Table of Contents

Introduction

According to Gas sensor statistics, Gas sensors detect and measure specific gases in diverse environments using principles like chemical reactions, physical adsorption, and optical absorption.

Types include electrochemical, catalytic, infrared, semiconductor, and photoionization detectors, each tailored to specific gas types and applications.

Electrochemical sensors offer sensitivity and low power usage for portability, while catalytic sensors excel in industrial settings detecting combustible gases.

Infrared sensors identify gases like carbon dioxide, semiconductor sensors are versatile and cost-effective, and photoionization detectors specialize in volatile organic compound detection.

Widely used in industrial safety, environmental monitoring, automotive emissions control, healthcare, and indoor air quality assessment, gas sensors significantly contribute to safety, efficiency, and environmental preservation.

Key selection factors include target gases, detection range, environmental conditions, response time, and cost-effectiveness.

Editor’s Choice

- The global gas sensors market revenue reached USD 2,748 million in 2023.

- By 2032, wireless gas sensors are forecasted to contribute USD 2,492 million to the market, surpassing wired sensors’ revenue of USD 2,810 million.

- Carbon dioxide dominates the gas landscape with a commanding market share of 32.5%, followed closely by carbon monoxide at 23.0%.

- A 0% LEL indicates an absence of combustible gas, while a 100% LEL signifies that the gas concentration is at its lower explosive limit.

- The MQ2 gas sensor, a prominent member of the MQ sensor series, is widely employed due to its Metal Oxide Semiconductor (MOS) type and its reliance on Chemiresistors, where gas detection hinges on changes in material resistance upon gas exposure.

- The MQ-7 sensor is designed to detect carbon monoxide (CO) levels in the air, with a detection range of 10 to 500 parts per million (ppm).

- Proper CO2 monitoring indoors not only enhances cognitive functions but also reduces airborne diseases. One popular solution for IAQ and the HVAC industry is the CozIR®-LP2 CO2 Sensor, known for its low power consumption and extended lifespan.

Global Gas Sensors Market Overview

Global Gas Sensors Market Size

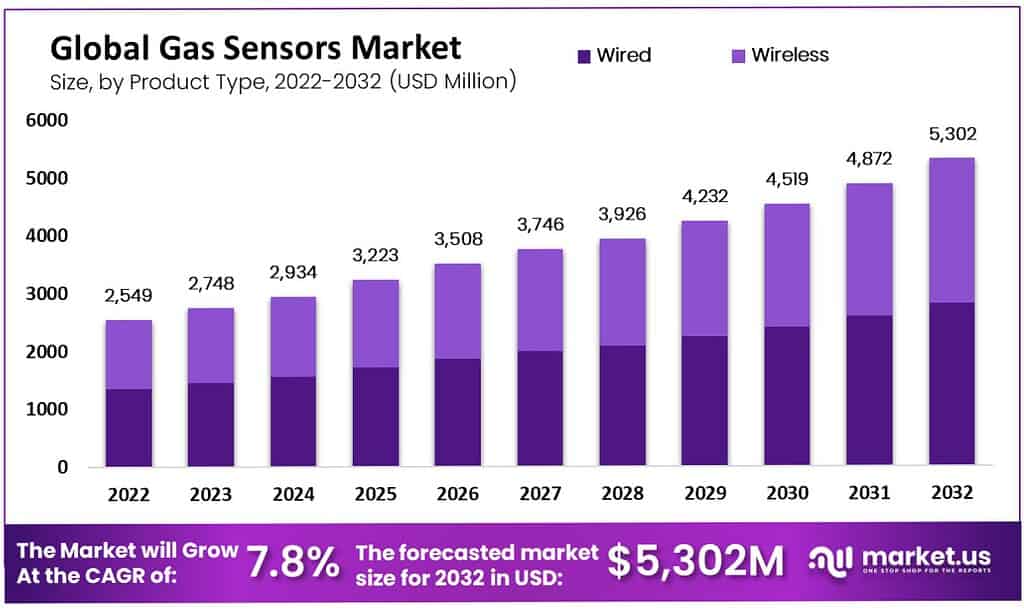

- The global gas sensors market has shown consistent growth in revenue over the years at a CAGR of 7.80%, reflecting increasing demand and adoption across various industries.

