Table of Contents

Introduction

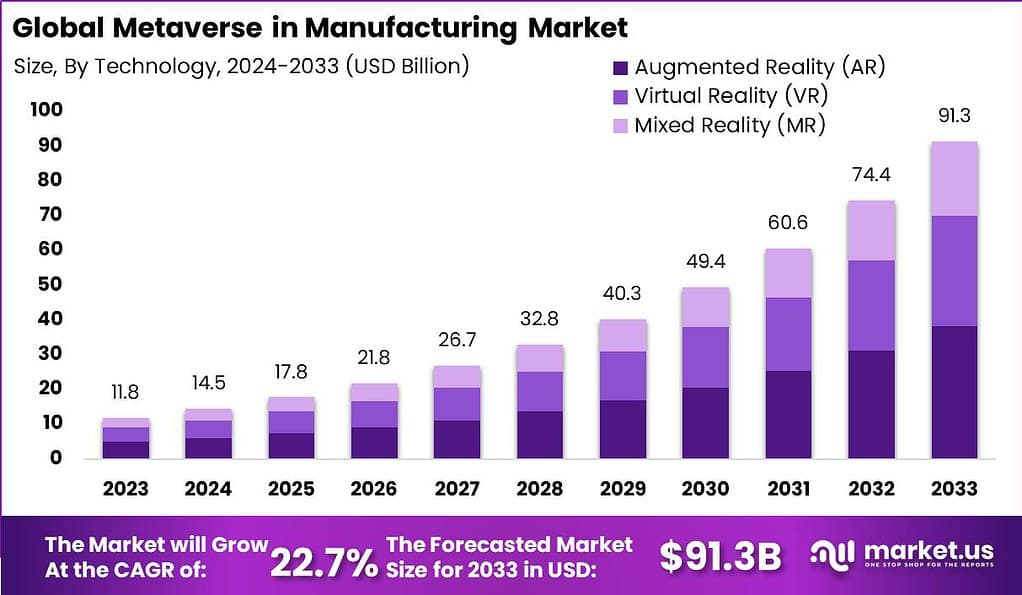

The Metaverse in Manufacturing Market is expected to grow significantly over the next decade, driven by advancements in technology and increased adoption of virtual and augmented reality (VR/AR) in industrial settings. The market size is projected to increase from USD 11.8 billion in 2023 to USD 91.3 billion by 2033, with a compound annual growth rate (CAGR) of 22.7% from 2024 to 2033.

Several factors contribute to this growth. Key drivers include the integration of digital twins and IoT technologies, which enhance operational efficiency through real-time monitoring and predictive maintenance. There is also a growing demand for immersive VR/AR training and remote assistance, which helps reduce onboarding times and improve safety in manufacturing environments. Notable developments include Microsoft’s Azure Mixed Reality services and Meta Platforms’ advancements in Oculus VR headsets, which are increasingly being used for industrial applications.

Recent developments in the Metaverse in Manufacturing sector have been marked by significant mergers, acquisitions, and funding activities. In January 2024, Synopsys announced the acquisition of Ansys for $35 billion, aiming to enhance its capabilities in virtual simulation and digital twin technologies. Another notable deal was Hewlett Packard Enterprise’s acquisition of Juniper Networks for $14 billion, bolstering its networking and cloud infrastructure to support metaverse applications. Furthermore, Meta Platforms (formerly Facebook) continued its expansion in the metaverse space with a $2.5 million investment to support European academic research on metaverse technologies.

In April 2023, Epic Games secured $1 billion in funding, with $200 million from Sony Group Corporation, to advance its metaverse initiatives, including in the manufacturing sector. Additionally, Siemens acquired Bright Machines for $1.2 billion, focusing on integrating advanced robotics and automation solutions within the industrial metaverse. These strategic moves reflect the growing importance and investment in the metaverse to revolutionize manufacturing processes, enhance operational efficiencies, and drive innovation across the industry.

