Table of Contents

Connected Manufacturing Market Size

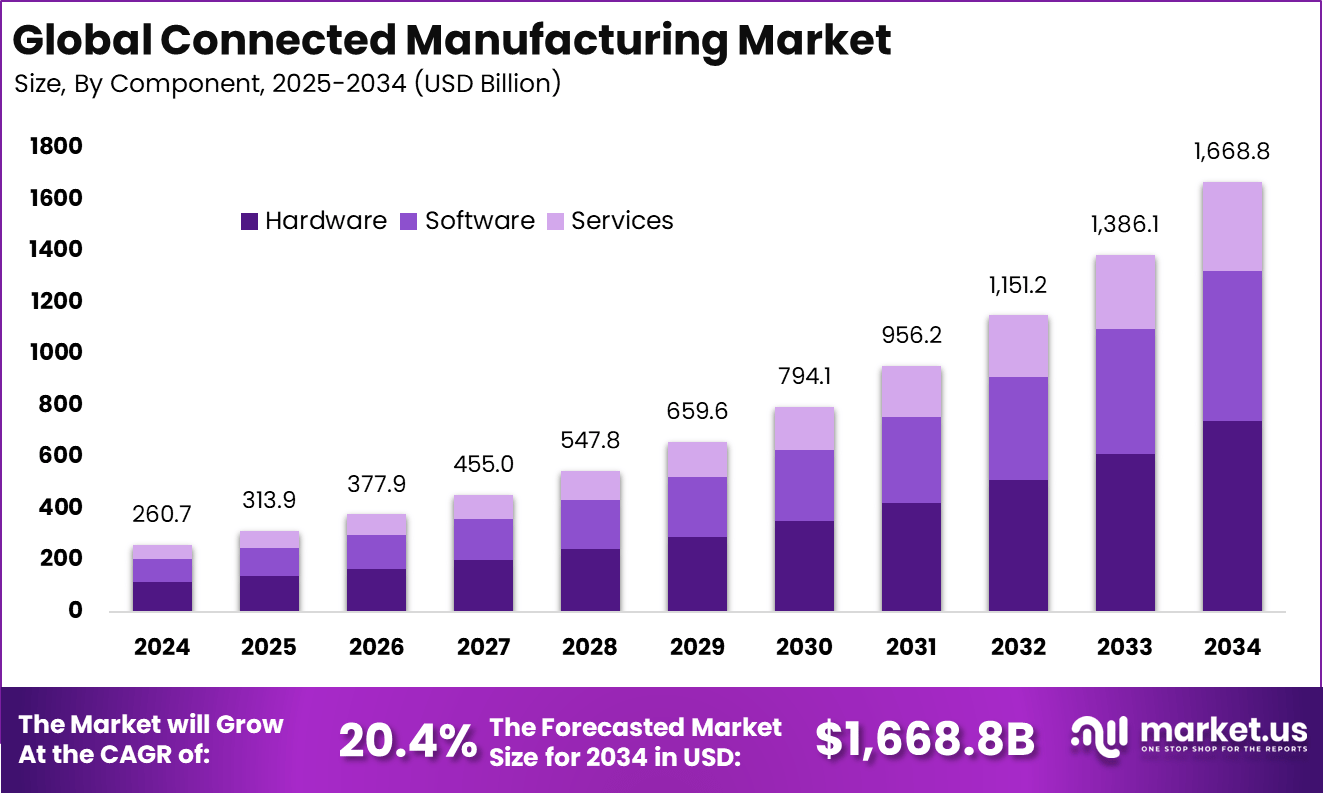

The global connected manufacturing market is projected to expand rapidly, reaching a valuation of USD 1,668.8 billion by 2034, up from USD 260.7 billion in 2024. This growth reflects a robust compound annual growth rate of 20.4% during the period from 2025 to 2034.

The rise of Industry 4.0, coupled with the integration of digital technologies such as IoT, cloud platforms, and artificial intelligence, is driving a fundamental shift in manufacturing operations. These technologies are enabling factories to enhance real-time visibility, improve process efficiency, and reduce production costs, creating a strong momentum for market adoption.

Key Takeaways

- In 2024, the Hardware segment led with 44.3% share, underscoring its pivotal role in driving connectivity across industrial systems.

- The Discrete Control Systems segment held 18.5% share, reflecting growing reliance on automation and precision-driven operations.