- In 2022, the market revenue stood at USD 2,549 million, which grew to USD 2,748 million in 2023 and further to USD 2,934 million in 2024.

- The upward trajectory continues with projected revenues of USD 3,223 million in 2025, USD 3,508 million in 2026, and USD 3,746 million in 2027.

- By 2031, the market revenue is forecasted to reach USD 4,872 million, further escalating to USD 5,302 million in 2032.

Gas Sensors Market Size – By Product Type

- The global gas sensors market has demonstrated steady growth over the past decade, with revenues reaching USD 2,549 million in 2022 and projected to rise consistently, reaching USD 5,302 million by 2032.

- In 2022, wired gas sensors accounted for USD 1,351 million in revenue, while wireless sensors generated USD 1,198 million.

- However, the wireless segment is expected to experience faster growth, outpacing wired sensors in revenue by 2030.

- This trend reflects advancements in wireless technology, enabling greater flexibility, scalability, and cost-effectiveness in sensor deployments.

- By 2032, wireless gas sensors are forecasted to contribute USD 2,492 million to the market, surpassing wired sensors’ revenue of USD 2,810 million.

Global Gas Sensors Market Size – By Gas Type

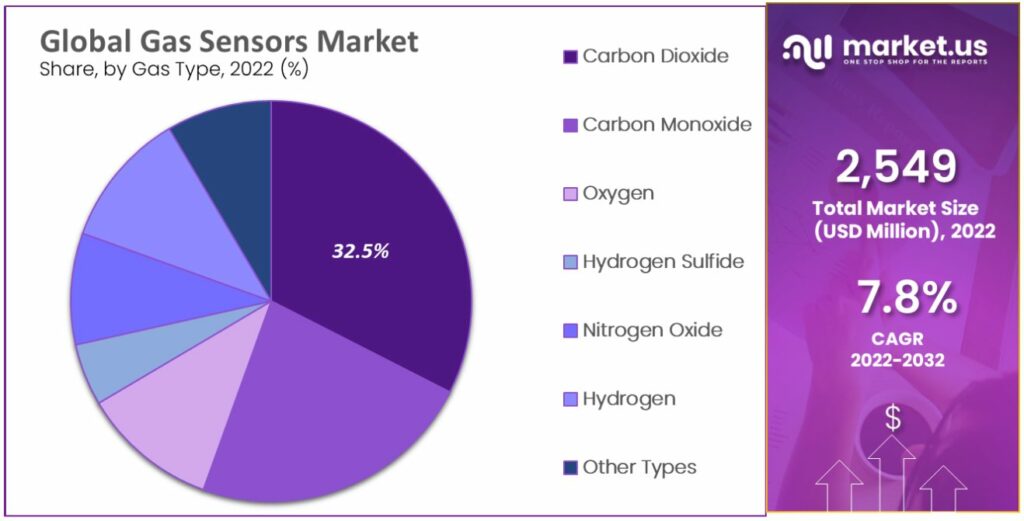

- In the global gas sensors market, various gas types exhibit distinct market shares, reflecting their significance in industrial, commercial, and residential applications.

- Carbon dioxide dominates the landscape with a commanding market share of 32.5%, followed closely by carbon monoxide at 23.0%. These gases are pivotal in environmental monitoring, combustion processes, and safety applications.

- Oxygen and hydrogen hold notable shares of 11.0% each, which is crucial for applications ranging from medical devices to industrial processes.

- Hydrogen sulfide and nitrogen oxide contribute 5.0% and 9.0%, respectively, reflecting their importance in detecting potentially hazardous environments.

- Additionally, hydrogen, with an 11.0% share, plays a significant role in hydrogen fuel cells and hydrogen-powered vehicles.

- The remaining 8.5% is attributed to other gas types, highlighting the diverse array of gases monitored by gas sensors, including volatile organic compounds and flammable gases.

Technical Specifications of Gas Sensors

Combustible Gas

- The Lower Explosive Limit (LEL) or Lower Flammable Limit (LFL) of a combustible gas represents the minimum concentration of the gas needed to sustain a flame when mixed with air or oxygen and ignited. In gas detection systems, gas concentration is typically measured as a percentage (%) of LEL.

- A 0% LEL indicates an absence of combustible gas, while a 100% LEL signifies that the gas concentration is at its lower explosive limit.