Key Takeaways

- The Metaverse in Manufacturing Market is projected to achieve a substantial size, estimated at USD 91.3 billion by 2033, with a remarkable compound annual growth rate (CAGR) of 22.7% during the forecast period.

- The market was valued at USD 11.8 billion in 2023, indicating significant growth potential in the coming years.

- Augmented Reality (AR) dominated the market in 2023, capturing over 41.8% of the market share, showcasing its pivotal role in enhancing manufacturing processes.

- Product Design and Development emerged as the leading application segment in 2023, holding a market share of more than 34.3%. This highlights the significance of the metaverse in innovating product design practices.

- North America led the market in 2023, holding a commanding share of over 35.2%, driven by its robust technological infrastructure and early adoption of advanced manufacturing technologies.

- Microsoft Corporation, Unity Technologies, and NVIDIA Corporation emerged as key players shaping the trajectory of the metaverse in manufacturing, leveraging their expertise in cloud infrastructure, rendering technologies, and digital twin solutions.

Recent Developments

Acquisitions and Strategic Partnerships:

- Microsoft’s Acquisition: In a significant move, Microsoft acquired Activision Blizzard, aiming to boost its gaming business and accelerate the development of the metaverse across various platforms including mobile, PC, cloud, and console.

- Nvidia’s Partnerships: Nvidia announced partnerships with Blender and Adobe, enhancing the NVIDIA Omniverse, a platform designed to facilitate collaboration and simulation across various industries.

Technological Developments and Market Growth:

- The VR segment continues to dominate the Metaverse market due to its ability to provide immersive experiences, which are crucial for realistic training simulations and virtual product design in manufacturing.

- Predictions indicate significant growth in MR (Mixed Reality) technology, which blends virtual and real-world elements, enhancing user engagement and interactive experiences in industrial settings.

Use Cases

Digital Twins and Advanced Simulations:

The industrial metaverse facilitates the creation of digital twins, which are high-fidelity virtual models of physical systems. These enable manufacturers to simulate processes and predict outcomes without physical trials, reducing costs and time-to-market. Companies are leveraging digital twins to improve everything from product design to maintenance and troubleshooting.

VR/AR for Training and Operations:

Virtual Reality (VR) and Augmented Reality (AR) are being used extensively for training employees, allowing them to gain hands-on experience in a controlled, virtual environment. This approach significantly cuts down training costs and improves safety by allowing workers to practice in risk-free simulations. AR is particularly valuable for providing real-time assistance and guidance on the manufacturing floor, enhancing operational efficiency and reducing errors.

Remote Collaboration:

The metaverse enables remote teams to collaborate more effectively, regardless of their physical location. Teams can interact with 3D models and simulations in real-time, making collaborative design and troubleshooting more intuitive and productive. This not only speeds up the development process but also helps in maintaining high standards of quality control across geographically dispersed teams.

Enhanced Monitoring and Maintenance:

Leveraging IoT and AR technologies, manufacturers can implement systems that allow for real-time monitoring and predictive maintenance of equipment. This technology predicts failures before they occur, significantly reducing downtime and maintenance costs.

Customer Interaction and Customization:

Manufacturers can use the metaverse to offer customers unique, immersive experiences, such as virtual tours of production facilities or interactive customization of products. This not only enhances customer engagement but also enables more personalized products and services.

Key Players Analysis

Microsoft Corporation

Microsoft Corporation is actively shaping the industrial metaverse within the manufacturing sector through its integration of advanced technologies and strategic partnerships. The company focuses on leveraging digital twins, AI, and mixed reality tools like HoloLens 2 to enhance operational efficiency and innovation in manufacturing processes. A key example of Microsoft’s commitment is its collaboration with various industry leaders to integrate and optimize manufacturing operations using the Microsoft Cloud and Azure IoT technologies, which facilitate better data management and operational insights.

