Table of Contents

Introduction

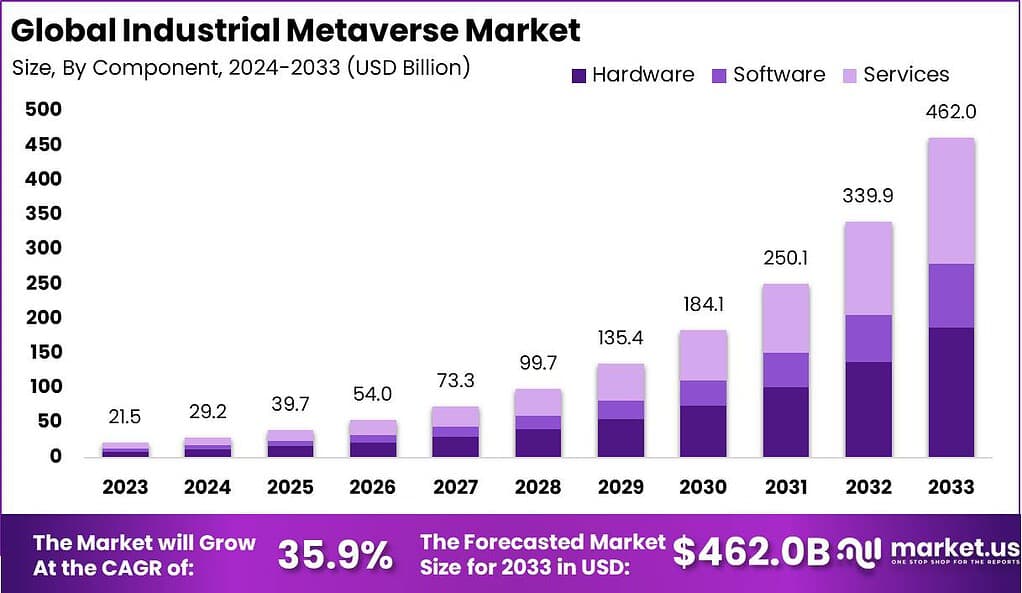

According to Market.us, The Global Industrial Metaverse Market is projected to experience significant growth, with its size expected to reach approximately USD 462.0 billion by 2033, up from USD 21.5 billion in 2023. This substantial expansion represents a compound annual growth rate (CAGR) of 35.9% during the forecast period from 2024 to 2033.

The rapid growth of this market can be attributed to the increasing adoption of advanced technologies such as augmented reality (AR), virtual reality (VR), and artificial intelligence (AI) in industrial applications. These technologies are transforming traditional manufacturing processes, enhancing efficiency, and enabling real-time data analysis. Additionally, the integration of the Industrial Metaverse is anticipated to revolutionize supply chain management, improve worker training programs through immersive simulations, and facilitate remote collaboration and troubleshooting. As industries increasingly recognize the value of these innovations, significant investments and technological advancements are expected to drive the market’s robust growth trajectory.

The Industrial Metaverse refers to a digital environment where industry-specific virtual simulations, augmented reality (AR), and artificial intelligence (AI) converge to create interactive, immersive platforms for various sectors such as manufacturing, energy, logistics, and healthcare. This concept extends the idea of the metaverse-traditionally associated with social and gaming applications – to more technical, practical uses in industrial settings. Within this virtual space, companies can perform tasks such as designing and testing new products, training employees with virtual replicas of real-world machinery, and optimizing operations through simulations that predict outcomes based on different variables.

However, embracing the Industrial Metaverse also presents challenges. High setup costs, the need for significant technological infrastructure, and concerns about data security and privacy are significant hurdles. Additionally, there is a steep learning curve for employees to adapt to these advanced technologies.

Despite these challenges, the opportunities are vast. The Industrial Metaverse allows for innovation in product design and operations management, potentially reducing time and cost for R&D and enabling more precise decision-making. It also opens up new markets for technology providers and gives traditional industries a chance to reinvent their business models. As companies continue to navigate its complexities, the Industrial Metaverse stands as a promising frontier for industrial transformation.

Key Takeaways

- The Global Industrial Metaverse Market is poised for significant expansion, with projections indicating growth from USD 21.5 Billion in 2023 to approximately USD 462.0 Billion by 2033. This represents an impressive Compound Annual Growth Rate (CAGR) of 35.9% from 2024 to 2033.

- In 2023, the Hardware segment maintained a dominant position in the Industrial Metaverse sector, securing over 40.5% of the total market share. This highlights the essential role of hardware components in facilitating industrial applications of metaverse technologies.

- The Augmented Reality (AR) segment also demonstrated substantial market penetration, accounting for more than 33.1% of the market. This significant share emphasizes the growing utilization of AR technologies to enhance interactive and immersive experiences in industrial environments.

