Table of Contents

Introduction

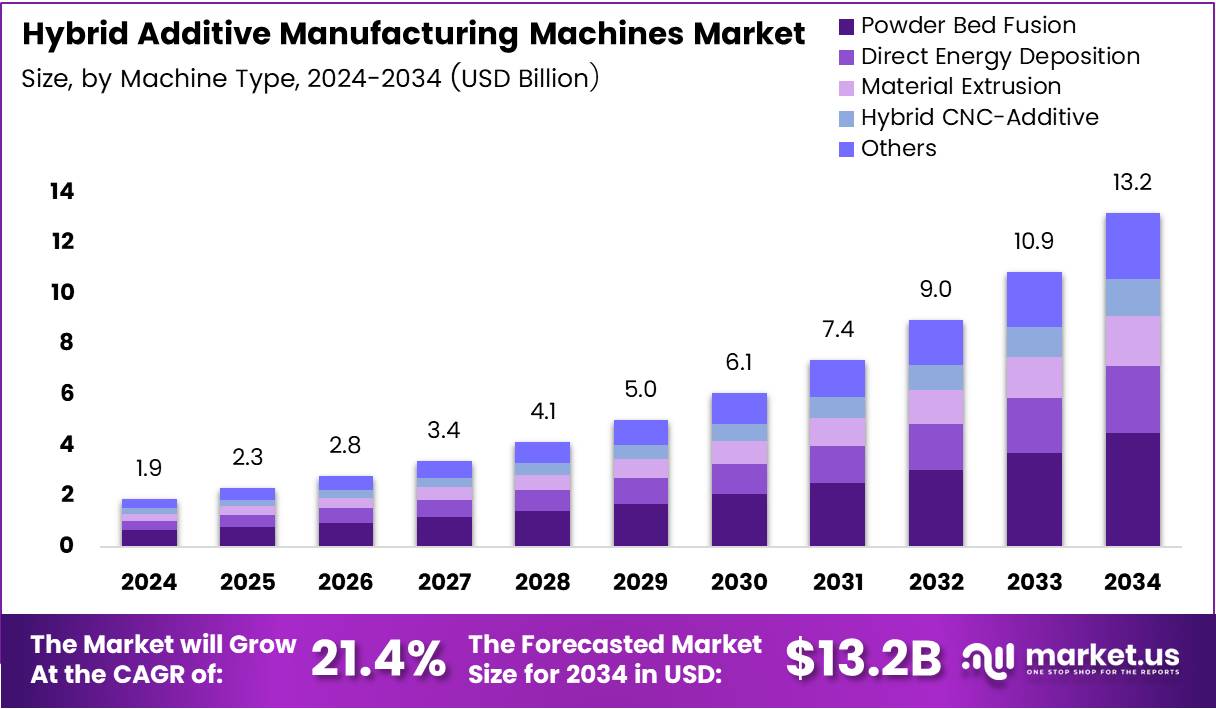

The Global Hybrid Additive Manufacturing Machines Market is rapidly evolving, blending additive and subtractive processes to revolutionize production efficiency. Valued at USD 1.9 Billion in 2024, it is projected to reach USD 13.2 Billion by 2034, expanding at an impressive CAGR of 21.4% during 2025–2034.

This growth is propelled by advancements in multi-material processing and automation across industrial sectors. Hybrid manufacturing enables complex geometries, improved material utilization, and faster production, driving adoption in aerospace, automotive, and medical applications. Additionally, governments worldwide are promoting digital transformation to boost smart manufacturing capabilities.

As companies seek cost-efficient and sustainable production methods, hybrid additive manufacturing emerges as a key enabler of innovation. It supports Industry 4.0 initiatives, enabling flexibility, precision, and waste reduction, which collectively strengthen competitiveness in global manufacturing ecosystems.

Key Takeaways

- The Global Hybrid Additive Manufacturing Machines Market is projected to reach USD 13.2 Billion by 2034, growing from USD 1.9 Billion in 2024 at a CAGR of 21.4% (2025–2034).

- In 2024, Powder Bed Fusion led the By Machine Type segment with a 34.8% share, driven by high-resolution printing and complex geometry capabilities.

- Titanium Alloys dominated the By Material Type segment in 2024, holding a 27.6% share due to their mechanical strength and biocompatibility.

- The Aerospace & Defense sector led the By End-Use segment in 2024 with a 32.3% share, owing to its demand for precision and material efficiency.

