Table of Contents

Introduction

A digital twin is a virtual replica or representation of a physical object, system, or process. It combines real-time data from sensors, IoT devices, and other sources to create a dynamic digital model that mirrors the behavior and characteristics of its physical counterpart. Digital twins provide valuable insights, enable predictive analysis, and facilitate optimization of operations, maintenance, and decision-making across various industries.

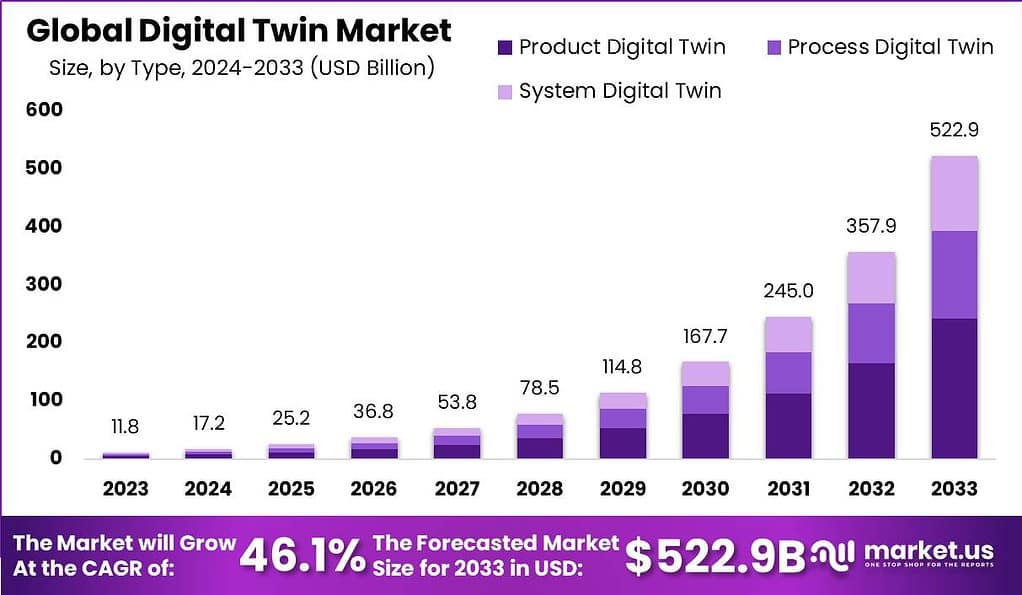

The Digital Twin Market is projected to reach a staggering USD 522.9 billion by 2033, with a robust Compound Annual Growth Rate (CAGR) of 46.1% from 2024 to 2033. The Digital Twin market is experiencing significant growth, driven by the increasing demand for advanced digital replication technologies that enable enhanced decision-making, operational efficiency, and product optimization.

The expansion of this market can be attributed to the integration of the Internet of Things (IoT), artificial intelligence (AI), and machine learning (ML) technologies, which enrich the functionality and accuracy of Digital Twins. Furthermore, the adoption of Digital Twins is being accelerated by the need for remote monitoring and predictive maintenance amidst the global shift towards digitalization.

The digital twin market presents numerous opportunities for organizations across various industries. In manufacturing, digital twins can simulate and optimize production processes, leading to improved efficiency, reduced downtime, and enhanced product quality. In healthcare, digital twins can help monitor and analyze patient data, enabling personalized treatment plans and better healthcare outcomes.

Facts and Latest Statistics

- 13% of firms engaging in Internet of Things (IoT) initiatives are already utilizing digital twins, highlighting the early adoption phase in certain sectors.

- A substantial 62% of firms are either in the midst of implementing digital twins or planning to do so, indicating a strong trajectory towards wider adoption.

- In 2023, over 60% of large manufacturers reported the use of digital twins, a significant increase from less than 30% in 2022. However, adoption among small and medium-sized firms remained lower, at approximately 25%.

- Companies that adopted digital twins in 2023 experienced a reduction in new product development cycles by an average of 15%, with some reporting reductions of up to 30%.

- The total cost savings attributed to digital twin simulations were estimated at over $700 million in 2023, primarily due to reductions in the need for physical prototypes and testing.

