Table of Contents

Introduction

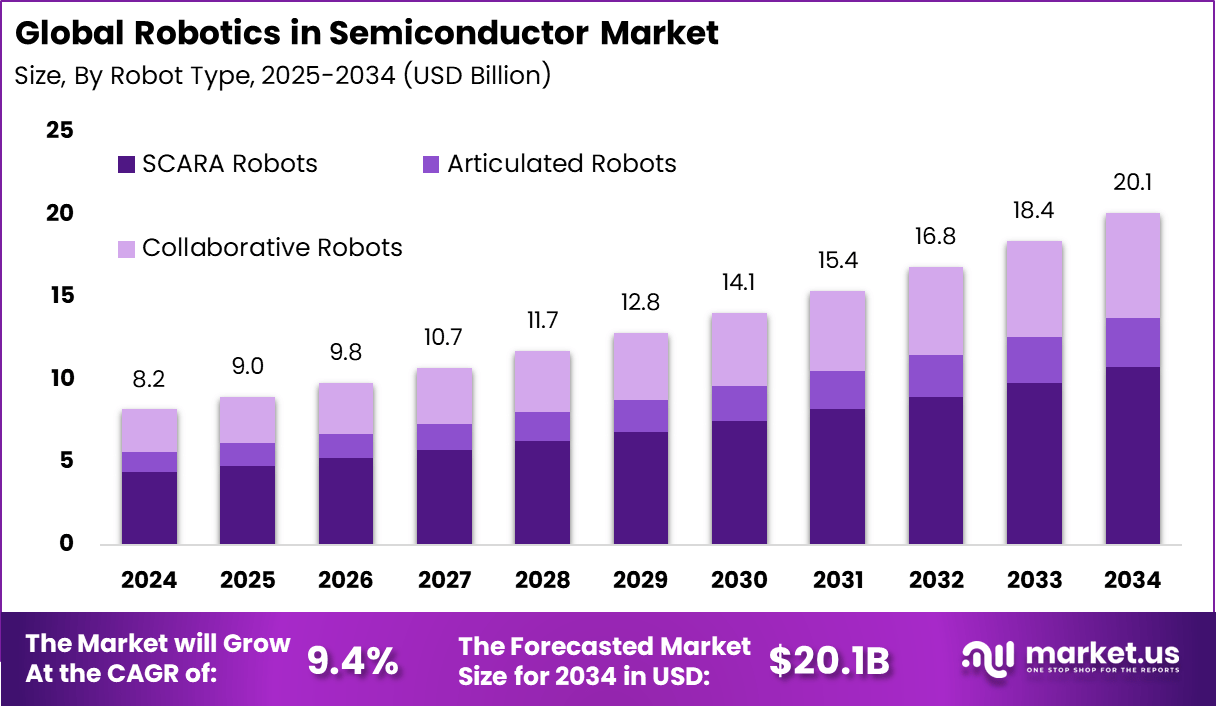

The Global Robotics in Semiconductor Market generated USD 8.2 billion in 2024 and is projected to grow from USD 9.0 billion in 2025 to USD 20.1 billion by 2034, at a CAGR of 5.94%. APAC dominated with a 75.8% share worth USD 6.2 billion due to strong fab concentration and rising automation needs. Increasing wafer complexity, contamination-free handling requirements, and transition toward smaller nanometer nodes continue driving robotics demand across fabrication and assembly processes.

How Growth Is Impacting the Economy

Growth in robotics is transforming global economic structures by boosting productivity, reducing manual labor dependency, and improving supply-chain resilience. Automated fabs support national competitiveness in APAC, North America, and Europe by enhancing throughput and yield stability.

Investments in 300mm and upcoming 450mm wafer lines stimulate upstream industries such as sensors, precision engineering, and materials technology. Countries increasing domestic chip production enjoy stronger economic security and reduced import reliance. Robotics also creates new employment roles in engineering, predictive maintenance, and system design, balancing automation’s efficiency benefits with workforce development.

➤ Smarter strategy starts here! Get the sample – https://market.us/report/robotics-in-semiconductor-market/free-sample/

Impact on Global Businesses

Businesses worldwide face rising initial capital expenditures as they adopt clean-room robots, high-precision actuators, and AI inspection systems. Supply chains are shifting toward vendors specializing in micro-motion components, servo motors, and high-reliability robotics assemblies. Improvements include higher wafer handling yields, greater lithography accuracy, and faster process cycle times. Industries relying on AI chips, automotive electronics, and mobile devices benefit from consistent semiconductor output. Many semiconductor manufacturers are redesigning production layouts to support automation-first workflows, enabling scalable and globally synchronized operations.

