Table of Contents

Market Overview

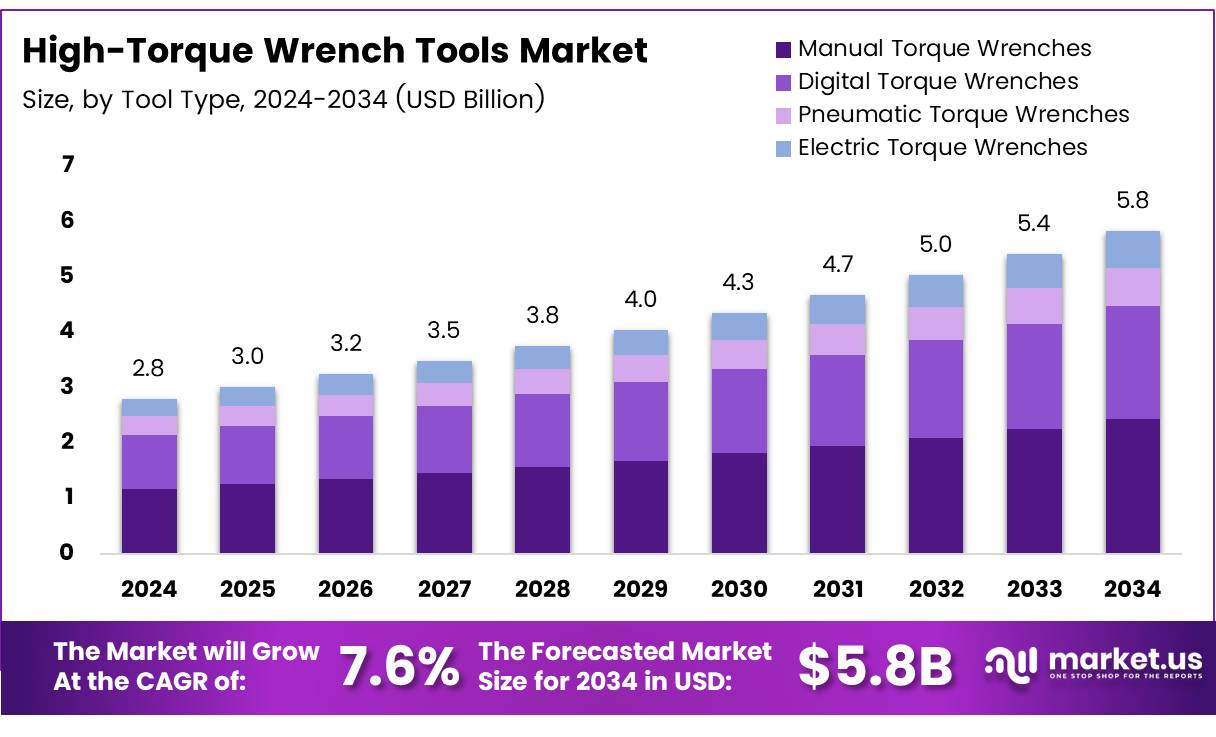

The Global High-Torque Wrench Tools Market size is expected to be worth around USD 5.8 Billion by 2034, from USD 2.8 Billion in 2024, growing at a CAGR of 7.6% during the forecast period.

The High-Torque Wrench Tools Market is growing steadily. Demand is rising in oil & gas, construction, and heavy machinery. About 50% of equipment failures are due to bolt problems. This is driving the need for accurate torque tools. Manufacturers are launching durable and precise products. The ESCO Pneumatic Torque Wrench offers +/- 5% accuracy. It delivers torque from 78 ft/lbs. to 5,990 ft/lbs. Hardened alloy steel ensures long life and performance.

Government investment is boosting market growth. Projects in infrastructure and renewable energy need high-torque tools. These tools improve efficiency and safety. Regulations are enforcing strict quality standards.

Companies are adopting advanced torque solutions. This reduces downtime and prevents accidents. Global demand is shifting to reliable fastening systems. High-torque wrenches support industrial productivity.

Key Takeaways

- The global high-torque wrench tools market will reach USD 5.8 billion by 2034, growing at a 7.6% CAGR from 2025 to 2034.

- Manual torque wrenches dominate due to reliability, cost-effectiveness, and precision.

- The automotive sector leads applications, driving strong market demand.

- The professional segment holds the largest share, fueled by precision and heavy-duty needs.

- North America leads with 36.6% market share, worth about USD 1.0 billion, driven by automotive, aerospace, and oil & gas industries.

Market Drivers

- Rising Industrial Applications: Demand grows in heavy industries for reliable, high-performance fastening under extreme conditions.

- Infrastructure Development: Large-scale global projects require precise high-torque assembly tools.

- Workplace Safety & Efficiency: Enhances precision, reduces fatigue, and minimizes accident risks.

- Technological Advancements: New ergonomic, digital, and lightweight designs improve tool performance.

Opportunities

- Renewable Energy Projects: Wind turbine installation and maintenance require precise bolt fastening at extreme heights and in varying weather conditions, making high-torque wrenches critical.

- Automation Integration: Smart torque tools that connect with digital monitoring systems are gaining popularity in advanced manufacturing plants.

- Emerging Markets: Rapid industrialization in developing regions is creating a strong customer base for advanced fastening solutions.

Segmentation Insights

Tool Type Analysis

In 2024, manual torque wrenches dominated due to their reliability, low cost, and precision, serving automotive, construction, and manufacturing needs. Digital, pneumatic, and electric models have niche roles, but manual tools remain the most used for their simplicity and proven performance.

Application Analysis

The automotive industry led the market in 2024, using high-torque wrenches for precise assembly and safety. Aerospace, construction, manufacturing, oil & gas, and shipbuilding also contributed significantly to demand.

End-User Analysis

Professionals drove the market in 2024, relying on these tools for industrial precision and durability. The DIY segment is growing but remains smaller compared to professional use.

Regional Insights

North America dominated in 2024 with 36.6% share (USD 1.0 billion), driven by strong industrial demand and tech advances.

Europe grew steadily on the back of manufacturing and automotive sectors but at a slower pace.

Asia Pacific is set for the fastest growth, boosted by industrialization and infrastructure projects in China, India, and Japan.

MEA and Latin America are emerging markets, supported by oil & gas, construction, and automotive expansion.

Recent Developments

- In July 2025, Atlas Copco Group received the prestigious Red Dot Design Award 2025 for its innovative industrial assembly tool, the MTRwrench. This recognition highlights the company’s commitment to combining ergonomic design with high-performance engineering in industrial solutions.

- In January 2025, Sonic Group completed the acquisition of Sonic Tools USA, its exclusive North American distribution partner. This strategic move strengthens Sonic Group’s direct presence in the U.S. market and enhances its customer service and distribution efficiency.

Conclusion

The global high-torque wrench tools market is set for robust growth, reaching USD 5.8 billion by 2034 at a 7.6% CAGR. Rising industrial applications, infrastructure expansion, and government investments are fueling demand, while North America currently leads the market. Manual torque wrenches remain dominant, with strong uptake in automotive and professional sectors. Emerging markets, renewable energy projects, and automation integration present major growth opportunities, supported by ongoing innovations and strategic industry moves.