- The most prevalent applications of digital twins in 2023 were in product design and testing (40%), process simulation (30%), and predictive maintenance (20%).

- More than half of digital twin projects in 2023 involved IoT integration or leveraged IoT data for real-time insights and analytics.

- Cloud-based solutions dominated digital twin implementations, with over 75% of them being hosted on the cloud.

- Global spending on digital twin consulting services reached $3 billion in 2023, pointing to the lack of internal expertise as a significant barrier to adoption.

- In 2023, 25% of digital twins incorporated artificial intelligence capabilities, such as machine learning and computer vision, with predictions indicating an increase to 45% by 2024.

- Cybersecurity emerged as a critical concern, with over 30% of digital twin adopters reporting cyber attacks or data breaches on their digital shadows in 2023.

- Leading vendors in the digital twin market included Microsoft, AWS, PTC, SAP, IBM, GE, and Siemens, who collectively held a market share of over 60%.

- The market is segmented into Product Digital Twin, Process Digital Twin, and System Digital Twin, with the Product Digital Twin segment holding a revenue share of 46.3% in 2023.

- IoT and Industrial IoT (IIoT) technologies, which facilitate the creation and operation of digital twins, held a revenue share of 28.9% in 2023.

- The Automotive & Transportation sector led in digital twin adoption, securing a revenue share of 22.0% in 2023.

- North America dominated the global digital twin market with a revenue share of 37.1% in 2023, driven by its advanced technological infrastructure and proactive digital transformation strategies.

- The demand for enhanced operational efficiency and predictive maintenance significantly fuels the growth of the digital twin market.

- One of the main obstacles to widespread adoption is the high cost of implementation, which requires significant investment in technology and skilled personnel.

- Advancements in Artificial Intelligence (AI) and Machine Learning (ML) offer significant opportunities for the digital twin market by enhancing predictive analytics, intelligent automation, and decision-making capabilities.

Digital Twin Use Cases

Digital twins find applications in various domains. Here are some use cases:

- Manufacturing: In the manufacturing sector, digital twins serve as a transformative tool, enabling companies to create highly accurate virtual models of their production lines, machinery, and processes. This capability significantly enhances production efficiency by allowing manufacturers to simulate and analyze various scenarios and optimize operations without disrupting the actual production. Quality control also benefits immensely, as digital twins can predict potential defects and identify deviations in real-time, ensuring that the final product meets the desired standards. Additionally, predictive maintenance is a critical advantage; by monitoring the condition and performance of equipment virtually, manufacturers can foresee mechanical failures before they occur, reducing downtime and maintenance costs.

- Smart Cities: The application of digital twins in the context of smart cities involves creating virtual replicas of urban environments. This innovative approach aids city planners, government officials, and infrastructure managers in optimizing urban development and service delivery. By simulating different scenarios, such as traffic patterns, energy consumption, and environmental impacts, decision-makers can design more efficient, sustainable, and livable cities. Furthermore, digital twins assist in the real-time management of city infrastructure, enabling rapid response to emergencies, maintenance issues, and evolving urban challenges.

- Product Prototyping: Digital twins revolutionize the product development process by enabling companies to test and refine their designs virtually before committing to costly physical prototypes. This approach allows for a more iterative and flexible design process, where products can be optimized for performance, usability, and manufacturability in a virtual environment. It reduces the time and expense associated with traditional prototyping, speeding up the time-to-market and increasing the likelihood of a product’s success. By identifying potential issues and opportunities for improvement early in the design phase, companies can achieve higher quality and innovation in their products.

- Real-Time Process Modeling: Real-time process modeling with digital twins involves the continuous monitoring and analysis of processes through their virtual counterparts. This capability enables organizations to make informed, data-driven decisions promptly. For example, in an industrial setting, a digital twin of a chemical production process can help operators adjust parameters in real time to optimize yield or reduce energy consumption based on live data feeds. This dynamic approach to process management enhances operational efficiency, reduces costs, and improves overall performance by leveraging the power of real-time data and analytics.

Emerging Trends

The digital twin market is undergoing a period of significant transformation, driven by advancements in technology and shifting industry needs. Below, key emerging trends are outlined, reflecting the evolving landscape of this market:

- Integration with Internet of Things (IoT) and Industrial IoT (IIoT): The convergence of digital twins with IoT technologies is enhancing real-time data collection and analysis. This integration allows for more dynamic and accurate representations of physical assets, facilitating improved decision-making and operational efficiency.