- North America was the leading region with a 48.3% share, valued at USD 0.9 Billion, supported by strong adoption in aerospace, automotive, and defense industries.

Market Segmentation Overview

By Machine Type: Powder Bed Fusion dominated the market in 2024 with a 34.8% share due to its scalability and superior surface finish. Direct Energy Deposition is gaining traction for component repair, while Material Extrusion and Hybrid CNC-Additive systems support prototyping and high-precision part manufacturing.

By Material Type: Titanium Alloys led with 27.6% market share in 2024, valued for strength and corrosion resistance. Aluminum Alloys offer lightweight solutions, Stainless Steel ensures durability, and Nickel Alloys provide heat resistance. Ceramics and composites are emerging materials for specialized hybrid applications.

By End-Use: Aerospace & Defense dominated with 32.3% share, driven by the need for lightweight and complex components. The medical sector is expanding rapidly with customized implants, while automotive, energy, and electronics industries leverage hybrid systems for efficiency and design flexibility.

Drivers

Rising Adoption in Aerospace and Defense: The growing need for intricate and lightweight components in aerospace and defense drives hybrid additive manufacturing. These machines enable superior precision and material efficiency, producing mission-critical parts with high structural integrity and reduced waste.

Advancements in Multi-Axis CNC Integration: The integration of multi-axis CNC systems enhances hybrid manufacturing capabilities, offering design freedom and improved surface finishes. This synergy between additive and subtractive techniques enables high-performance production suitable for complex, high-value components.

Use Cases

Rapid Tooling and Mold Fabrication: Hybrid machines are transforming tooling processes by shortening lead times and improving flexibility. Manufacturers can produce molds and tools directly from digital designs, reducing setup time and enabling faster transitions from design to production.

Customized Medical Implants: The medical sector leverages hybrid systems to produce patient-specific implants with superior biocompatibility. These machines combine internal structural complexity with precise external finishing, ensuring improved performance and reduced surgical adjustment time.

Major Challenges

High Initial Investment: The significant upfront cost of hybrid additive systems poses a barrier to entry, particularly for small and medium-sized enterprises. Maintenance and training expenses further limit widespread adoption despite long-term efficiency benefits.

Lack of Standardization and Skilled Workforce: Variations in machine architecture and software ecosystems hinder interoperability. Additionally, a shortage of skilled operators capable of managing both additive and subtractive processes restricts effective implementation and optimal utilization.

Business Opportunities

Expansion in Medical and Orthopedic Manufacturing: The demand for customized implants and orthopedic devices creates a major growth avenue. Hybrid systems enable precision fabrication of complex geometries, supporting innovations in healthcare manufacturing and patient care advancements.

Integration with Industry 4.0 and Smart Factories: Connecting hybrid machines to IoT platforms and AI-driven analytics allows predictive maintenance and process optimization. This digital integration enhances productivity, reduces downtime, and supports sustainable production environments.

Regional Analysis

North America: Dominating with a 48.3% market share valued at USD 0.9 Billion, North America leads in hybrid additive manufacturing adoption. Strong R&D investments, advanced manufacturing infrastructure, and government initiatives supporting industrial digitization drive regional growth.

Asia Pacific: The region is witnessing rapid industrialization and technological advancement, particularly in China, Japan, and South Korea. Investments in hybrid systems are boosting productivity and precision, enabling Asia Pacific to emerge as the fastest-growing market in this domain.

Recent Developments

- In March 2025, Sodick announced the acquisition of a majority stake in Prima Additive to strengthen its position in metal additive manufacturing and hybrid AM systems.

- In August 2025, Schoeller-Bleckmann Oilfield Equipment (SBO) acquired 3T Additive Manufacturing, expanding its industrial-grade 3D printing and metal AM services across aerospace and energy sectors.

- In 2024, ODeCon launched the adAM-BASE, a cost-effective hybrid additive manufacturing machine integrating laser-based DED and CNC machining, priced below approximately €300,000 to support SMEs and research institutions.

Conclusion

The Global Hybrid Additive Manufacturing Machines Market is set for substantial expansion, powered by advancements in automation, materials, and smart manufacturing. With strong adoption in aerospace, defense, and healthcare, the market’s integration into Industry 4.0 ecosystems promises enhanced productivity, sustainability, and design flexibility. As technological innovation accelerates, hybrid manufacturing will play a pivotal role in shaping the next generation of industrial production worldwide.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)