- By industry, the Automotive sector dominated with 25.2% share, fueled by connected vehicle production and the rise of smart factories.

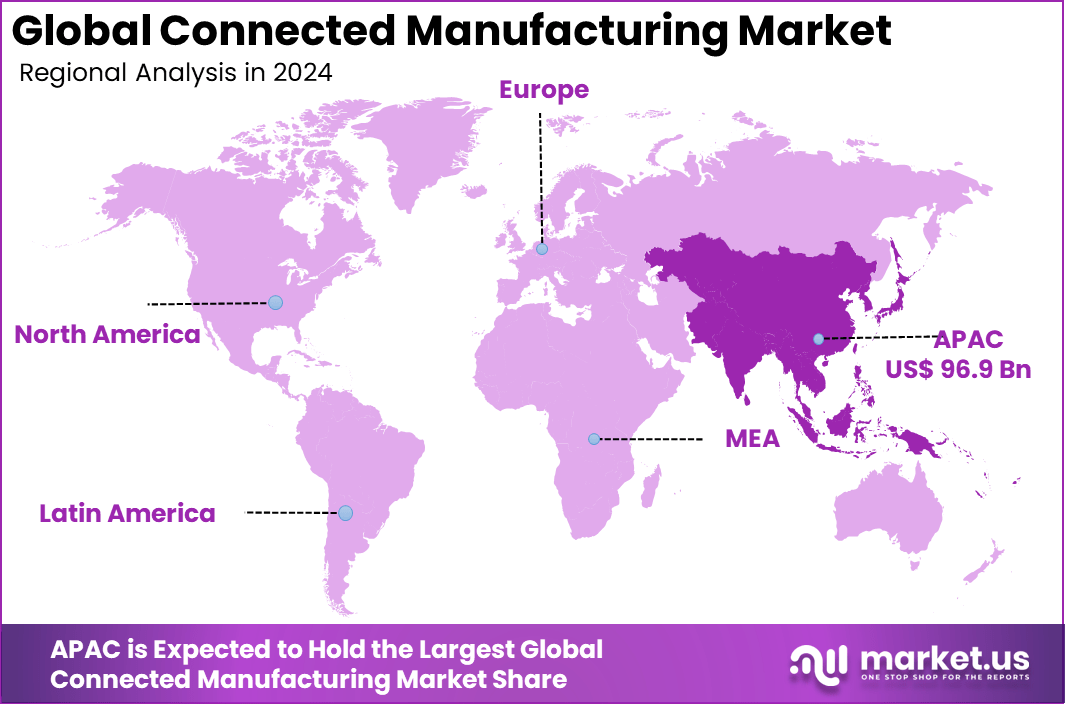

- Regionally, Asia Pacific led with 37.2% share in 2024, driven by rapid industrial digitalization and manufacturing innovation.

