Table of Contents

Introduction

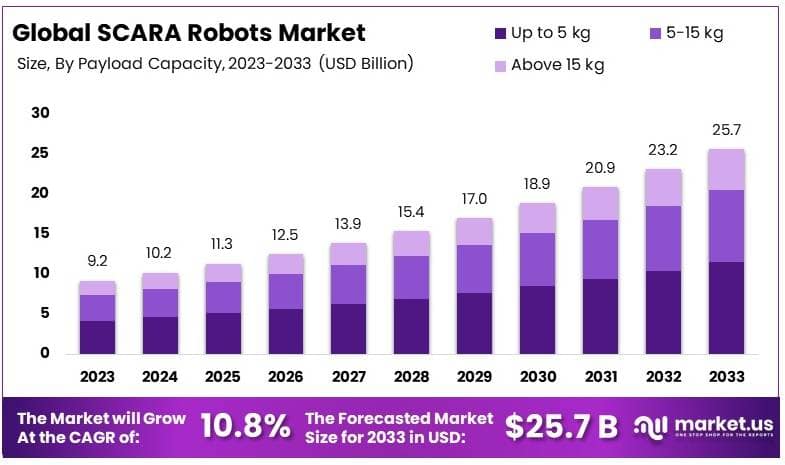

The Global SCARA Robots Market is poised for significant expansion, projected to grow from USD 9.2 billion in 2023 to approximately USD 25.7 billion by 2033, registering a CAGR of 10.8% during the forecast period (2024–2033). SCARA (Selective Compliance Assembly Robot Arm) robots are becoming increasingly essential in assembly, pick-and-place, and material handling operations, especially across electronics, automotive, and healthcare sectors. Their speed, precision, and cost-effectiveness make them ideal for high-throughput manufacturing environments.

How Growth is Impacting the Economy

The rise of SCARA robots is catalyzing efficiency, reshaping labor dynamics, and contributing to industrial output. With manufacturers seeking automation to reduce operational costs and increase throughput, SCARA adoption supports GDP growth by boosting productivity across developing and developed economies. Economies like China, Germany, and the US are investing heavily in smart factories, which incorporate SCARA robots to reduce cycle times and improve yield. This automation reduces reliance on manual labor for repetitive tasks, shifts workforce demand toward higher-skilled roles, and helps counter labor shortages in advanced economies. Additionally, supply chains are becoming more resilient as robotic precision improves inventory control and reduces wastage.

➤ Smarter strategy starts here! Get the sample – https://market.us/report/scara-robots-market/free-sample/

Impact on Global Businesses

Businesses globally are experiencing mixed effects from SCARA deployment. On one side, rising capital expenditure for robotic integration and maintenance training add to costs. However, the long-term gains through faster throughput, fewer errors, and 24/7 uptime outweigh initial investments. Supply chains are evolving as SCARA robots facilitate just-in-time production models, minimize overstocking, and enable agile response to demand changes. Sector-wise, electronics benefits from micro-assembly and fast cycle times, automotive sees value in precise part handling, while pharma and food industries gain hygiene-compliant automation with consistent accuracy.

Strategies for Businesses

To succeed in the SCARA market evolution, companies should focus on modular automation, allowing flexibility in production lines. Investing in collaborative robot interfaces, predictive maintenance, and AI-integrated vision systems will extend robot lifespans and performance. Training staff for robot programming and real-time monitoring platforms ensures smooth integration. Choosing suppliers that offer custom payload ranges and compact footprints can help businesses adapt across different environments. Finally, leveraging government grants or tax incentives for smart manufacturing can offset initial costs.

Key Takeaways

- SCARA robots market to reach USD 25.7 billion by 2033

- CAGR of 10.8% from 2024 to 2033

- Electronics, automotive, and pharma sectors are among the key adopters

- SCARA robots enable higher throughput and labor cost savings

- Integration of AI and IoT is a major growth enabler

➤ Unlock growth secrets! Buy the full report – https://market.us/purchase-report/?report_id=129121

Analyst Viewpoint

Current adoption of SCARA robots is largely driven by automation mandates, labor constraints, and quality assurance requirements. Presently, industries with high-volume repetitive tasks are the fastest adopters. Looking ahead, integration with AI, 3D vision systems, and cloud platforms is expected to elevate SCARA robots beyond simple automation—toward intelligent, autonomous units capable of decision-making and error correction. The future is promising, especially as smaller enterprises begin to adopt compact and low-cost SCARA solutions.

