Table of Contents

Introduction

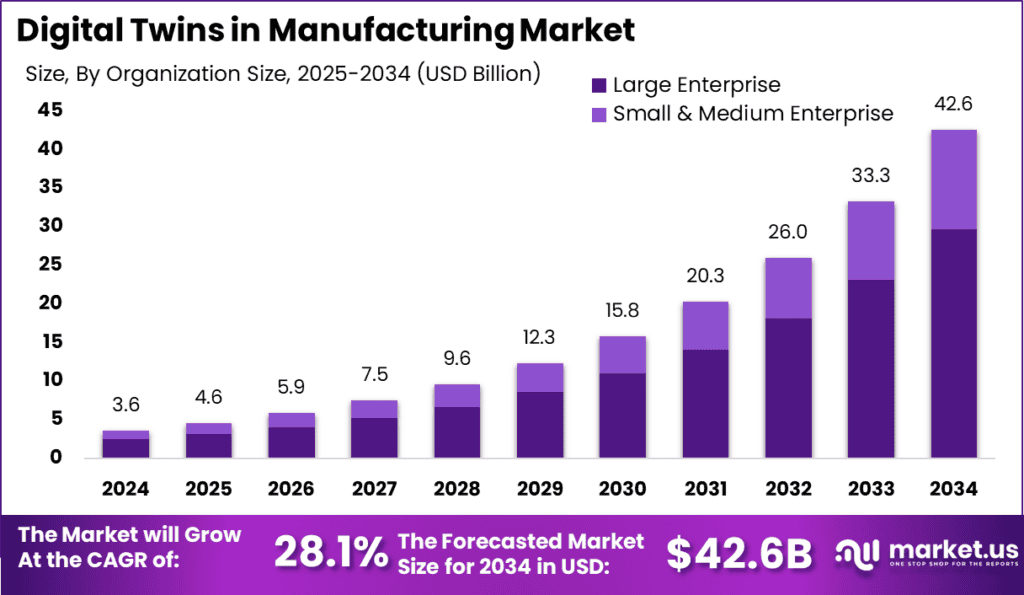

The global digital twins in manufacturing market is experiencing rapid growth, with an expected market size of USD 42.6 billion by 2034, up from USD 3.6 billion in 2024. This market is projected to grow at a remarkable compound annual growth rate (CAGR) of 28.1% from 2025 to 2034.

Digital twin technology allows manufacturers to create virtual replicas of physical assets, enhancing operational efficiency, reducing downtime, and facilitating predictive maintenance. This technology is being widely adopted in industries such as automotive, aerospace, and electronics, as manufacturers look to improve product quality, minimize costs, and optimize production processes.

How Growth is Impacting the Economy

The increasing adoption of digital twin technology is positively impacting the global economy by driving innovation, increasing productivity, and optimizing resource utilization in manufacturing. By enabling real-time monitoring and simulation of physical assets, digital twins allow companies to identify inefficiencies and predict failures before they occur, reducing operational costs.

The growing demand for automated solutions in industries like automotive, electronics, and aerospace is fueling the market’s expansion. As more manufacturers adopt digital twin technology, economies benefit from higher efficiency, reduced waste, and improved competitiveness, especially in the global manufacturing sector. In addition, the adoption of digital twins contributes to sustainability goals, as they help in reducing energy consumption, waste, and emissions, which aligns with global environmental targets.

➤ To Elevate Your Business – Request Sample Here @ https://market.us/report/digital-twins-in-manufacturing-market/free-sample/

Impact on Global Businesses

Rising costs, supply chain disruptions, and sector-specific challenges are increasingly shaping the impact of digital twins on global businesses. The shift toward digital twin technologies helps companies mitigate the effects of rising raw material costs and fluctuating demand by enabling better resource planning and real-time adjustments. For businesses in sectors like automotive and electronics, digital twins streamline the production process, reducing downtime and minimizing the impact of supply chain disruptions.

Manufacturers can predict maintenance needs, adjust production schedules, and ensure more reliable supply chains. The ability to virtually model entire systems and processes allows businesses to stay competitive in a dynamic market environment. Moreover, sector-specific impacts include the ability for aerospace and automotive companies to refine design processes, leading to faster go-to-market times and increased product reliability.

Strategies for Businesses

To capitalize on the growth of digital twins in manufacturing, businesses need to invest in technology adoption, workforce training, and strategic partnerships. Companies should integrate digital twin solutions with their existing enterprise systems, such as enterprise resource planning (ERP) and supply chain management platforms, to create a seamless flow of data. Additionally, businesses must focus on enhancing their IT infrastructure to support real-time data processing and analytics. Collaboration with technology providers and the hiring of skilled professionals with expertise in IoT, AI, and data analytics will be crucial to fully harness the potential of digital twin technologies.