- In terms of industry-specific adoption, the Manufacturing sector emerged as a prominent user of metaverse solutions, capturing over 24.3% of the market in 2023. This trend indicates an accelerating shift towards digital transformation in manufacturing processes via advanced virtual and augmented reality technologies.

- Regionally, North America exhibited market leadership with a commanding share of over 35%, translating to revenues of USD 7.5 billion. This dominance is a reflection of the region’s strong technological infrastructure and swift adoption of innovative technologies across various industries.

Industrial Metaverse Statistics

- The Global Metaverse Market is poised for exponential growth, with projections indicating a surge from USD 94.1 billion in 2023 to an impressive USD 2,346.2 billion by 2032. This represents a robust Compound Annual Growth Rate (CAGR) of 44.4% during the forecast period from 2024 to 2033.

- In a 2023 Deloitte study, an impressive 92% of manufacturing executives reported that their companies are either experimenting with or have already implemented metaverse-related use cases. On average, these companies are managing over six different use cases. The impact of these initiatives is significant, with executives anticipating improvements of 12% to 14% in critical performance metrics such as sales, throughput, and quality over the next few years.

- Furthermore, the Global Digital Twin Market is poised for explosive growth. Analysts from market.us project that the market size will skyrocket from USD 11.8 Billion in 2023 to approximately USD 522.9 Billion by 2033, reflecting a CAGR of 46.1% during the forecast period from 2024 to 2033. This growth underscores the increasing adoption and integration of digital twins in various industries, enhancing operational efficiency and decision-making processes.

- In the realm of augmented reality (AR), while industrial and manufacturing applications currently dominate the market share, healthcare applications are on a rapid ascent. With uses ranging from training to surgical simulations and vein visualization, the healthcare segment is expected to grow at a CAGR of 44% through 2030.

- Lastly, the 2023 Global Product and Service Innovation Survey revealed that 25% of manufacturing respondents are already utilizing industrial metaverse environments for collaborative efforts in engineering, manufacturing, and service delivery. This indicates a growing recognition of the metaverse’s potential to revolutionize traditional industrial practices by enhancing collaboration and innovation across global teams.

- The Global Industrial Metaverse Market is set to experience rapid growth, starting from USD 21.5 billion in 2023 and expected to reach USD 462.0 billion by 2033, reflecting a CAGR of 35.9%. Initial growth will be driven by the adoption of augmented reality (AR), virtual reality (VR), and artificial intelligence (AI) in industrial applications.

- By 2025, the market is projected to reach USD 39.7 billion, continuing to expand as investments in metaverse-related hardware, software, and services increase.

- Entering the 2030s, the market will see exponential growth, reaching USD 184.1 billion by 2030 and USD 339.9 billion by 2032. By 2033, the market is anticipated to achieve a substantial USD 462.0 billion, highlighting the transformative impact of metaverse technologies on industrial processes, driving efficiency, collaboration, and innovation.

Emerging Trends

- Integration of Digital and Physical Realms: The Industrial Metaverse is advancing towards seamlessly blending digital content with physical objects, enhancing operational efficiency across various sectors like manufacturing, automotive, and healthcare.

- Adoption of Spatial Computing: There’s a growing trend towards using spatial computing to merge real-time information with the physical environment, which can significantly influence industries by providing immersive experiences that are contextually aware of the user’s environment.

- Advancement of Digital Twins: The evolution from individual digital twins to interconnected platforms is shaping the future of the Industrial Metaverse. This allows for more comprehensive simulations and real-time analytics across different platforms and devices.

- Expanded Use of XR Technologies: Extended Reality (XR) technologies are increasingly integrated into industrial operations, improving training, product testing, and operational procedures by creating more interactive and precise simulations.

- Collaborative and Inclusive Development: There’s a significant push towards developing the Industrial Metaverse in a way that is equitable, accessible, and inclusive, promoting global collaboration and shared understanding of its potential and applications.

Top Use Cases

- Enhanced Training and Simulation: Utilizing AR and VR, industries can enhance employee training, allowing them to interact with complex machinery or operational processes in a safe, controlled virtual environment. This reduces onboarding times and improves learning curves

- Remote Monitoring and Assistance: Through digital twins and XR tools, companies can monitor operations remotely, allowing experts to provide real-time assistance and guidance without being physically present, thus improving maintenance and operational efficiency.

- Product Design and Development: Companies are leveraging AR and VR for product design and development, allowing them to test and modify products under simulated conditions. This not only speeds up time-to-market but also enhances product quality and sustainability.

- Operational Efficiency: Smart factory technologies and the Industrial Metaverse are enabling companies to gather and analyze data from their operations to make informed decisions that enhance efficiency, reduce costs, and increase safety.