Use Case and Growth Factors

| Use Case | Growth Factor |

|---|---|

| Electronics Assembly | High-speed precision in component placement |

| Automotive Manufacturing | Cost-effective part handling with fast repeatability |

| Pharmaceutical Packaging | Sterile and accurate handling of delicate materials |

| Food & Beverage Sorting | Hygiene compliance and quick product sorting |

| Consumer Goods Inspection | AI-integrated vision for defect detection |

| E-commerce Order Fulfillment | Compact robots for efficient bin-picking |

Regional Analysis

Asia Pacific holds the largest share in the SCARA robots market, led by China, Japan, and South Korea, due to their dominance in electronics and automotive manufacturing. Europe is also expanding, especially in Germany and Italy, where Industry 4.0 initiatives drive robot deployment. North America follows closely, with growing demand in precision packaging and medical device assembly. Emerging economies in Southeast Asia and Latin America are seeing rapid adoption as SCARA solutions become more affordable and energy-efficient.

➤ More data, more decisions! see what’s next –

Business Opportunities

Vast opportunities lie in SME-focused SCARA solutions, where compact, low-payload robots cater to mid-sized factories. Integration of machine learning-based vision and plug-and-play modularity can unlock new revenue streams for vendors. The market also presents room for aftermarket services like maintenance, software upgrades, and robot-as-a-service (RaaS) models. With sustainability becoming critical, lightweight and energy-efficient SCARA designs are gaining traction, especially in Europe and Japan. As global automation demand rises, players offering end-to-end solutions from integration to analytics will thrive.

Key Segmentation

The SCARA robots market is segmented by payload, application, end-use industry, and region.

- By Payload: Up to 5 kg, 5–15 kg, and above 15 kg—where low payload robots dominate due to electronics sector demand.

- By Application: Material handling, assembly, packaging, inspection, and palletizing—assembly and pick-and-place being most prominent.

- By End-Use: Automotive, electronics, pharmaceuticals, food & beverages, and logistics.

- By Region: Asia Pacific leads, followed by Europe and North America, with emerging demand in Latin America and MEA.

Key Player Analysis

Top players are focusing on expanding their automation portfolios, offering energy-efficient, high-speed SCARA models tailored to industry-specific needs. Strategic alliances with component suppliers, software firms, and system integrators enable a full-stack automation solution. Leading vendors are investing in AI-powered visual inspection modules and launching collaborative SCARA variants for shared workspaces. Geographic expansion into Southeast Asia, India, and Eastern Europe is becoming critical, while innovation cycles are shortening to meet fast-evolving industrial needs.

- ABB Ltd

- Denso Corporation

- Epson Robots

- FANUC Corporation

- Hiwin Corporation

- SMC Corporation

- Yaskawa Electric Corporation

- Seiko Epson Corporation

- Kawasaki Robotics

- OMRON Corporation

- Mitsubishi Electric Corporation

- KUKA AG

- Staubli International AG

- Other Key Players

Recent Developments

- January 2024: Launch of compact SCARA robot with 3kg payload for electronics micro-assembly

- March 2024: Introduction of SCARA models with integrated AI visual guidance systems

- May 2024: Partnership announced between SCARA vendor and cloud analytics firm for smart diagnostics

- July 2024: Expansion of SCARA production facility in Vietnam to meet APAC demand

- September 2024: New SCARA robot variant designed for sterile pharmaceutical environments

Conclusion

The SCARA robots market is accelerating rapidly, driven by industrial automation, labor efficiency, and precision demands. Businesses investing early in smart, scalable, and AI-ready SCARA solutions will be best positioned to lead in the future of automated manufacturing.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)