- The relationship between percent LEL and percent by volume varies depending on the gas. Trace concentrations are expressed in parts per million (ppm) or parts per billion (ppb), with 1% exposure equivalent to 10,000 ppm or 10,000,000 ppb.

- Combustible gas-air mixtures can catch fire across a broad range of concentrations, typically from around 0.5% to 15% by volume in the air for common hydrocarbons. This concentration is consistently referred to as 100% LEL or LFL for the gas.

Electrical Outputs

- Analog voltage outputs usually have a direct, linear correlation with the measured value. Frequency or modulated frequency outputs include different types like frequency modulation (FM), amplitude modulation (AM), sine waves, and pulse trains.

- Analog current levels, such as 4 – 20 mA transmitters, are well-suited for transmitting signals across long distances.

Well-known Gas Sensors and their Applications

MQ-2 Flammable Gas and Smoke Sensor Module

- The MQ2 gas sensor, a prominent member of the MQ sensor series, is widely employed due to its Metal Oxide Semiconductor (MOS) type and its reliance on Chemiresistors, where gas detection hinges on changes in material resistance upon gas exposure.

- It features a module version with a Digital Pin for standalone operation without a microcontroller, simplifying single gas detection tasks. For gas measurement in ppm, the analog pin is utilized, which operates at 5V TTL and is compatible with most microcontrollers.

- Operating on 5V DC, the MQ2 sensor consumes approximately 800mW power and detects concentrations of alcohol, propane, LPG, smoke, hydrogen, methane, and carbon monoxide ranging from 200 ppm to 10000 ppm.

MQ-3 Alcohol Detector Gas Sensor Module

- The MQ-3 module utilizes SnO2 as its sensitive substance to detect alcohol, benzene, CH4, hexane, LPG, and CO, displaying lower conductivity in clean air.

- In the presence of alcohol gas, the sensor’s conductivity increases relative to the gas concentration, showcasing a notable sensitivity to alcohol while remaining resistant to fuel, smoke, and mist.

- Operating at 5V DC and consuming approximately 800mW, the MQ-3 sensor can identify alcohol concentrations ranging from 25 ppm to 500 ppm.

MQ-4 Methane Gas Sensor Module

- The MQ-4 module is specially made to detect Methane and CNG Gas.

- It runs on 5V DC power and uses about 750mW of electricity.

- This sensor can pick up methane and natural gas levels ranging from 300 to 10,000 parts per million (ppm).

- It’s housed in a casing crafted from plastic and stainless steel netting, and inside, you’ll find components like a measuring electrode, a micro AL2O3 ceramic tube, a Tin Dioxide (SnO2) sensitive layer, and a heater.

Applications of Gas Sensors

Safety Industries

- Gas detection and monitoring play a vital role in safeguarding individuals working in hazardous environments where dangerous gases may be present.

- The core of any gas detector lies a specialized gas sensor designed to continuously monitor and measure gas concentrations, alerting to elevated levels for enhanced safety.

- For instance, the S8 5% CO2 Sensor serves as a crucial safety measure in various settings like agriculture facilities, industrial plants, restaurants, and dry ice storage, functioning as an alarm system to ensure prompt response to CO2 levels beyond the norm.

Indoor Air Quality/HVAC Industries

- Gas sensor technologies are widely utilized in monitoring indoor air quality (IAQ), covering various enclosed spaces like homes, offices, classrooms, gyms, and assisted living facilities.

- These sensors not only serve as early warning indicators for rising CO2 levels but also contribute to energy efficiency and HVAC system longevity.

- Proper CO2 monitoring indoors not only enhances cognitive functions but also reduces airborne diseases. One popular solution for IAQ and the HVAC industry is the CozIR®-LP2 CO2 Sensor, known for its low power consumption and extended lifespan.

Aerospace Industries

- Gas sensor technologies play a crucial role in the aerospace industry, particularly in measuring oxygen and carbon dioxide concentrations.

- These sensors are essential for monitoring in-flight conditions and maintaining air quality to ensure crew productivity and passenger comfort.

- An intriguing study conducted as part of the National University Capstone Project focused on oxygen safety masks, utilizing CM-42951 0-25% UV Flux Oxygen Smart Sensor.

- This sensor enabled aerospace researchers to accurately measure oxygen concentrations passing through an F-35 Lightning II Pilot Mask.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)