- Customer Engagement: AR technologies are being used by retailers to enhance customer experiences by allowing them to visualize products in a more interactive way. This has been shown to significantly increase sales and customer engagement.

Key Factors Influencing Market Growth

The growth of the Industrial Metaverse market is driven by a confluence of technological advancements and strategic industry needs. Here are some key factors influencing its growth:

- Technological Integration: The integration of Virtual Reality (VR), Augmented Reality (AR), and Artificial Intelligence (AI) is fundamental. These technologies provide immersive experiences and realistic training simulations, crucial for industries like manufacturing where precision and efficiency are paramount.

- Digital Twins and IoT: The use of digital twins, which are virtual replicas of physical systems, is becoming increasingly prevalent. These allow for better simulation, prediction, and optimization of processes. The integration of IoT enhances real-time monitoring and control, further driving efficiency.

- Data Analytics: Advanced data visualization and analytics are critical as they transform complex data into actionable insights within virtual environments, improving decision-making and operational efficiency.

- Improved Collaboration and Training: The Industrial Metaverse enables remote collaboration and advanced training capabilities across geographical boundaries, which is especially valuable in a globalized business environment.

- Accessible AR Technologies: Advancements in mobile technology have lowered barriers to AR adoption, allowing more businesses to utilize sophisticated AR features without significant upfront investment. This has led to broader implementation across various sectors.

- Market Readiness and Investment: The market is responding positively, with substantial investments flowing into the development and deployment of metaverse technologies. This is evidenced by rapid market growth projections and the involvement of leading tech companies.

Major Challenges

- Lack of Standards: The absence of universally accepted standards leads to interoperability issues among different metaverse platforms, as major tech companies vie for dominance in setting these standards.

- Technological Limitations: Current technology may not support the extensive computing power required for massive user engagement or the advanced graphical details expected in metaverse environments.

- Limited Adoption Among Certain Demographics: Some age groups are hesitant to adopt metaverse technologies, presenting a challenge for companies targeting a broader demographic.

- Cost and Accessibility: The high cost of necessary digital hardware and the lack of inclusivity for users with visual impairments or other disabilities limit the accessibility of metaverse experiences.

- Social Impact: The potential negative effects on face-to-face human interaction, particularly among younger generations, pose a social challenge to the widespread adoption of metaverse technologies.

Top Opportunities

- Immersive Training and Simulations: The use of VR and AR for training and simulations enhances operational efficiency and offers realistic scenarios without the risks associated with physical training.

- Digital Twins for Predictive Maintenance: Leveraging digital twins can significantly enhance predictive maintenance capabilities, allowing for timely interventions and reduced downtime.

- Enhanced Data Visualization and Analytics: Advanced analytics and data visualization capabilities within the metaverse enable better decision-making by transforming complex data into understandable and actionable insights.

- Remote Collaboration: The metaverse facilitates seamless collaboration across geographically dispersed teams, which is invaluable for global operations.

- Supply Chain Optimization: Real-time visibility and control over the supply chain through metaverse platforms can lead to significant improvements in efficiency and cost reduction.

Recent Developments

Microsoft Corporation

- July 2023: Microsoft announced plans to scale its industrial metaverse through the AI Cloud Partner Program. This initiative will support the development of immersive technologies aimed at enhancing enterprise productivity and sustainability by integrating AI, cloud computing, and mixed reality solutions.

- November 2023: At Ignite 2023, Microsoft unveiled a strategic initiative to integrate generative AI into Dynamics 365 Guides for HoloLens. This aims to optimize factory operations and improve efficiency by providing real-time, hands-free interaction for workers using AI and mixed reality.

Siemens AG

- June 2024: Siemens announced a significant investment of approximately €1 billion in developing enterprise-grade metaverse solutions. This investment aims to establish Siemens as a leader in industrial metaverse technology, focusing on enhancing global technology activities and innovation within the industrial sector.

NVIDIA Corporation

- March 2023: NVIDIA collaborated with Microsoft to enhance the industrial metaverse and AI solutions. This partnership provides Microsoft’s enterprise users access to NVIDIA’s AI-driven technologies, aiming to boost productivity and operational efficiency through advanced simulation and visualization tools.

Conclusion

The industrial metaverse presents a transformative landscape that intertwines the physical and digital realms, offering extensive opportunities for innovation and efficiency in industrial processes. However, its adoption is not without challenges, mainly revolving around technological limitations, standardization, and socio-economic barriers.

Overcoming these hurdles is crucial for businesses aiming to capitalize on the significant advantages that the industrial metaverse promises, such as enhanced training, predictive maintenance, and operational efficiencies. As the technology matures and becomes more accessible, it is expected that more industries will integrate metaverse solutions into their operations, driving further growth and innovation in this dynamic market.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)