Key Takeaways

- The global digital twins in manufacturing market is expected to grow from USD 3.6 billion in 2024 to USD 42.6 billion by 2034.

- North America leads the market, holding a 33.7% share in 2024.

- The market is projected to grow at a CAGR of 28.1% from 2025 to 2034.

- Adoption of digital twin technology is key to improving efficiency, reducing operational costs, and enabling predictive maintenance.

- Businesses must invest in IT infrastructure and employee training to stay competitive in the digital age.

➤ Quick Purchase Full Report Here @ https://market.us/purchase-report/?report_id=151216

Analyst Viewpoint

Currently, the digital twins in the manufacturing market are positioned for significant growth, driven by the demand for automation and efficiency in manufacturing processes. The future looks promising as more industries adopt this technology to enhance their production capabilities.

The integration of AI and IoT with digital twin solutions will further expand the potential for innovation and operational improvements across various sectors. As more companies realize the long-term cost benefits of digital twins, the market is expected to see continued expansion and transformation, creating new opportunities for players across the value chain.

Regional Analysis

In 2024, North America is leading the digital twins in manufacturing market with a 33.7% market share, accounting for USD 1.2 billion in revenue. The region’s dominance is driven by strong investments in automation and advanced manufacturing technologies, particularly in the automotive and aerospace sectors. Europe follows closely, supported by growing adoption in industries such as energy and consumer electronics.

The Asia Pacific region is also expected to experience rapid growth due to increasing industrialization and the rising demand for manufacturing optimization in countries like China and India. Other regions, including Latin America and the Middle East, are expected to witness gradual growth as digital transformation initiatives are implemented.

Business Opportunities

The digital twins market presents several business opportunities, particularly in the areas of system integration, IoT solutions, and data analytics. Technology providers and system integrators can tap into the increasing demand for real-time data analytics and predictive modeling solutions in the manufacturing sector. The growing emphasis on sustainability in manufacturing also presents opportunities for businesses to offer energy-efficient digital twin solutions.

Additionally, there is potential for growth in the development of industry-specific digital twin solutions tailored to sectors such as automotive, aerospace, and energy. As the technology continues to evolve, companies providing innovative software and platforms will be able to capitalize on new market needs.

➤ Discover More Trending Research

Key Segmentation

The digital twins in manufacturing market is segmented by technology, including AI, IoT, and blockchain solutions. Another key segmentation is by industry, with automotive, aerospace, electronics, and energy sectors being the key adopters. In terms of deployment, solutions are primarily divided into cloud-based and on-premise models.

The cloud-based deployment segment is expected to grow the fastest, owing to its flexibility and scalability. The market is also segmented by application, with key use cases including predictive maintenance, process optimization, and product design simulation. Geographically, North America and Europe are the leading regions, while Asia Pacific is expected to see the fastest growth.

Key Player Analysis

In the digital twins in manufacturing market, key players focus on providing comprehensive solutions that integrate IoT, AI, and cloud computing. These players are enhancing their offerings by including predictive analytics, simulation capabilities, and real-time data processing features.

To stay ahead in this competitive market, companies are also focusing on building strategic partnerships with other technology providers and expanding their R&D efforts to develop industry-specific solutions. Additionally, firms are investing in building strong customer relationships and providing tailored solutions that meet the unique needs of various manufacturing sectors.

- Siemens Industry Software Inc.

- GE Vernova Inc.

- Microsoft Corporation Company Profile

- NVIDIA Corporation

- IBM Corporation

- PTC Inc.

- Dassault Systèmes SE

- Bentley Systems, Incorporated

- Oracle Corporation

- Bosch Business Innovations GmbH

- Rockwell Automation, Inc.

- Hexagon AB

- Ansys, Inc.

- SAP SE Company Profile

- Matterport, Inc.

- Others

Recent Developments

- In 2024, a leading technology provider launched an enhanced digital twin platform with real-time data analytics capabilities, targeting the automotive sector.

- A prominent player in the aerospace industry introduced a digital twin-based predictive maintenance solution, reducing downtime and operational costs.

- A new partnership between a software company and a manufacturing firm aimed to integrate AI-powered digital twins for optimized production lines.

- A global electronics manufacturer unveiled a digital twin initiative to streamline its supply chain and improve product quality.

- In 2024, a major industrial IoT company expanded its digital twin portfolio to include customized solutions for the energy sector.

Conclusion

The digital twins in the manufacturing market are experiencing rapid growth and offer significant opportunities for businesses to enhance operational efficiency and reduce costs. The increasing adoption of this technology across various sectors positions it as a key driver of future industrial transformation.