electronics.

- Adoption in SMEs: Small and medium-sized enterprises (SMEs) are increasingly adopting CAE tools due to the availability of affordable cloud-based solutions, which lower the barriers to entry and provide access to advanced simulation capabilities.

Regulatory and Strategic Developments:

- Standardization Initiatives: Industry organizations are working on standardizing CAE methodologies and data formats to ensure interoperability and consistency across different software platforms, enhancing collaboration and innovation.

- Sustainability Focus: CAE companies are focusing on sustainability by developing tools that help engineers design more energy-efficient and environmentally friendly products, aligning with global sustainability goals.

Research and Development:

- Advanced Material Modeling: R&D efforts are focusing on the development of advanced material modeling techniques to accurately simulate the behavior of new materials under various conditions, improving the reliability of simulations.

- Multiphysics Simulation: Researchers are enhancing multiphysics simulation capabilities, allowing for the simultaneous simulation of multiple physical phenomena. Such as thermal, structural, and fluid dynamics, to provide a more comprehensive analysis.

Conclusion

Computer-Aided Engineering Statistics – Computer-aided engineering (CAE) is a crucial advancement in engineering, providing tools for designing, analyzing, and optimizing products.

Techniques like Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), and Multibody Dynamics (MBD) help predict product performance, reducing the need for physical prototypes and speeding up development.

CAE enhances product quality by allowing early issue detection and optimizing designs for various conditions.

The future of CAE includes AI and cloud integration, making these tools more accessible and scalable driving innovation and efficiency across industries.

FAQs

CAE involves the use of computer software to simulate performance to improve product designs or assist in the resolution of engineering problems. It encompasses tools like Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), and Multibody Dynamics (MBD) to analyze the robustness, performance, and durability of components and assemblies.

CAE tools help reduce prototyping and testing costs, enhance product quality, and optimize designs to meet specific performance criteria. They allow engineers to simulate and analyze complex systems, reducing the time and cost associated with physical testing and enabling faster design iterations.

CAE integrates simulation into the design workflow, allowing for iterative testing and refinement. This integration helps engineers identify and address potential issues early in the design phase, improving the overall efficiency and effectiveness of the design process. Additionally, CAE tools facilitate better decision-making by providing detailed insights into the behavior of materials and components under various conditions.

CAE tools are widely used in industries such as automotive, aerospace, manufacturing, electronics, and medical devices. These industries benefit from CAE’s ability to simulate real-world conditions and optimize designs for performance, safety, and reliability.

The future of CAE includes increased integration with artificial intelligence (AI) and machine learning, which will enhance the predictive capabilities of simulation tools. Additionally, cloud-based solutions are expected to grow, providing more accessible and scalable options for businesses of all sizes. These advancements will further streamline the design process, reduce costs, and improve product innovation.