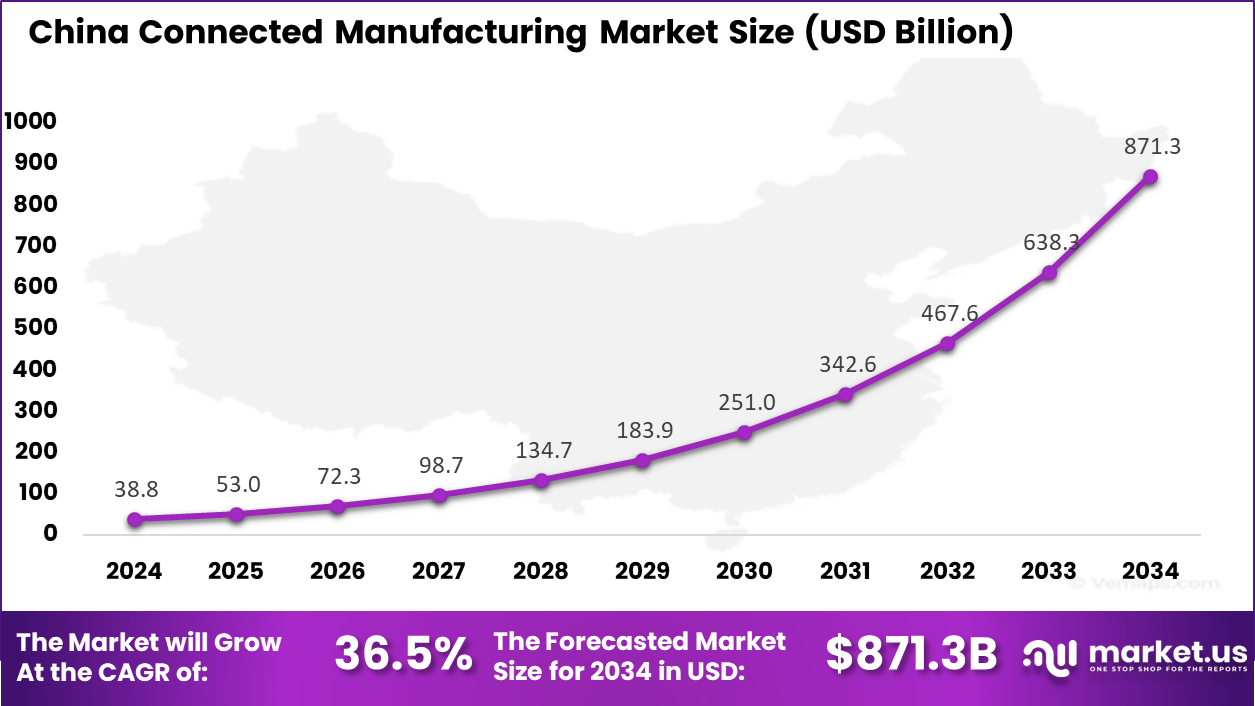

- Within the region, the China market was valued at USD 38.8 Billion in 2024, expanding at a robust CAGR of 36.5%, highlighting its leadership in connected manufacturing adoption.

Market Overview

The Connected Manufacturing Market refers to the integration of advanced digital technologies such as industrial IoT, artificial intelligence, cloud computing, and advanced analytics into manufacturing processes. It connects machines, systems, people, and supply chains through real-time data exchange, enabling smarter decision-making, predictive maintenance, and improved productivity. Connected manufacturing is a central element of Industry 4.0, transforming traditional factories into intelligent, adaptive, and highly efficient production environments.

The market is driven by the rising demand for operational efficiency, improved product quality, and reduced downtime. Manufacturers are under pressure to respond quickly to fluctuating customer needs, which is encouraging adoption of real-time monitoring and automation. Government initiatives supporting smart factory development and industrial digitalization further accelerate growth. In addition, the global push for sustainability is driving demand for connected solutions that optimize energy use and reduce waste.

One of the top driving factors in connected manufacturing is the rise of IoT integration. In 2025, studies show that about 95% of manufacturers are either using or exploring smart manufacturing technologies. IoT sensors embedded in machines, tools, and even worker devices provide real-time data that helps prevent maintenance issues, reduce downtime, and optimize workflows. Additionally, the adoption of artificial intelligence (AI) to analyze this data enables predictive maintenance and smarter decision-making, significantly improving operational efficiency.

Analysts’ Viewpoint

The demand for connected manufacturing is largely driven by the need for increased efficiency and product quality. Real-time data analytics help manufacturers reduce production waste and errors by identifying bottlenecks or quality issues early. For example, manufacturers using connected sensors report up to 20% less downtime and improvements in product consistency by monitoring critical equipment health continuously. Demand also comes from the need to reduce operational costs and support sustainability initiatives by cutting waste and energy consumption.

Investment opportunities in connected manufacturing are rising due to the increasing adoption of these technologies. Industry surveys report that over 65% of manufacturers have an industrial IoT strategy underway, with many projects exceeding expectations. Investment is accelerating in areas like smart sensors, AI software, cloud infrastructure, and 5G connectivity, which support faster data transmission and processing. New pilot projects and off-the-shelf solutions have shortened time to break even, encouraging more companies to invest.

Connected manufacturing delivers tangible business benefits including higher productivity, lower waste levels, improved product quality, and enhanced safety. Manufacturers report reductions in compliance issues by up to 40% and quality audit improvements of 25% when implementing connected systems. These benefits come from better control of production parameters, continuous quality checks, and faster response to quality or safety risks. This leads to cost savings and a stronger competitive position in the market.

China Market Size

The market for Connected Manufacturing within China is growing tremendously and is currently valued at USD 38.8 billion, the market has a projected CAGR of 36.5%.