Recent developments have seen Microsoft making significant strides in this area, including its prominent participation at events like Hannover Messe 2023, where it demonstrated various applications of the industrial metaverse in manufacturing. These applications aim to unlock innovation, create resilient supply chains, and enable intelligent factories, ultimately modernizing digital sales and services. Additionally, Microsoft’s acquisition of Activision Blizzard underlines its strategy to enrich its technological ecosystem, likely benefiting its metaverse initiatives by enhancing interactive content and software capabilities

Unity Technologies

Unity Technologies is actively shaping the metaverse in the manufacturing sector through strategic partnerships and technological innovations. A notable development is Unity’s global alliance with Capgemini, established to design and scale tailored metaxeverse solutions across various industries, including manufacturing. This partnership aims to leverage Unity’s real-time 3D (RT3D) content creation platform to enhance digital customer and employee experiences, optimizing processes like engineering, manufacturing, and operations.

Unity is also enhancing its offerings with workshops and educational content focused on the industrial applications of augmented reality (AR), virtual reality (VR), mixed reality (MR), and extended reality (XR). These initiatives are designed to empower creators and industries to integrate immersive and interactive technologies into their workflows, thereby facilitating more efficient design, prototyping, and training processes.

Additionally, Unity’s engagement in the manufacturing metaverse includes driving the adoption of digital twin technologies. These technologies are pivotal for improving operational efficiencies and enabling simulations that optimize manufacturing outcomes. By focusing on these innovative areas, Unity is helping manufacturing firms transition to more integrated and technologically advanced operations.

NVIDIA Corporation

NVIDIA Corporation is actively contributing to the Metaverse in the manufacturing sector through its partnerships and technological advancements, particularly with its NVIDIA Omniverse platform. Recently, NVIDIA has partnered with Siemens to enhance industrial automation using AI-driven digital twin technology, which integrates NVIDIA’s powerful AI and Omniverse platforms to create fully-fidelity live digital twins. This partnership aims to transform manufacturing processes by improving productivity and process across the product lifecycle from design through to operation.

Additionally, NVIDIA has launched Omniverse Cloud Services to facilitate the creation and operation of industrial metaverse applications. This platform provides essential tools for 3D design and collaborative projects, which are accessible globally, supporting industries like manufacturing to innovate and optimize operations remotely and in real-time. These initiatives are part of NVIDIA’s broader effort to empower industries by leveraging its advanced AI and computing capabilities, thereby significantly impacting how manufacturing industries innovate and operate.

PTC Inc

PTC Inc. is significantly enhancing its influence in the Metaverse within the manufacturing sector through strategic acquisitions and a focused push on digital transformation. Recently, PTC invested over $3 billion in acquisitions and organic development to bolster its digital capabilities. Key acquisitions include Onshape, a cloud-native product development platform; Arena, a cloud-native PLM and QMS solution; Codebeamer, an ALM platform; and ServiceMax, a field service management platform. These acquisitions complement PTC’s existing portfolio, including the IoT platform ThingWorx and the AR software Vuforia, enabling PTC to offer comprehensive digital solutions across the manufacturing lifecycle.

PTC’s strategy emphasizes the use of a digital thread throughout the product lifecycle and a transition to SaaS solutions, aiming to improve efficiency, sustainability, and compliance for industrial companies. The acquisition of ServiceMax, valued at nearly $1.5 billion, is particularly notable as it integrates closely with PTC’s Windchill PLM software to enhance lifecycle management with better service strategies and predictive maintenance capabilities.

Moreover, PTC is actively engaging in the development of industrial Metaverse applications, focusing on enhancing collaboration between digital and physical realms to solve real-world problems efficiently and cost-effectively.

Magic Leap Inc

Magic Leap Inc. has been actively advancing its presence in the Metaverse within the manufacturing sector through significant developments in augmented reality (AR) technology. The company’s latest offering, Magic Leap 2, showcases their commitment to enhancing industrial applications of AR. This device is noted for its lightness and small size, aimed at enterprise use, with improved features like Dynamic Dimming™ technology which helps display clearer images in bright environments, and a broad field of view up to 70 degrees to enhance user experience in industrial settings.