Strategies for Businesses

Companies should adopt modular and AI-enabled robotics to improve flexibility and precision. Building multi-sourcing strategies helps reduce geopolitical risks and supply disruptions. Upskilling workers in robot operation and maintenance ensures reliable fab operations. Collaborations with vision-system and sensor providers can improve yield outcomes. Redesigning fab environments around automated movement, inspection, and handling enhances predictable performance and reduces contamination.

Key Takeaways

• Robotics increases semiconductor yield and manufacturing stability.

• APAC remains the dominant automation hub.

• Automation reduces contamination and manual error.

• Supply chains are shifting toward high-precision component suppliers.

• AI-enabled robotics enhances long-term scalability.

➤ Unlock growth secrets! Buy the full report – https://market.us/purchase-report/?report_id=169308

Analyst Viewpoint

Current adoption is strong as fabs pursue higher precision, smaller nodes, and improved throughput. Robotics is now essential for advanced-node manufacturing, where manual handling is no longer viable. Looking ahead, AI-driven robotic systems, autonomous material movement, and automated defect analysis will continue to expand. Supportive semiconductor policies worldwide will accelerate fab construction, ensuring robotics remains a critical foundation for next-generation manufacturing.

Use Case and Growth Factors

| Use Case | Growth Factor |

|---|---|

| Clean-room wafer handling | Need for contamination-free precision |

| Robotic lithography loading | Alignment accuracy for advanced nodes |

| Automated inspection and metrology | AI-enhanced defect detection |

| Autonomous material movement | Rising fab output and logistics optimization |

| Chip packaging and assembly | Miniaturization increasing micro-handling demand |

Regional Analysis

APAC leads the market with more than 75.8% share due to major fabs concentrated in China, Taiwan, Japan, and South Korea. North America is growing through national semiconductor programs and new fab investments. Europe shows upward momentum supported by automotive and industrial chip demand. Middle Eastern regions are exploring robotics-based manufacturing models as part of long-term semiconductor capability building.

➤ Want more market wisdom? Browse reports –

- VR Esports Venue Insurance Market

- PCB Manufacturer Insurance Market

- Bank Fee Analysis Software Market

- AI Inference Gateways Market

Business Opportunities

Opportunities exist in clean-room robotics, AI-driven inspection systems, automated wafer handling, packaging robotics, and predictive maintenance platforms. Increased interest in 3D packaging, chiplets, and heterogeneous integration fuels demand for micro-precision robotics. Government incentives supporting new fab construction open strong markets for robotics integrators and component suppliers.

Key Segmentation

The market includes robotic arms, wafer-handling robots, inspection robots, automated transport vehicles, and packaging robotics. Applications span wafer fabrication, lithography support, deposition, etching, assembly, testing, and internal material flow. End-users include semiconductor fabs, foundries, IDMs, OSAT companies, and equipment manufacturers, reflecting diverse automation needs across the value chain.

Key Player Analysis

Leading players emphasize precision robotics engineered for contamination-free semiconductor environments. Their strategies include improving motion accuracy, integrating AI diagnostics, and strengthening vacuum-compatible designs. Many develop modular robotic platforms and predictive maintenance features to support scalability. Long-term relationships with fabs ensure stable demand and accelerate global automation adoption.

- KUKA Robotics

- FANUC Corporation

- ABB Ltd.

- Universal Robots

- Yaskawa Electric Corporation

- Omron Corporation

- Kawasaki Robotics

- Stubli

- Acieta

- Bastian Solutions

- Comau (FCA)

- Balyo

- BA Systems

- DF Automation

- Omron Adept Technologies

- READY Robotics

- Others

Recent Developments

• January 2024 – AI-driven defect inspection robotics introduced for sub-10nm wafers.

• March 2024 – Modular wafer-transfer robots released for 300mm and 450mm production lines.

• June 2024 – Autonomous intralogistics robots deployed for high-volume fabs.

• September 2024 – New vacuum-optimized robotic arm series launched.

• November 2024 – Predictive maintenance AI integrated into fab-grade robotics systems.

Conclusion

The Robotics in Semiconductor Market is rapidly expanding as fabs pursue higher precision, cleaner production, and faster throughput. With strong APAC leadership and global investment momentum, robotics will remain the backbone of semiconductor manufacturing growth through 2034 and beyond.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)