In 2024, Asia Pacific emerged as the leading region, accounting for more than 37.2% of the global revenue and generating USD 96.9 billion. The region’s leadership can be attributed to rapid industrialization, large-scale investments in smart manufacturing infrastructure, and the strong presence of electronics and automotive production hubs. Countries such as China, Japan, and South Korea are at the forefront of adopting connected manufacturing solutions, supported by government initiatives to strengthen digital industrial ecosystems.

Driver

Enhanced Supply Chain Resilience

Connected manufacturing greatly improves supply chain resilience by creating stronger, more connected networks. After recent global disruptions, many manufacturers have focused on building supply chains that can adapt quickly to sudden changes. Connected systems allow real-time tracking of materials and products, which helps companies respond faster to delays or shortages. For instance, manufacturers can foresee potential disruptions and switch suppliers or reroute shipments proactively, avoiding costly downtime.

This resilience is vital as customer expectations have grown and supply chains have become more complex. Manufacturers that adopt connected technologies see improved reliability and trust across their supply networks. The ability to share data seamlessly not only speeds up decision-making but also reduces waste and operational risks. This driver motivates many manufacturers to invest heavily in connected solutions, improving overall efficiency and competitiveness in a volatile market environment.

Restraint

Infrastructure and Cybersecurity Limitations

Adopting connected manufacturing depends heavily on reliable digital infrastructure, which can be a significant limitation in some regions. High-speed internet and cloud connectivity are essential to enable seamless data flow between machines, systems, and stakeholders. In areas where internet connectivity is poor or unstable, implementing IoT devices and real-time monitoring becomes difficult, limiting the benefits of connected manufacturing for those companies.

Furthermore, connected manufacturing involves collecting and transmitting sensitive operational data, which increases vulnerability to cyberattacks. Many manufacturers face challenges in establishing robust cybersecurity measures to prevent data breaches, intellectual property theft, and operational disruptions. Addressing these infrastructure and security weaknesses requires upfront investment and expertise, which can restrain adoption and scale.

Opportunity

Integration of AI and IoT for Predictive Maintenance

A significant growth opportunity in connected manufacturing lies in the use of AI combined with IoT sensors to enable predictive maintenance. By continuously monitoring equipment in real time, manufacturers can predict failures before they happen and schedule maintenance proactively. This reduces unexpected downtime, lowers repair costs, and extends machine lifespans.

For instance, AI systems analyze sensor data to detect early warning signs of equipment degradation or inefficiencies. Such insights allow factories to run more smoothly, improve product quality, and optimize resource use. As more manufacturers adopt these capabilities, it creates opportunities for software and hardware providers to innovate and expand offerings in this area, driving market growth and operational gains.

Challenge

Bridging the Workforce Knowledge Gap

One pressing challenge for connected manufacturing is the growing gap in skilled workforce knowledge, especially as experienced workers retire. Manufacturing increasingly relies on digital technologies that require new skills in data analytics, IoT management, and automation controls. Many companies find it difficult to train or hire staff with the right expertise quickly enough.

This challenge affects long-term sustainability because it is not just about filling vacancies, but also about preserving institutional knowledge. When veteran employees leave without passing on their insights, companies risk losing operational intelligence critical to running complex connected systems smoothly. Effective knowledge transfer programs and training initiatives must be prioritized to maintain productivity and keep pace with technological advancements.

You May Also Read

- Creator Economy Market

- France Creator Economy Market

- Creator Economy in Virtual & Augmented Reality Market

- Creator Economy in Gaming Market

- Europe Creator Economy Market

- Content Creator Economy Market

Key Market Segments

By Component

- Hardware

- Software

- Services

By Technology

- Machine Execution Systems

- Programmable Logic Controller

- Enterprise Resource Planning

- SCADA

- Discrete Control Systems

- Human Machine Interface

- Machine Vision

- 3D Printing

- Product Lifecycle Management

- Plant Asset Management

- Others

By End-use

- Automotive

- Aerospace & Defense

- Chemicals & Materials

- Healthcare

- Industrial Equipment

- Electronics

- Food & Agriculture

- Oil & Gas

- Others

Top Key Players in the Market

- ABB Ltd.

- Siemens

- General Electric

- Rockwell Automation Inc.

- Schneider Electric

- Honeywell International Inc.

- Emerson Electric Co.

- Fanuc UK Limited

- Others

Read More – https://market.us/report/connected-manufacturing-market/

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)