Recent activities include collaborating with companies across various sectors, such as healthcare and manufacturing, to optimize operations like training and maintenance through AR. These collaborations are part of Magic Leap’s strategy to embed AR more deeply into business workflows, thus driving greater value and productivity enhancements.

Magic Leap has also been expanding its intellectual property portfolio, emphasizing the development of advanced AR optics. This strategic focus is intended to maintain their competitive edge in the rapidly evolving AR landscape, which is increasingly integral to the industrial metaverse applications.

Siemens AG

Siemens AG is significantly enhancing its footprint in the Metaverse within the manufacturing sector through strategic investments and innovative partnerships. Recognized as a leader in the industrial metaverse market by PAC RADAR, Siemens is applauded for its clear strategy and broad portfolio that actively shapes the industrial metaverse space. Siemens’ strategic partnership with NVIDIA has been pivotal, integrating NVIDIA’s Omniverse platform with Siemens Xcelerator to develop advanced digital twins and AI-driven solutions that streamline production and product lifecycle processes across various industries.

Additionally, Siemens has announced substantial investments, such as a €1 billion commitment to create a blueprint for the industrial metaverse in the Nuremberg metropolitan region. This investment will focus on merging digital advancements with physical manufacturing processes to enhance operational efficiency and sustainability. These initiatives are part of Siemens’ broader effort to drive digital transformation across its operations globally, leveraging cutting-edge technologies to revolutionize traditional industrial and manufacturing practices.

Autodesk Inc

Autodesk Inc. has been actively participating in the Metaverse within the manufacturing sector, focusing on real-time 3D visualization and digital twin technologies. A significant partnership between Autodesk and Epic Games, announced in 2022, has enabled easier creation of real-time 3D visualizations from Autodesk’s Revit models using Twinmotion, enhancing the utility and accessibility of digital twins in architectural design.

Additionally, Autodesk has been investing in volumetric video technology, which is expected to play a crucial role in developing more immersive AR and VR experiences. These developments aim to streamline the integration of the physical and digital worlds, thereby facilitating better design, planning, and simulation processes in manufacturing and construction industries. This strategic focus underscores Autodesk’s commitment to advancing digital transformation in the industrial and construction sectors through innovative metaverse applications.

EON Reality Inc

EON Reality Inc. has been making significant strides in the Metaverse within the manufacturing sector, focusing particularly on education and training through virtual and augmented reality (VR/AR) technologies. A key development is their EON-XR platform, which serves as a primary delivery vehicle for immersive XR education and industry solutions. EON Reality has expanded its global impact through partnerships, such as with the Manufacturing, Engineering and Related Services Sector Education and Training Authority (merSETT) in South Africa. This collaboration aims to utilize EON Reality’s XR solutions to enhance skills development and training in high-demand sectors, thereby addressing skills gaps and improving employee safety and efficiency through simulated environments.

Furthermore, EON Reality introduced the EON Metaverse Builder at the EON Experience Fest, demonstrating their commitment to expanding the capabilities within the Knowledge Metaverse. This tool allows for the creation of detailed and immersive educational and industrial environments, enhancing the learning and training experience across various fields, including manufacturing.

HTC Corporation

HTC Corporation has been advancing its presence in the Metaverse within the manufacturing sector through its innovative virtual reality products like the HTC Vive. The company has introduced several improvements to the Vive, such as enhanced display resolution, wider field of view, and better tracking capabilities.

These enhancements aim to deliver more immersive VR experiences that are critical in industrial applications for design, training, and operations. HTC’s commitment to VR innovation is integral to its strategy, impacting various industries by transforming how they engage with digital environments.

Conclusion

In conclusion, the Metaverse in Manufacturing Market is poised for substantial growth, driven by technological innovations and increasing investments. While challenges exist, the potential benefits in terms of efficiency, safety, and innovation are expected to propel the market forward, making it a pivotal area for future industrial advancements.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)