- Expansion into Healthcare and Life Sciences: Digital twins are increasingly being applied in healthcare and life sciences for patient monitoring, personalized medicine, and the simulation of biological systems. This trend is driven by the potential to improve patient outcomes and accelerate medical research.

- Increased Emphasis on Sustainability: With growing awareness of environmental issues, there is a push towards using digital twins to model and optimize energy consumption, reduce emissions, and enhance resource efficiency in various industries, including manufacturing and construction.

- Advancements in AI and Machine Learning: The integration of AI and machine learning technologies with digital twins is enabling more sophisticated analysis and predictive capabilities. These technologies can anticipate maintenance needs, optimize operations, and simulate future scenarios with greater accuracy.

- Adoption in Smart Cities and Urban Planning: Digital twins are being utilized in the development of smart cities, aiding in urban planning, infrastructure management, and the optimization of public services. This application aims to improve the quality of life for residents and reduce environmental impacts.

Top 5 Market Leaders

- General Electric Co.: General Electric stands at the forefront of the digital twin revolution, primarily within the industrial sector. Its Predix platform offers advanced analytics, which, when coupled with its extensive industrial expertise, enables predictive maintenance and operational efficiency. GE’s commitment to innovation in this space underscores its role as a catalyst for the broader adoption of digital twin technologies across various industries.

- Microsoft Corporation: Microsoft has leveraged its cloud infrastructure, Azure, to create a robust environment for digital twins, emphasizing scalability and security. Through Azure Digital Twins, Microsoft enables integration across a wide range of IoT solutions, offering comprehensive models that enhance operational insights and efficiency. This strategic focus positions Microsoft as a key enabler of digital transformation for businesses globally.

- Hitachi, Ltd.: Hitachi integrates its rich industrial heritage with cutting-edge digital technologies to offer advanced digital twin solutions. Its Lumada platform exemplifies this integration, providing actionable insights to optimize operations and drive innovation. Hitachi’s approach to digital twins, focusing on societal impact and industrial efficiency, showcases its commitment to leveraging technology for sustainable development.

- Dassault Systèmes SE: Dassault Systèmes excels in creating detailed simulations and virtual environments with its 3DEXPERIENCE platform, which extends across various sectors including manufacturing, healthcare, and urban planning. This capability to simulate complex systems in virtual environments positions Dassault Systèmes as a leader in not only designing products but also in envisioning and testing entire ecosystems before they are physically built.

- Autodesk, Inc.: Autodesk’s contribution to the digital twin market is underscored by its comprehensive software suite that supports the design, simulation, and construction of buildings and infrastructure. Through its BIM (Building Information Modeling) and generative design technologies, Autodesk facilitates the creation of digital twins that are crucial for the architecture, engineering, and construction sectors, driving efficiency and sustainability in project development.

Recent Developments

- General Electric Co. (GE) – July 2023: GE expanded its Predix IIoT platform, introducing advanced data visualization and analytics tailored for digital twin management in industrial environments. This move enhances GE’s capabilities in creating and managing sophisticated digital replicas of physical assets.

- Microsoft Corporation – October 2023: Microsoft launched Azure Digital Twins, a scalable managed service on its cloud platform. This development allows users to effortlessly construct and oversee digital twins, reinforcing Microsoft’s dominance in the cloud-based digital twin sphere.

- Hitachi, Ltd. – March 2023: Hitachi unveiled the Lumada Digital Twin Solution, a versatile platform that merges data from physical assets, operational systems, and AI to facilitate the creation and management of digital twins across diverse sectors. This innovation highlights Hitachi’s commitment to integrating technology with practical industrial applications

Conclusion

In conclusion, the digital twin market is driven by the increasing adoption of IoT devices, advancements in cloud computing and analytics, and the demand for remote monitoring and control. The market offers opportunities for organizations to optimize operations, improve efficiency, and drive innovation. As digital twin technology continues to evolve, it is expected to play a significant role in transforming industries and enabling more data-driven decision-making and predictive capabilities.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)